Welding Weaving Patterns

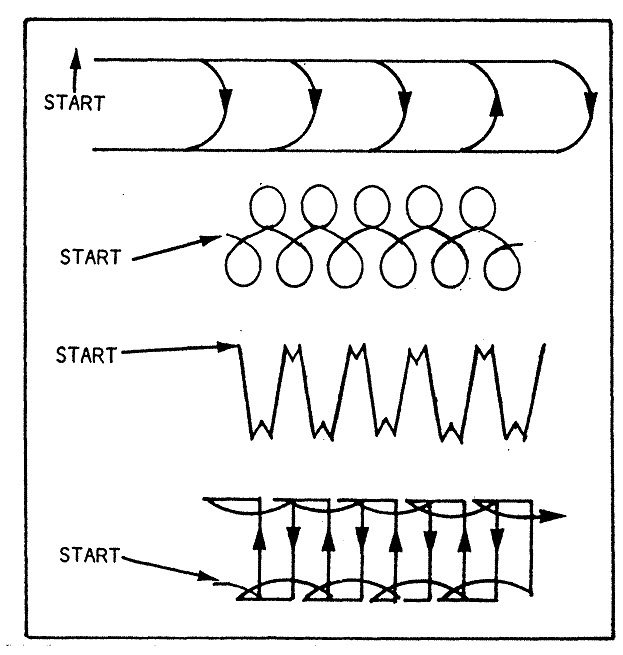

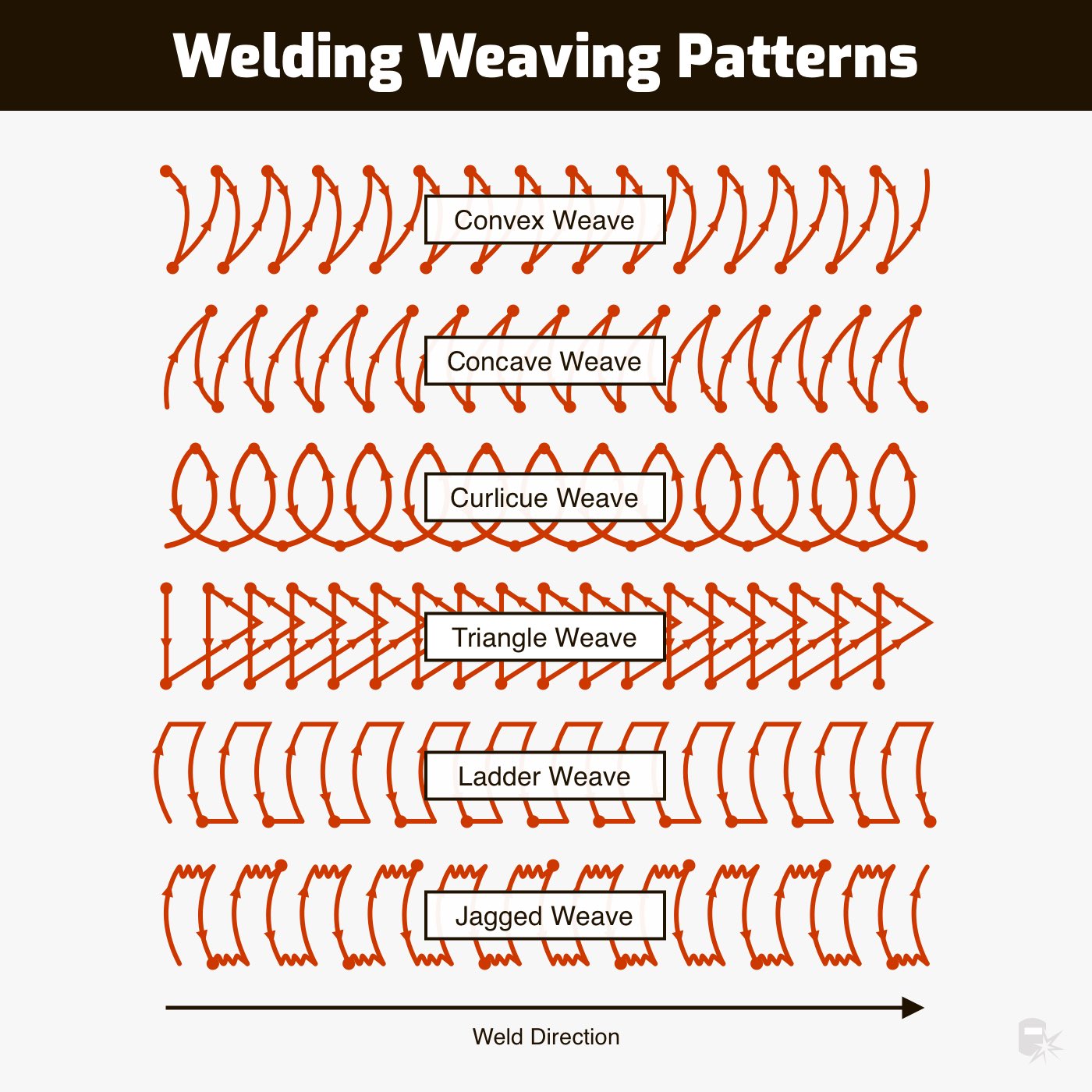

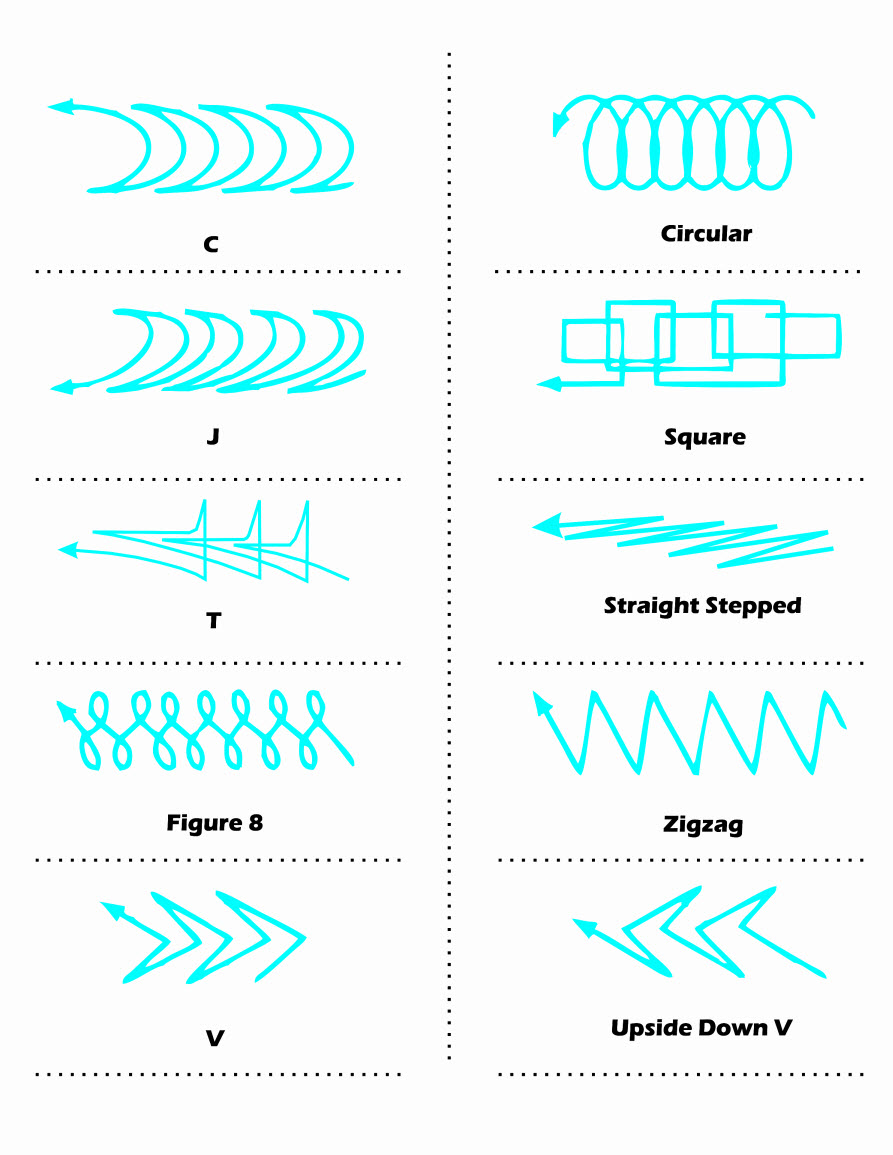

Welding Weaving Patterns - Like a shipyard, some places do not allow you to use a weaving pattern, but in general, you should use a weaving pattern when you are not working on a critical joint. The more movement you have in your weld pattern, the higher the degree of difficulty will be. Each pattern offers unique benefits and is used for specific welding applications. You use this motion to make cover welds over stringer beads (multipass welding). These patterns significantly impact the final weld bead's shape, size, and penetration depth. This motion allows you to make cover welds over stringer beads,. Walking the cup and freehand. Just as a note in most shipyards weaving is not allowed. Most people assume that all weaved tig welds are “walked.”. Web when you are welding large joints, you can use a weaving technique. We’ll hit on the latter in a bit, but right now let’s focus on the former. Walking the cup and freehand. Web the weaving volume is usually limited to 2.5 to 3 times the electrode core diameter. There are several benefits of employing weaving patterns in. You use this motion to make cover welds over stringer beads (multipass welding). Properly executed weave patterns ensure uniform heat distribution, prevent overheating and enhance the weld's structural. In many instances, you'll just need a straight bead. This motion allows you to make cover welds over stringer beads,. There are many things to remember when setting up your mig welding machine. Web weaving in the overhead position can be challenging since gravity tends. You will make a weaving pattern in order to cover a larger area. Web wave bead patterns. Weave bead welding is exactly as it sounds; A short stickout of no more than 3/8″ is also important for deep penetration. Weaves are good for big joints that have no distortion issues. The weaving welding technique involves making a series of overlapping circles with the electrode as you progress along the stable full arc length of the weld joint. You will make a weaving pattern in order to cover a larger area. It is achieved by offsetting the motion of the weld arc as it moves along the taught weld path. Weaves. However, in some places, weaving is forbidden when welding. If you want to learn more. Weaving increases the weakening of the weld metal with the original metal and should be minimized when welding alloy steels. Web wave bead patterns. Most people assume that all weaved tig welds are “walked.”. Figure 12 presents the geometry of the plates, with the corresponding mesh used on the fem simulation, which is composed. But welders learn to do it since weaving saves time compared to running multiple stringer beads. The four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and. There are many things to remember when setting up your mig welding machine. Web there are basically two ways to weave a tig weld: Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. Web wave bead patterns. A stringer bead is a straightforward welding pattern where the weld is made in. Web as an amazon associate i earn from qualifying purchases. However, in some places, weaving is forbidden when welding. Most people assume that all weaved tig welds are “walked.”. Web a weave bead is a type of weld bead, typically used when time is limited and wider area needs to be welded. Web mig welding, one of the most straightforward. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. That happens because the fast. These patterns significantly impact the final weld bead's shape, size, and penetration. But welders learn to do it since weaving saves time compared to running multiple stringer beads. Web when you are welding large joints, you can use a weaving technique. This pattern is commonly used for. Web weaving welding technique pattern. Properly executed weave patterns ensure uniform heat distribution, prevent overheating and enhance the weld's structural. Web wave bead patterns. [welder101] whip motion (for stick) Like a shipyard, some places do not allow you to use a weaving pattern, but in general, you should use a weaving pattern when you are not working on a critical joint. This creates an even and consistent heat distribution across the tight arc length of the weld area, which results in a strong. Web a weave bead is a type of weld bead, typically used when time is limited and wider area needs to be welded. Weaving is an arc welding technique which allows for filling a wide, flat joint or welding thick metals by adding a weave pattern to cover a larger surface area. To create a wider bead on thicker material, manipulate the electrode from side to side, creating a continuous series of partially overlapping circles in a. You use this motion to make cover welds over stringer beads (multipass welding). The weave weld pattern produces a wide and convex bead that has moderate penetration and slow travel speed. Web mig welding weave patterns include the stringer (straight line), crescent, zigzag, and overlapping weaves. Most people assume that all weaved tig welds are “walked.”. Weaves are good for big joints that have no distortion issues. These patterns significantly impact the final weld bead's shape, size, and penetration depth. A stringer bead is a straightforward welding pattern where the weld is made in a straight line without any weaving motion. We will explain each of these weaving techniques in this. You will make a weaving pattern in order to cover a larger area.

Weaving in welding A comprehensive guide to weave patterns

Tig weave Welding art, Metal welding, Welding and fabrication

DIFFERENT TYPES OF WEAVING USED IN THE PROCESS OF WELDING Nikit

Pin on tig welding

What weave pattern you like most? Diy welding, Welding, Welding and

Welding Techniques

Welding Beads What Are They? & Different Types

How do you get those weaved welds?

Weaving in welding A comprehensive guide to weave patterns

DIFFERENT TYPES OF WEAVING USED IN THE PROCESS OF WELDING Nikit

Web On Material 1/4 Inch And Thinner, You Don't Typically Need To Weave Weaving The Electrode Because The Bead Will Be Wider Than Necessary.

Each Pattern Offers Unique Benefits And Is Used For Specific Welding Applications.

This Motion Allows You To Make Cover Welds Over Stringer Beads,.

Weave Bead Welding Is Exactly As It Sounds;

Related Post: