Wire Drawing Machines

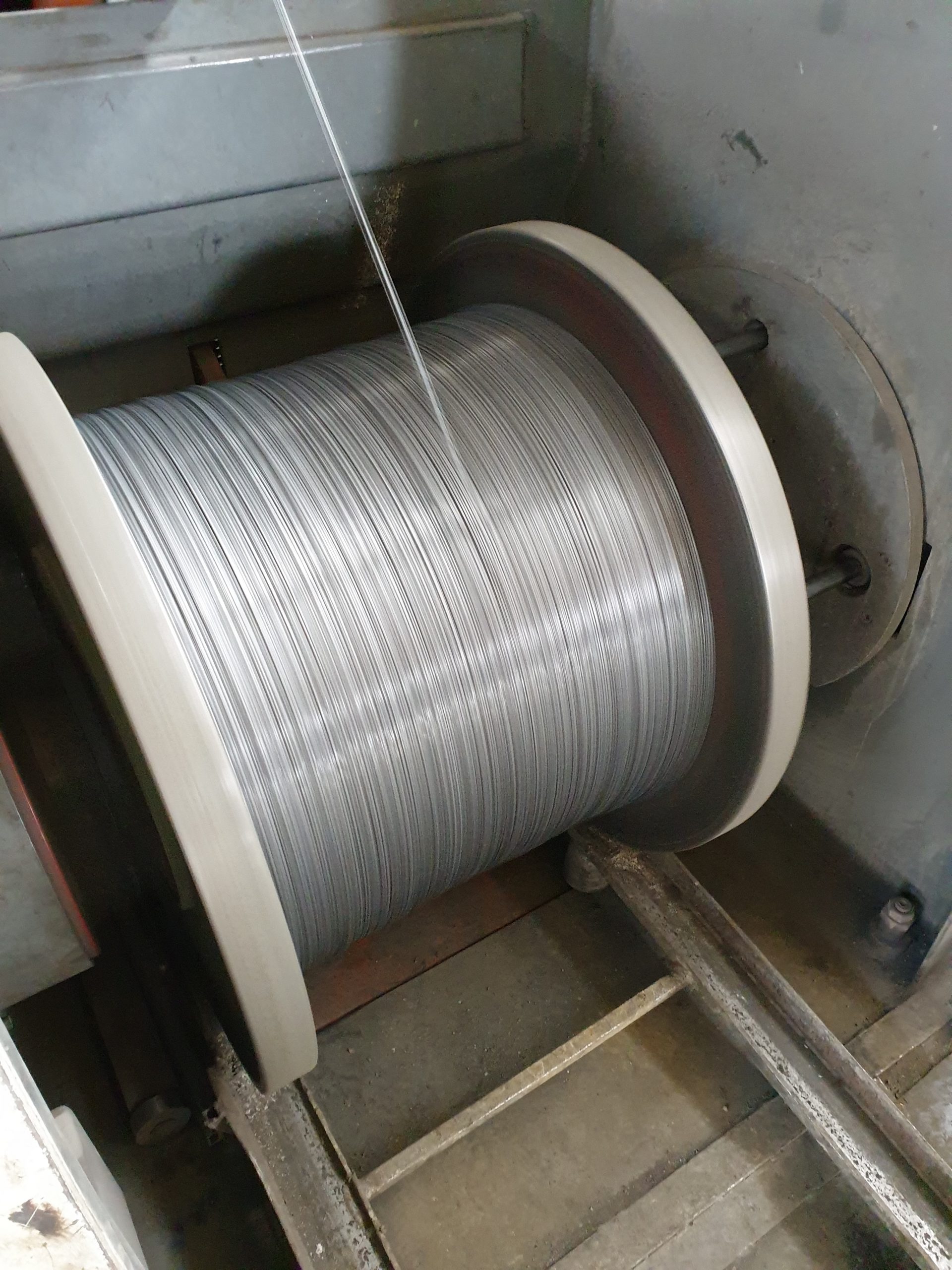

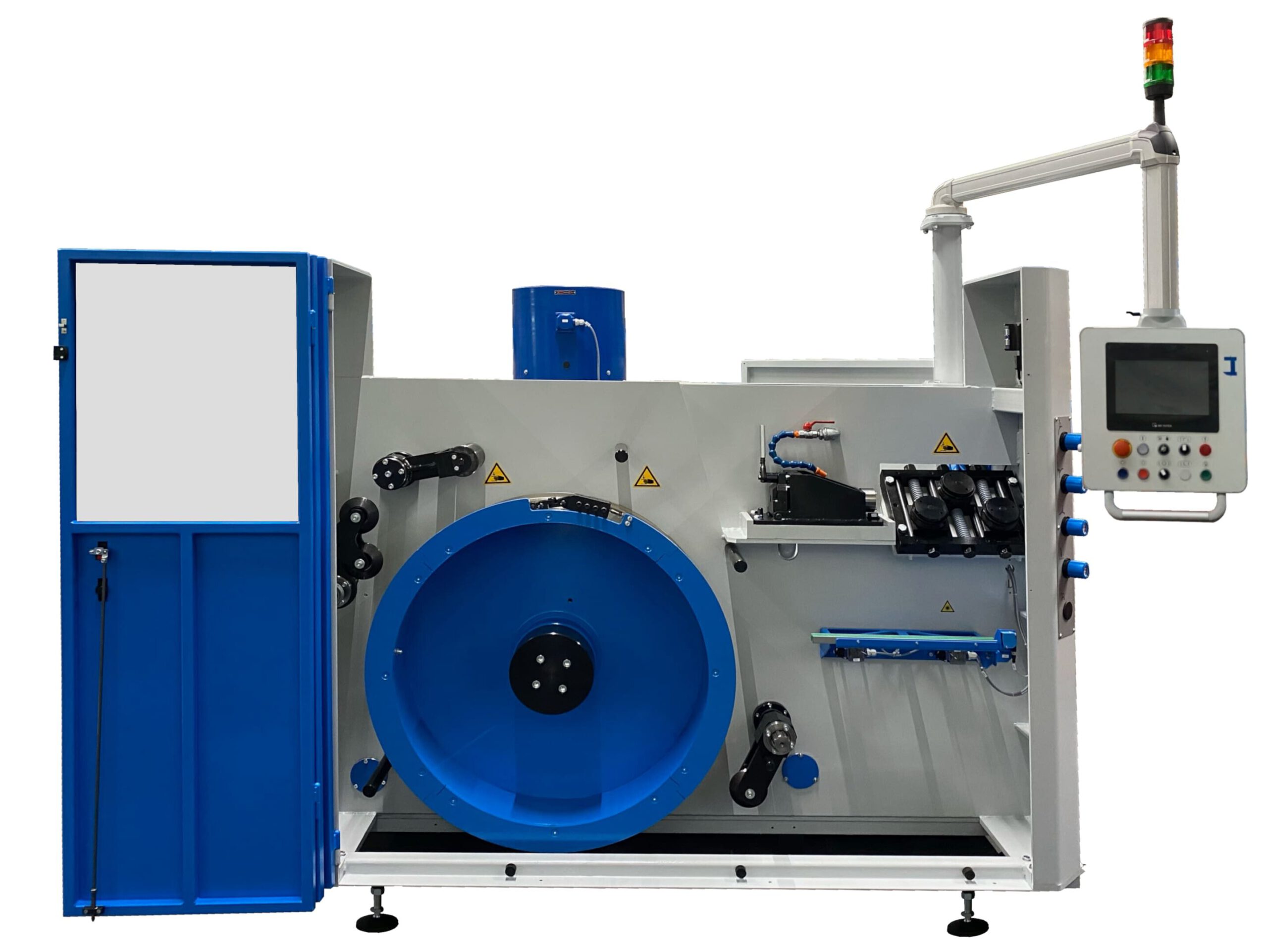

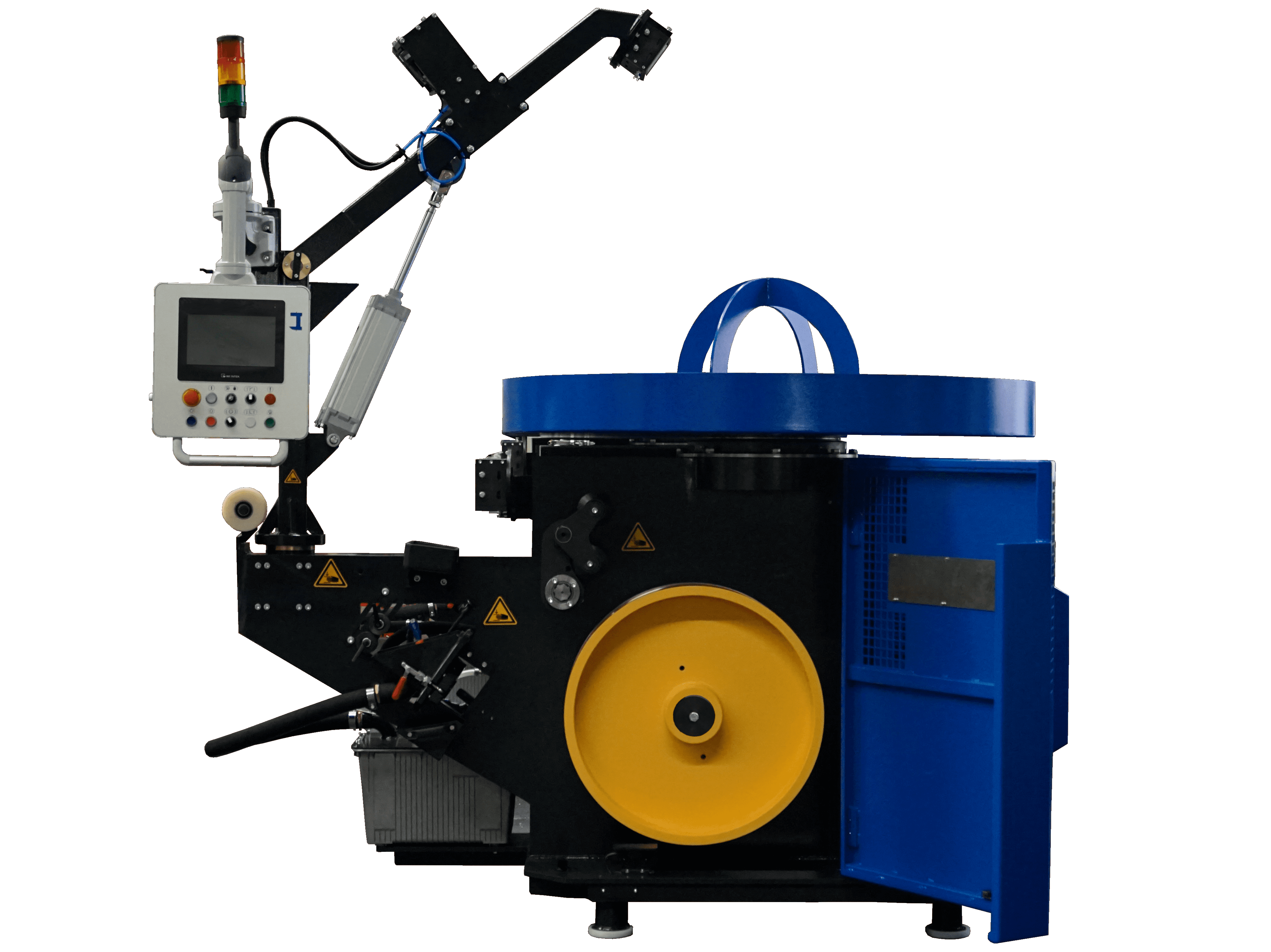

Wire Drawing Machines - The wire bending at the inlet is much less than with cone drawing machines due to the constant capstan diameter. And as a result of their highly economical design they enjoy great popularity among customers. Web as one of the world's leading manufacturers of wire drawing machines and drawing systems for the wire and cable industry, we produce braiding machines, stranding machines, stranding machines, annealing and systems for electroplating as well as turnkey projects and offer worldwide service. The amount of change in the shape of the wire is dependent on an assortment of variables including the wire material, wire temperature, amount of pulling force the wire drawing machine can produce and the. Wire drawing is a basic manufacturing process in the wire and cable industry. We do the entire design, build & test process under one roof. Web mar 20, 2024. Eurolls team meccanica is the solution you are looking for the wire drawing process, thanks to its long tradition in developing and manufacturing high performance machines that meet the customer’s needs. Setting up the wire drawing equipment. The production of fi ne wire requires machinery produced to the highest precision standards. The production of fi ne wire requires machinery produced to the highest precision standards. Web as one of the world's leading manufacturers of wire drawing machines and drawing systems for the wire and cable industry, we produce braiding machines, stranding machines, stranding machines, annealing and systems for electroplating as well as turnkey projects and offer worldwide service. Web a full. Web our robust wire drawing machines are used by virtually every major fastener and bearing manufacturer in the world. Performing the wire drawing process. Expertise, customer driven and service. Web home / products / machines for industrial wire. Eurolls team meccanica is the solution you are looking for the wire drawing process, thanks to its long tradition in developing and. In the wire industry the typical material is copper and copper alloys or aluminium and aluminium alloys. Excavators (219564) electrical & electronic. Web wire drawing is a metalworking process that shapes and reduces a wire rod by pulling it through a die that is smaller than the wire rod. Web our robust wire drawing machines are used by virtually every. Web our robust wire drawing machines are used by virtually every major fastener and bearing manufacturer in the world. In the wire industry the typical material is copper and copper alloys or aluminium and aluminium alloys. Performing the wire drawing process. They are compact and robust at the same time. Kodiak, a leading global chemical company providing specialty process fluids. In the wire industry the typical material is copper and copper alloys or aluminium and aluminium alloys. Expertise, customer driven and service. Performing the wire drawing process. We do the entire design, build & test process under one roof. Web wire drawing is a metalworking process that shapes and reduces a wire rod by pulling it through a die that. Web wire drawing, with the assistance of wire drawing machines, is essential in various cable manufacturing scenarios, including power cables, communication cables, and automotive wiring. 1 | 2 | 3. Web our robust wire drawing machines are used by virtually every major fastener and bearing manufacturer in the world. Web materials and tools required. Web the wire drawing process is. 20 | 50 | 100. Setting up the wire drawing equipment. 51 new & used wire drawer items for sale. And as a result of their highly economical design they enjoy great popularity among customers. Web our robust wire drawing machines are used by virtually every major fastener and bearing manufacturer in the world. Our technologies are state of the art in every respect. Performing the wire drawing process. The move consolidates kodiak’s foothold in the specialty chemical realm and. Web our robust wire drawing machines are used by virtually every major fastener and bearing manufacturer in the world. Web mar 20, 2024. Web as one of the world's leading manufacturers of wire drawing machines and drawing systems for the wire and cable industry, we produce braiding machines, stranding machines, stranding machines, annealing and systems for electroplating as well as turnkey projects and offer worldwide service. Eurolls team meccanica is the solution you are looking for the wire drawing process, thanks to its. 51 new & used wire drawer items for sale. For your decisive competitive edge in wire manufacturing. 1 | 2 | 3. Kodiak, a leading global chemical company providing specialty process fluids to the steel, mining, energy, water treatment and construction industries, has acquired aztech lubricants, supplier of specialty chemical products for the wire drawing industry. Our technologies are state. For the production of thin wires, e.g. Web wire drawing, with the assistance of wire drawing machines, is essential in various cable manufacturing scenarios, including power cables, communication cables, and automotive wiring. Kodiak, a leading global chemical company providing specialty process fluids to the steel, mining, energy, water treatment and construction industries, has acquired aztech lubricants, supplier of specialty chemical products for the wire drawing industry. 1 | 2 | 3. Performing the wire drawing process. From copper, aluminum or other alloys, the wire passes through several drawing stages, drawing tools, and other processes such as. Web mar 20, 2024. They guarantee that the wire has the right technological specifications, they improve both dimensional accuracy and surface quality. The amount of change in the shape of the wire is dependent on an assortment of variables including the wire material, wire temperature, amount of pulling force the wire drawing machine can produce and the. Selecting the appropriate wire material. The production of fi ne wire requires machinery produced to the highest precision standards. Web wire drawing is a metalworking process that shapes and reduces a wire rod by pulling it through a die that is smaller than the wire rod. Web as one of the world's leading manufacturers of wire drawing machines and drawing systems for the wire and cable industry, we produce braiding machines, stranding machines, stranding machines, annealing and systems for electroplating as well as turnkey projects and offer worldwide service. Web due to the intelligent interaction of scalable drive and controller technology and comprehensive standard libraries, you benefit from efficient engineering and high cost effectiveness. They are compact and robust at the same time. 20.2.2 electronically driven intermediate wire drawing machine.

Wire drawing machines

Wire Drawing Machine Tips and Tricks from A to Z by WESPEC

Bet Wire Drawing Machine, 230 V, Capacity 500 Kg Within 12 Hours, ID

fine(work) live video of wire drawing machine YouTube

High Speed M S Wire Drawing Machine Buy High Speed Straight Line M S

Wire drawing machines Jankowski GmbH & Co. KG

Horizontal Type Fine Copper Wire Drawing Machine With Low Price Buy

Wire drawing machines Schmidt Maschinenbau GmbH

Wire drawing machines

Wire drawing machines Jankowski GmbH & Co. KG

Schumag Equipment & More | Machinio.

Web Materials And Tools Required.

The Move Consolidates Kodiak’s Foothold In The Specialty Chemical Realm And.

Samp Authorized Service And Spare Parts Ensure That Your Machines Are Producing Reliably Over An Extended Lifetime.

Related Post: