Wall Sheathing Nailing Pattern

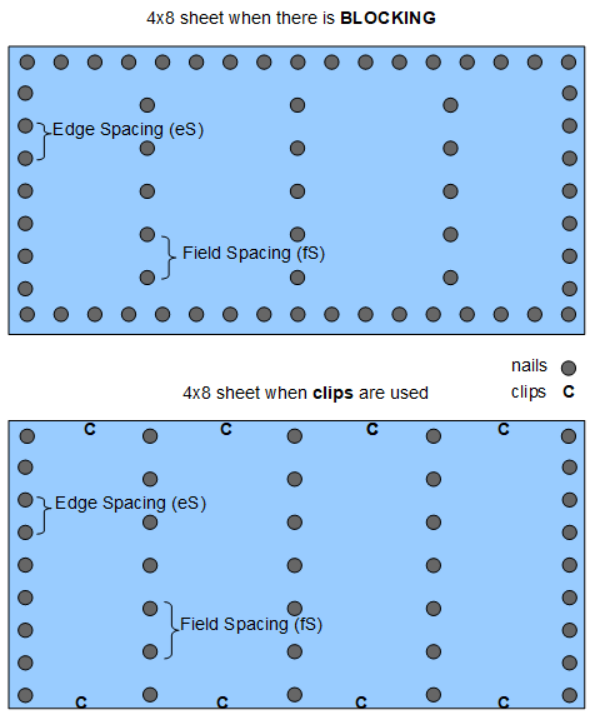

Wall Sheathing Nailing Pattern - There are numerous advantages to using continuously sheathed plywood or osb walls as a nail base for brick ties, siding and trim: Web continuous sheathing—sheathing all exterior walls with wood structural panels, including above and below openings and gable ends—is a practical and effective way to meet the code at an affordable cost. With overhead powerlines, a found. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. For a structural panel, all edges must be supported; This installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. Web with integrated structural, water and air management layers, zip system products offer interchangeable options for optimal roof and wall performance. Once the sheathing is fastened, prep the seams for tape. What’s the permeability of zip system sheathing panels? Along the edges the nails hold the sheathing tightly to the framing and must be 3/8” in from the. Web installation manual | zip system sheathing and tape. To access printing capabilities, please subscribe to a digital codes premium subscription. Ie, if you have 8' sheathing and 9' walls, you must block where the sheet ends. Web continuous sheathing—sheathing all exterior walls with wood structural panels, including above and below openings and gable ends—is a practical and effective way. Ie, if you have 8' sheathing and 9' walls, you must block where the sheet ends. When i order nails for wall sheathing, i don’t order them by penny weight; Nails at the corners must be 3/8” from the corner; Installation manual | zip system sheathing and tape. Web for example, an 8d common nail is 2 1/2 inches (length). Web the nails needed for sheathing on a wall calculator computes the approximate number of nails needed to nail 4x8 sheets to wall studs based on the dimensions of the wall, spacing of nails on the edges and field of the 4x8, and whether blocking or clips are use. Once the sheathing is fastened, prep the seams for tape. Angling. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. Ie, if you have 8' sheathing and 9' walls, you must block where the sheet ends. 80 ksi for shank diameter of 0.192 inch (20d common nail), 90 ksi for shank diameters larger than 0.142 inch but. They hold the corner down and keep it from lifting. Start by holding the corner of each sheet up to the line and setting one nail, and then lift the rest of the panel until it’s lined up and continue nailing. Web continuous sheathing—sheathing all exterior walls with wood structural panels, including above and below openings and gable ends—is a. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Installation manual | zip system sheathing and tape. Instead, i order by the length and diameter. Nailing the sheathing to the mudsills provides a structural connection between the walls. Inspect all nail patterns, ensuring they’re set correctly before moving forward. Ie, if you have 8' sheathing and 9' walls, you must block where the sheet ends. Refer to lateral force resisting systems section for screw requirements for shear wall applications. Nailing the sheathing to the mudsills provides a structural connection between the walls and the foundation. They hold the. Web when framing is done and you’re ready to install zip system sheathing on a house, you should first snap a level line on each wall to ensure your first course of panels is straight. Choose units and enter the following: Angling the nailer helps to ensure the nails hit the studs along the ends of the sheets. Nails at. Nails at the corners must be 3/8” from the corner; 80 ksi for shank diameter of 0.192 inch (20d common nail), 90 ksi for shank diameters larger than 0.142 inch but not larger than 0.177 inch, and 100 ksi for. Three panel thicknesses with various dimensional options let you choose the right panel for each design and application. Nails used. For a structural panel, all edges must be supported; This installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. Choose units and enter the following: Once the sheathing is fastened, prep the seams for tape. There are numerous advantages to using continuously sheathed plywood or osb walls as a nail base. Three panel thicknesses with various dimensional options let you choose the right panel for each design and application. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. Start by holding the corner of each sheet up to the line and setting one nail, and then lift the rest of the panel until it’s lined up and continue nailing. Instead, i order by the length and diameter. Angling the nailer helps to ensure the nails hit the studs along the ends of the sheets. Web for example, an 8d common nail is 2 1/2 inches (length) x.131 inch (diameter), whereas an 8d box nail is 2 1/2 inches (length) x.113 inch (diameter). For a structural panel, all edges must be supported; Icc digital codes is the largest provider of model codes, custom codes and standards used worldwide to construct safe, sustainable, affordable and resilient structures. 80 ksi for shank diameter of 0.192 inch (20d common nail), 90 ksi for shank diameters larger than 0.142 inch but not larger than 0.177 inch, and 100 ksi for. Web installation manual | zip system sheathing and tape. Inspect all nail patterns, ensuring they’re set correctly before moving forward. Web no, the integrated protective overlay of a zip system wall sheathing panel is permeable to allow for drying to the outside. Web printing is a feature of digital codes premium. With overhead powerlines, a found. The nails should be about 3/8 in. Web the most critical nails are at the corners and along edges in contact with the framing.

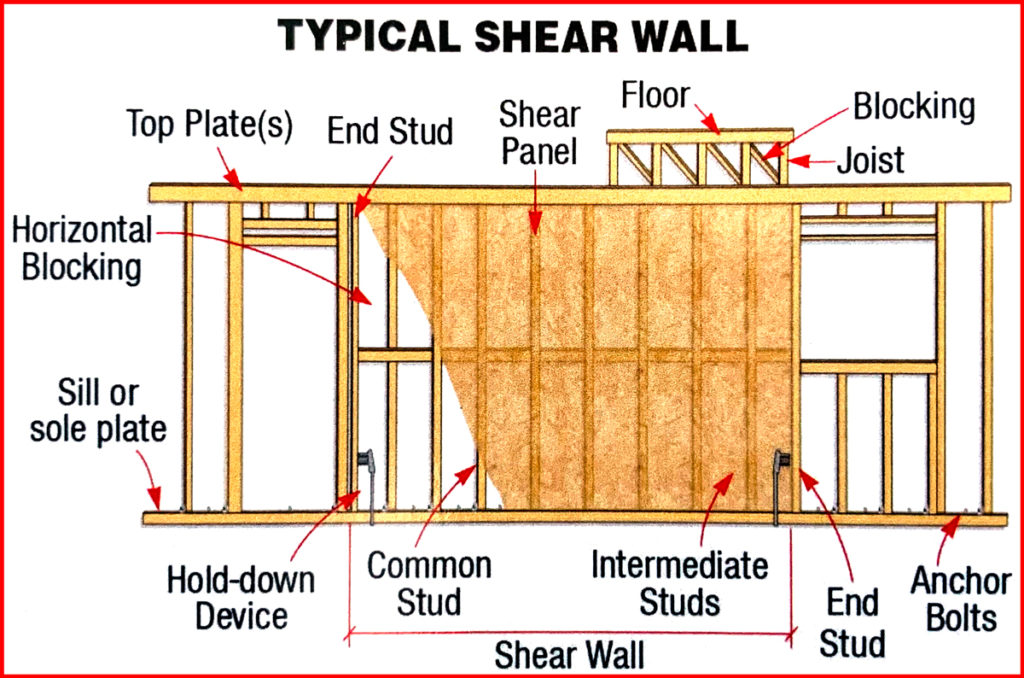

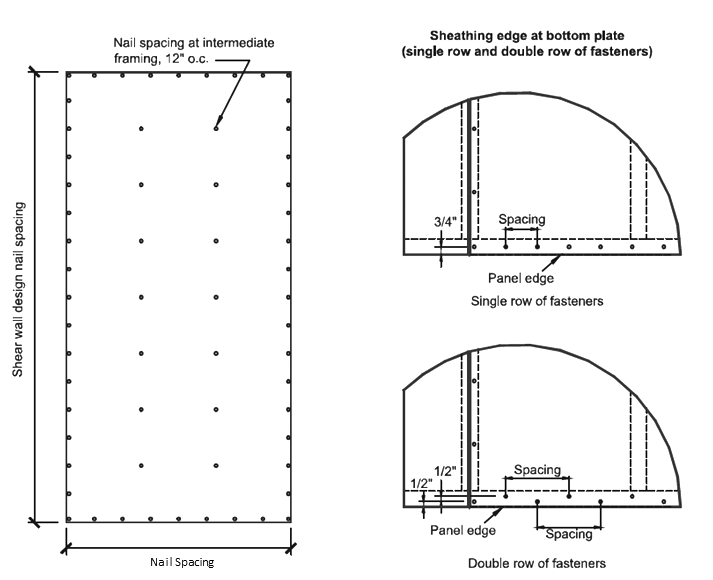

Shear Walls, The Basics JLC Online

Nailing Pattern For Osb Wall Sheathing

Nails for Wall Sheathing

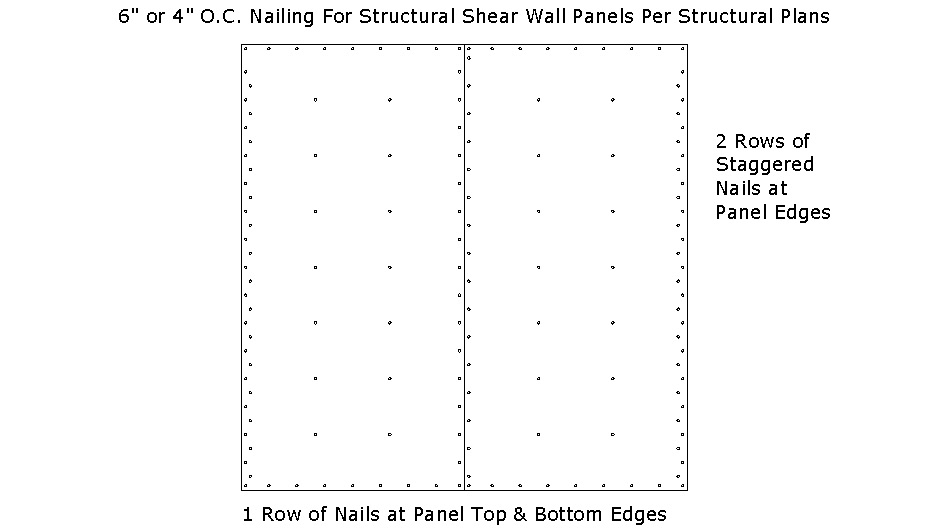

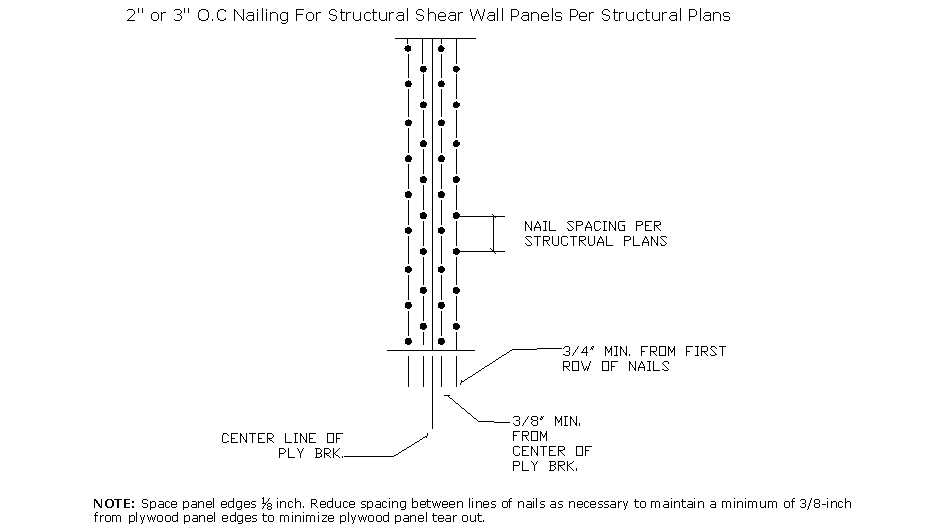

Structural Shear Wall Nailing in Commercial and Residential Framing

Wall Sheathing Nailing Pattern Timber Structures / Estruturas de Ma…

Shear Walls What are they? Lynn Engineering

Structural Shear Wall Nailing in Commercial and Residential Framing

Nailing Pattern For Osb Wall Sheathing

Plywood Sheathing Nailing Pattern Nail Ftempo

Plywood Sheathing Nails Nail Ftempo

They Hold The Corner Down And Keep It From Lifting.

When I Order Nails For Wall Sheathing, I Don’t Order Them By Penny Weight;

Web For Example, Particleboard Wall Sheathing To Framing Requires 6D Common Or Deformed Nails Measuring 2″ × 0.113″ X 0.266″ Head, While Wood Structural Panel Exterior Wall Sheathing To Wall Framing Requires 8D Common Or Deformed Nails Measuring 2 1/2″ × 0.131″ X 0.281″ Head.

Not 2” Or 3” Or 4” But 3/8” From The Corner.

Related Post: