Diy Router Template

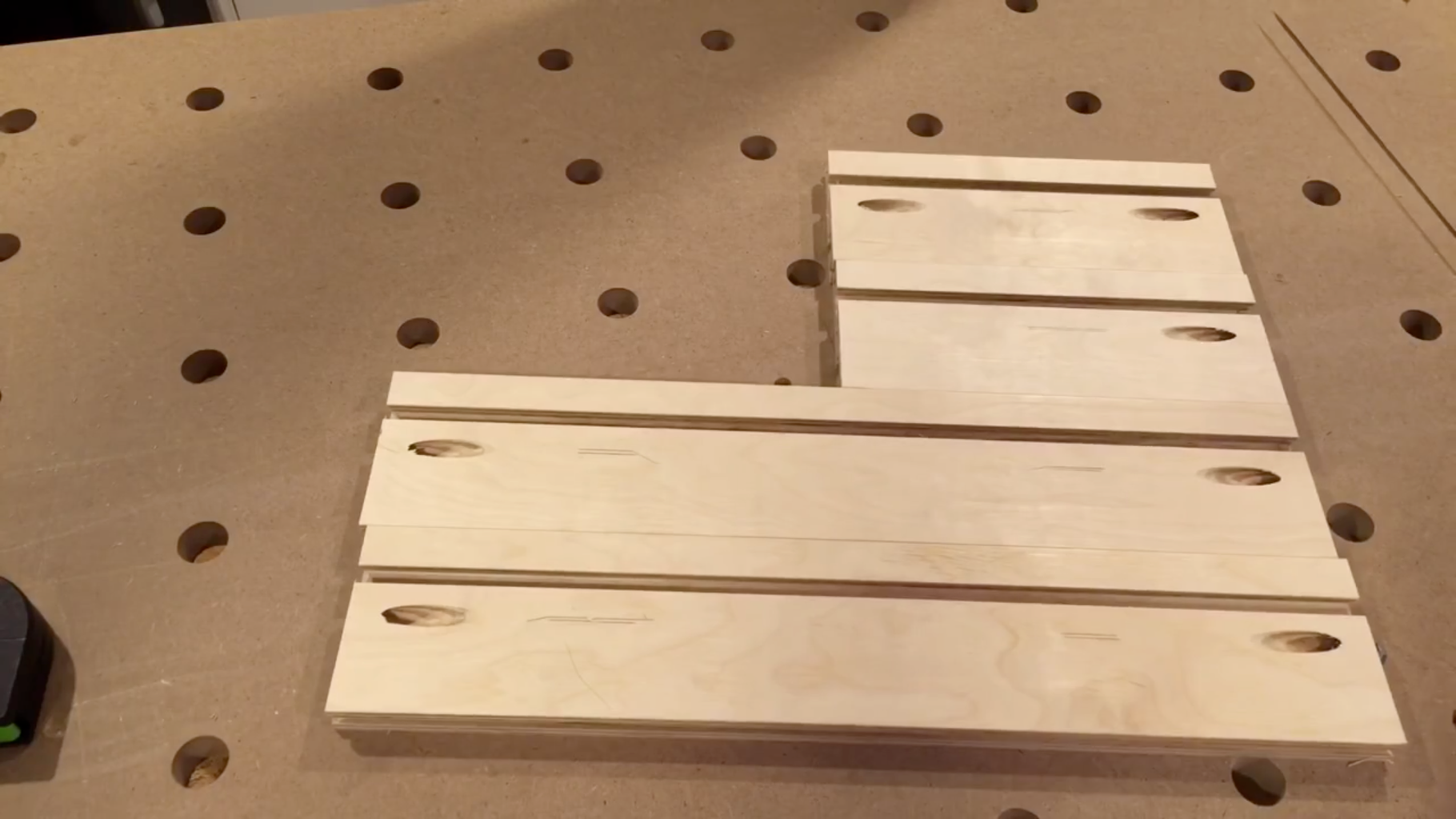

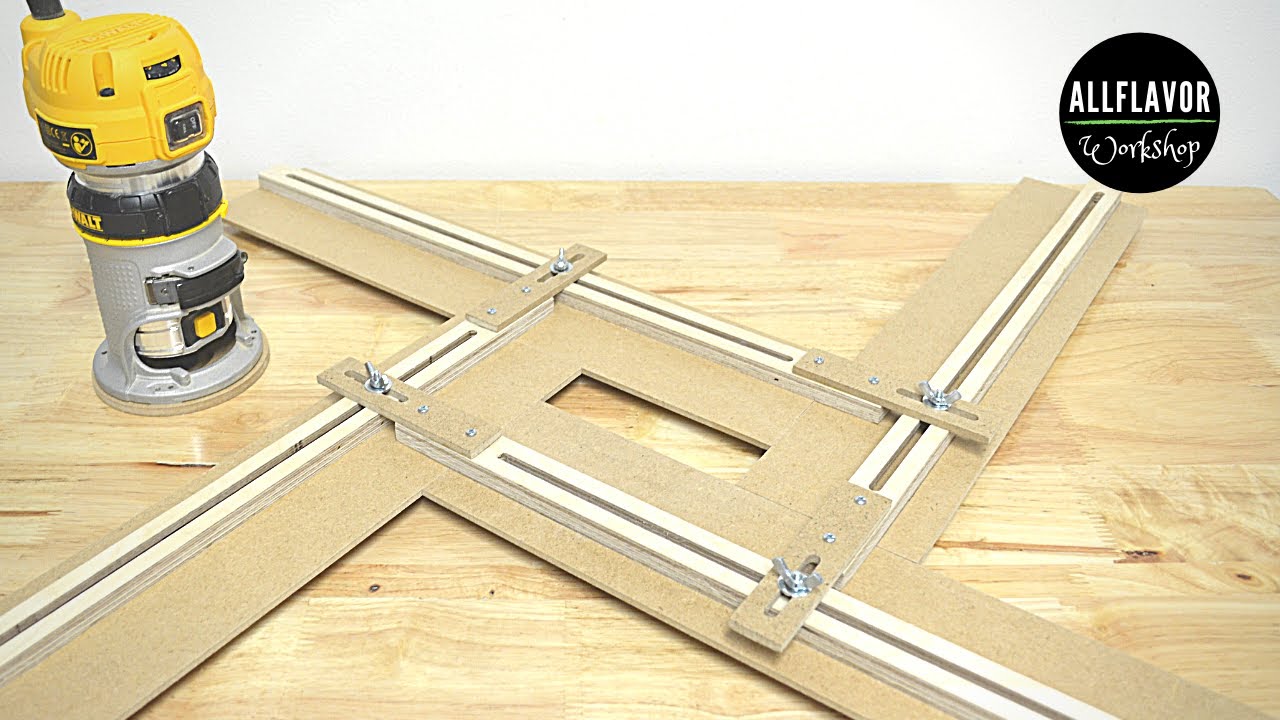

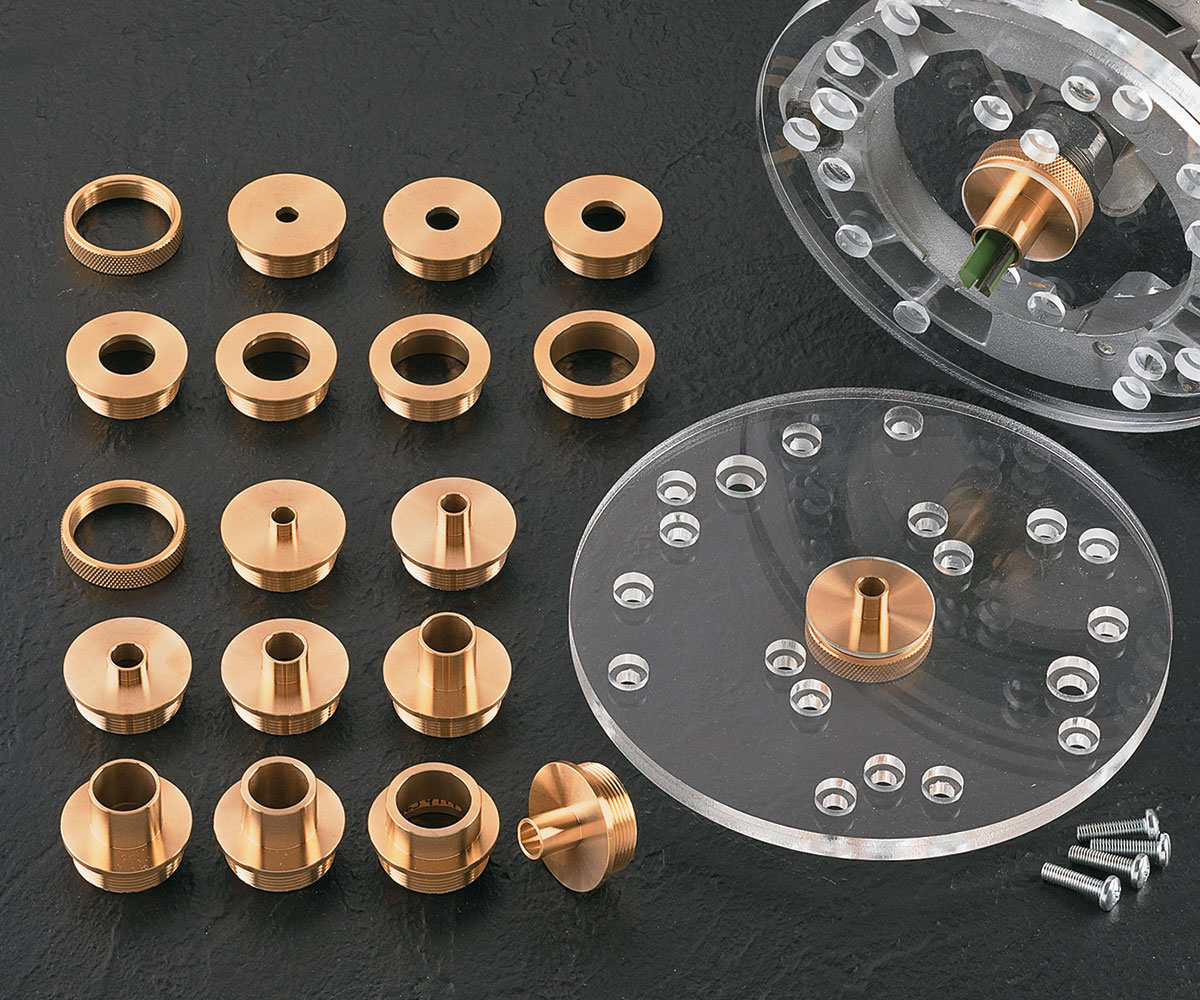

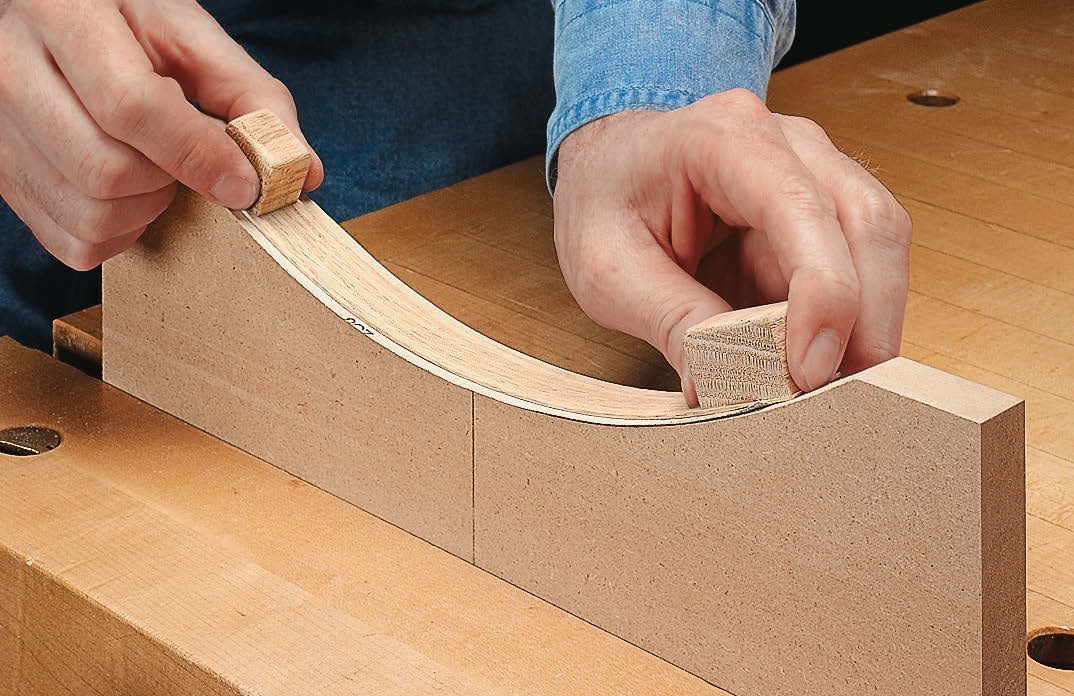

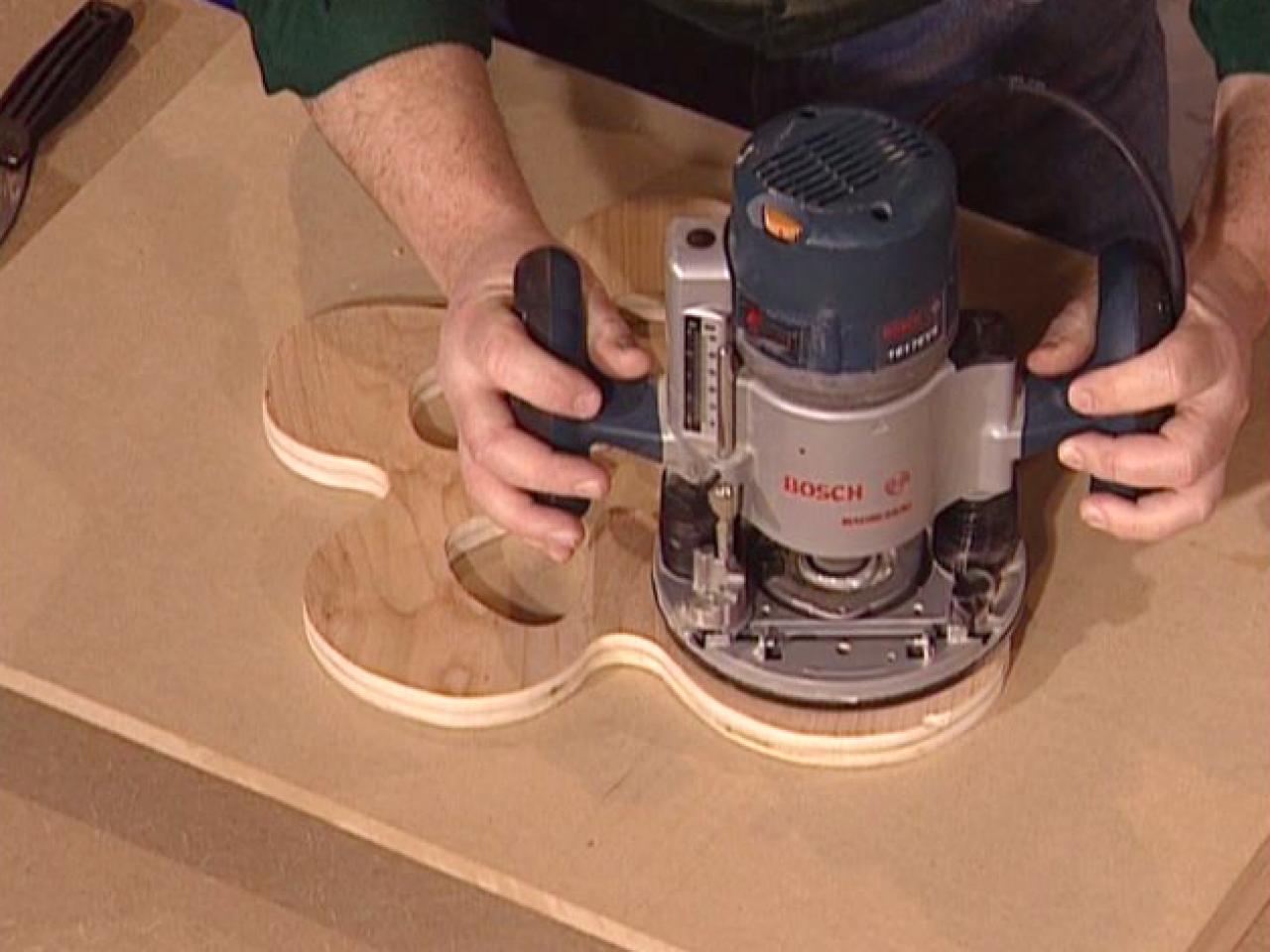

Diy Router Template - Template guide bushings turn your router into a pattern follower. Make a pass, inspect your work and make additional passes until all ridges and dimples are gone. For a detailed look at the profiles, check out the sketchup model in the next step! And the tightness of the curves you can achieve when routing will be determine by the bush’s outside diameter (od). Let the slide drop to the table and lock. Attach the template to your stock and, using a plunge router, position the guide in the hole. Attach the guides to the template base plates. Finally pick another thin piece and make an inlay piece from it. Web establish the required dimensions, draw the shape on your template and then add the offset. Then, pick a scrap and create a cavity. Screw the pattern onto the waste wood, set the depth of cut, clamp it up and have a shop vacuum nearby. This gives enough clearance for the bit to spin freely. Glue those together, and sand them flash. Now, templates can help you do three main things: Corners and detailed areas can lose their shape or get dinged if dropped. Make yourself a great looking template, and make it perfect. First, they can help you trace com. Make a pass, inspect your work and make additional passes until all ridges and dimples are gone. Then, pick a scrap and create a cavity. Here, we'll discuss how to make decorative shapes. Web the first cut will be about 5mm deep, half the thickness of the insert. **please click .more below to see full description**learn how to make and use router templates on your woodworking projects. Zero the gauge by setting it on a flat surface, for example, your tablesaw. One clamp holds the jig to the workpiece and does not allow. Web pick something easy, and something that you could knock out in a couple hours. Use an up cut spiral straight bit and. Make sure the bit is cutting into the workpiece, not the template. Now, templates can help you do three main things: My router lift, which is a jay bates design, is mounted in my outfeed assembly table. Web establish the required dimensions, draw the shape on your template and then add the offset. My router lift, which is a jay bates design, is mounted in my outfeed assembly table. Both prove easy to machine and offer greater stability than solid wood. The second one will be 5mm further toward the center, cutting completely through. One clamp holds. She's taking us back to basics, addressing a common. Web router templates make it easy to trace complex shapes and make multiple identical parts. Web make the initial cut: Web establish the required dimensions, draw the shape on your template and then add the offset. Attach the guides to the template base plates. On the end of each piece you drilled the hole in mark the centre of the wood at 1 3/4 inches from the end. Web now, templates can help you. Web bore a hole at least 1/4″ bigger than the cutter head on your router bit. Make the initial cut shallow and take your time to ensure accuracy. Use an. Then i used a combination of files and sandpaper to fine tune the template to fit the pickup. Finally pick another thin piece and make an inlay piece from it. Web bore a hole at least 1/4″ bigger than the cutter head on your router bit. Web router templates make it easy to trace complex shapes and make multiple identical. Plunge the bit into the stock and carefully rout out the waste. Connect all base plates together. Web i drilled a pilot hole first, so that i could use the scroll saw to cut out the center of my template. Make yourself a great looking template, and make it perfect. Web bore a hole at least 1/4″ bigger than the. Both prove easy to machine and offer greater stability than solid wood. If necessary, square up the corners with a chisel. On the end of each piece you drilled the hole in mark the centre of the wood at 1 3/4 inches from the end. Make sure the bit is cutting into the workpiece, not the template. I made a. Then, with the sleeve on the bushing, simply rout the outline of the recess and the remainder of the waste by following the template. Screw the pattern onto the waste wood, set the depth of cut, clamp it up and have a shop vacuum nearby. I make sure everything is correct by screwing the fixed base to the insert; Secure the acrylic plate with a couple of screws. I made a build video and tour video of the table, which is on my website. Rolling ladder & door hardware. Start to hollow out the bowl. On the end of each piece you drilled the hole in mark the centre of the wood at 1 3/4 inches from the end. Finally pick another thin piece and make an inlay piece from it. Web now, templates can help you. Zero the gauge by setting it on a flat surface, for example, your tablesaw. I’ve glued the printable template, pulling it back 15mm. Next, drill and countersink the pilot holes in the base plate for the mounting screws. Web pick something easy, and something that you could knock out in a couple hours. And the tightness of the curves you can achieve when routing will be determine by the bush’s outside diameter (od). For a detailed look at the profiles, check out the sketchup model in the next step!

Diy Router Templates

DIY Adjustable Router Template 10 Steps (with Pictures) Instructables

DIY Router Table 6 Steps (with Pictures) Instructables

DIY Router Guide • WoodArchivist

Router Template Guide WONDERFUL TEMPLATES

Router Template Guides Lee Valley Tools

(1) Homemade MFS 600 router template Мастерская Pinterest

Making & Using Router Templates Woodsmith

How to Use Router Templates and Bearing Guides howtos DIY

Make your own adjustable DIY Router Template ! A must have Jig ! YouTube

Glue Those Together, And Sand Them Flash.

A Guide Consists Of A Round Plate That Attaches To The Router Subbase And A Tube, Or.

Web Template Routing Comes In Handy For All Kinds Of Applications, Such As Lettering, Inlays, And Shaping Identical Furniture Parts.

Web Bore A Hole At Least 1/4″ Bigger Than The Cutter Head On Your Router Bit.

Related Post: