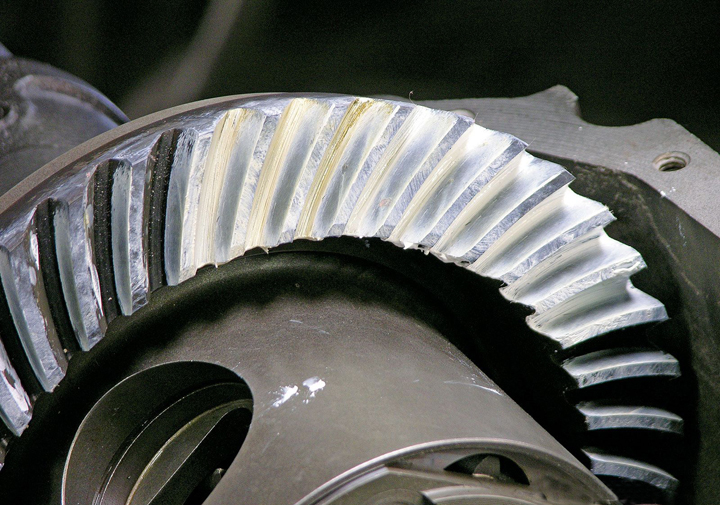

Differential Gear Pattern

Differential Gear Pattern - Use shims to move the ring gear farther from the pinion gear to increase backlash. Web the order in which adjustments are made during differential assembly and setup are: Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Increase backlash by loosening the bearing adjuster on the tooth side of the ring gear several notches. Pattern adjustment cause & effect. High contact pattern is concentrated at the crown of the drive gear tooth. The toe of the gear is the portion of the tooth surface at the end towards the center. Web two cut ring & pinion gears (face hobbed): Web ring gear and pinion tooth pattern interpretation. Pattern is running off the toe of the tooth. Web the differential carrier with the ring gear rides on bearings that also will have shims or threaded adjusters in the differential case to allow a proper mesh pattern with the pinion gear. Web how to read a differential gear pattern: There should be some clearance between the pattern and the.. Use shims to move the ring gear farther from the pinion gear to increase backlash. Loosen the opposite adjuster one notch. In this video we give a quick d. This video was created to give people a basic understanding of. Pattern adjustment cause & effect. Pattern is running off the toe of the tooth. Loosen the opposite adjuster one notch. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Pattern adjustment cause & effect. This video was created to give people a basic understanding of. High contact pattern is concentrated at the crown of the drive gear tooth. Web two cut ring & pinion gears (face hobbed): The drive pattern should be centered on the tooth. There should be some clearance between the pattern and the. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Use shims to move the ring gear farther from the pinion gear to increase backlash. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. Competition contact pattern concentrated. Web see how to set up a ring and pinion gear set. Use shims to move the ring gear closer to the pinion gear to decrease backlash. Pattern adjustment cause & effect. Our team of differential experts are available monday thru friday from 8am to 5pm. Pattern adjustment cause & effect. Use shims to move the ring gear farther from the pinion. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Use shims to move the ring gear closer to the pinion gear to decrease backlash. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Web the order in which adjustments are made during differential assembly and setup are: The images below illustrate. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. When setting the pinion position, many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier (center line of ring gear) to the face of the pinion (button). Web see. The toe of the gear is the portion of the tooth surface at the end towards the center. Loosen the opposite adjuster one notch. Use shims to move the ring gear closer to the pinion to decrease backlash. Competition contact pattern concentrated just up from the toe covering 1/3 to 1/2 of the tooth. The procedure involves changing the pinion. Competition contact pattern concentrated just up from the toe covering 1/3 to 1/2 of the tooth. Loosen the opposite adjuster one notch. Web the pattern refers to how the ring gear and pinion gears mesh. The coast pattern should be centered on the tooth, but may be slightly toward the toe. Use shims to move the ring gear closer to the pinion to decrease backlash. (see figure 3) figure 3. There should be some clearance between the pattern and the. Pattern adjustment cause & effect. Increase backlash by loosening the bearing adjuster on the tooth side of the ring gear several notches. Our team of differential experts are available monday thru friday from 8am to 5pm. Return to adjuster on the tooth side of the ring gear and tighten adjuster until it contacts the bearing cup. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. I show you how i load up the gear set to both simulate the load of the vehicle and to give you. That is, the pattern shows up slanted when the pattern is rolled with gear marking compound. This video was created to give people a basic understanding of. When setting the pinion position, many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier (center line of ring gear) to the face of the pinion (button).

Can You Install Your Own Gears at Home?

How to Set up Your Rear Gear Correctly RacingJunk News

How To Create & Read Ring Gear Patterns

How to Set up Your Rear Gear Correctly RacingJunk News

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Fig. 1 Drive Axle Gear Tooth Pattern s

Once backlash is within spec you can set the pinion depth by reading

Differential Unitec automotive engineering study 2012

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Web Pattern Is More Than 3/8” Off The Toe Of Tooth.

Web Ring Gear And Pinion Tooth Pattern Interpretation.

Once Pinion Depth Has Been Set, A Final Backlash Setting Can Be Achieved By Adjusting The Location Of The Differential And Ring Gear.

Pattern Is Running Off The Toe Of The Tooth.

Related Post: