Acceptable Gear Patterns

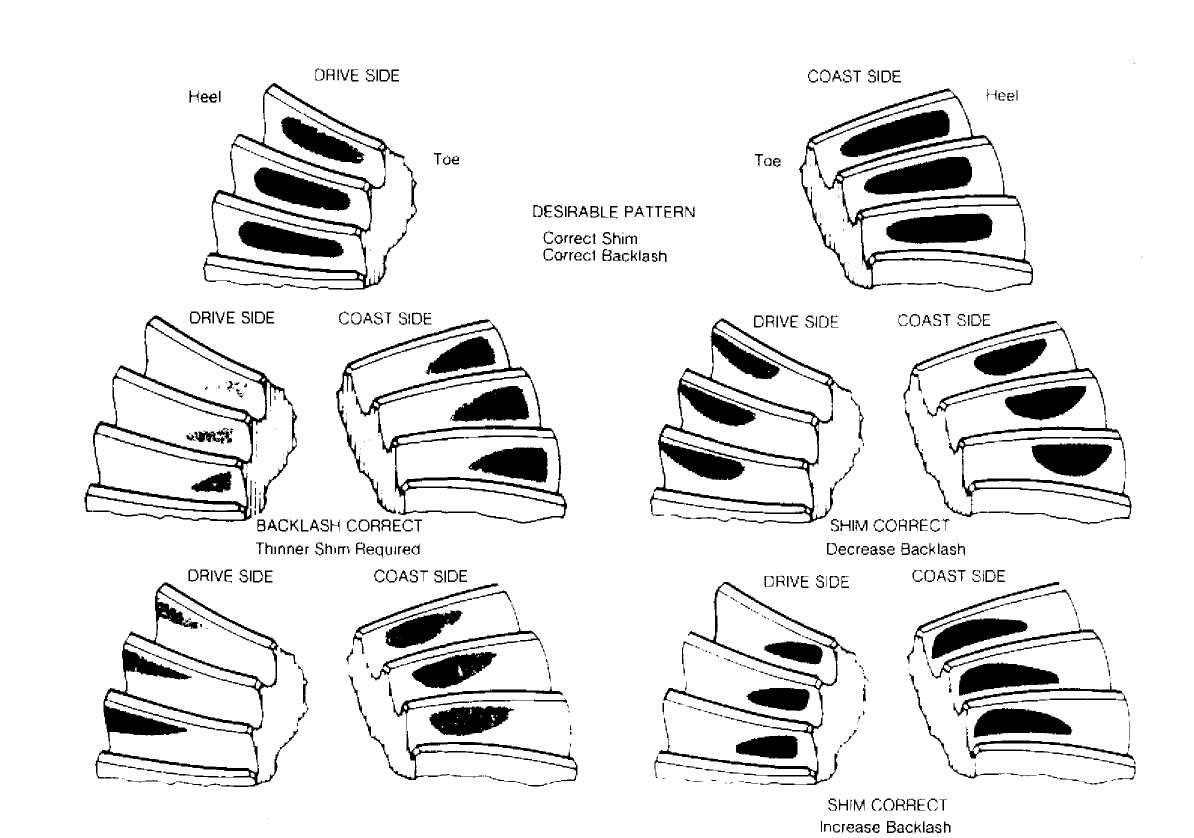

Acceptable Gear Patterns - Web 32k views 9 months ago. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 inch (.10 mm) until correct pattern has been obtained. This video was created to give people a basic understanding of how to. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 (.10 mm) until correct pattern has been obtained. Web five cut ring & pinion gears (face milled): Web every gear has a characteristic pattern. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. · 4) these are all acceptable patterns. There is one key real world element to keep in mind, and randy lyman, founder and owner of randy's. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. High contact pattern is concentrated at the crown of the drive gear tooth. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Web gear tooth patterns. Pulling off a proper differential setup comes down to precise adjustments. Web every gear has a characteristic pattern. (see figure 2) figure 2: There is one key real world element to keep in mind, and randy lyman, founder and owner of randy's. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3. Pulling off a proper differential setup comes down to precise adjustments. (see figure 2) figure 2: You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. · 4) these are all acceptable patterns. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Pulling off a proper differential setup comes down to precise adjustments. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm). Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web 32k views 9 months ago. Competition contact pattern concentrated just up from the toe covering 1/3 to 1/2 of the tooth. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Ideal contact pattern. Web we've also included the yukon chart that shows acceptable and non acceptable gear patterns. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Bearing preload, total turning preload, and. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 inch (.10 mm) until correct pattern has been obtained. Pattern should range from just clear of the toe end to about 3/8” off the toe end. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going. (see figure 2) figure 2: Web five cut ring & pinion gears (face milled): Web every gear has a characteristic pattern. · 4) these are all acceptable patterns. Web how to create & read ring gear patterns. Web every gear has a characteristic pattern. Pattern should range from just clear of the toe end to about 3/8” off the toe end. There is one key real world element to keep in mind, and randy lyman, founder and owner of randy's. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Two cut ring &. When making pinion position changes, shims should be changed in the range of.002 inch (.05 mm) to.004 inch (.10 mm) until correct pattern has been obtained. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. In general, pattern movements can be summarized this way: Ensuring peak performance and longevity. Web gear tooth patterns are harbingers… they. Web every gear has a characteristic pattern. Competition contact pattern concentrated just up from the toe covering 1/3 to 1/2 of the tooth. Two cut ring & pinion gears (face hobbed): Pulling off a proper differential setup comes down to precise adjustments. Bearing preload, total turning preload, and. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. If the gear was manufactured using the face. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. In general, pattern movements can be summarized this way: There is one key real world element to keep in mind, and randy lyman, founder and owner of randy's. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. You want to see pa!!erns that have soft edges to them. (see figure 2) figure 2: Begin by setting proper pinion. Web how to create & read ring gear patterns.

Acceptable Ring Gear Patterns Patterns Kid

Ring Gear Contact Pattern

How to Set up Your Rear Gear Correctly RacingJunk News

Gear pattern advice

How To Create & Read Ring Gear Patterns

Differential Gear Patterns

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

Acceptable Ring & Pinion Gear Patterns Auto repair, Automotive repair

Repair Guides

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Gear Tooth Patterns Are Harbingers… They Can Foretell Whether Your Ring And Pinion Gear Set Is Going To Live A Long And Prosperous Life Or If It’s Doomed To An Impending Catastrophic Failure.

The Illustrations Show Typical Patterns Only, And Explains How Patterns Shift As Gear Location Is Changed.

Web Ring Gear Contact Pattern Interpretation Of Face Hobbed (Uniform Tooth Depth) Gear Teeth.

Pulling Off A Proper Differential Setup Comes Down To Precise Adjustments.

Related Post: