Types Of Calendering

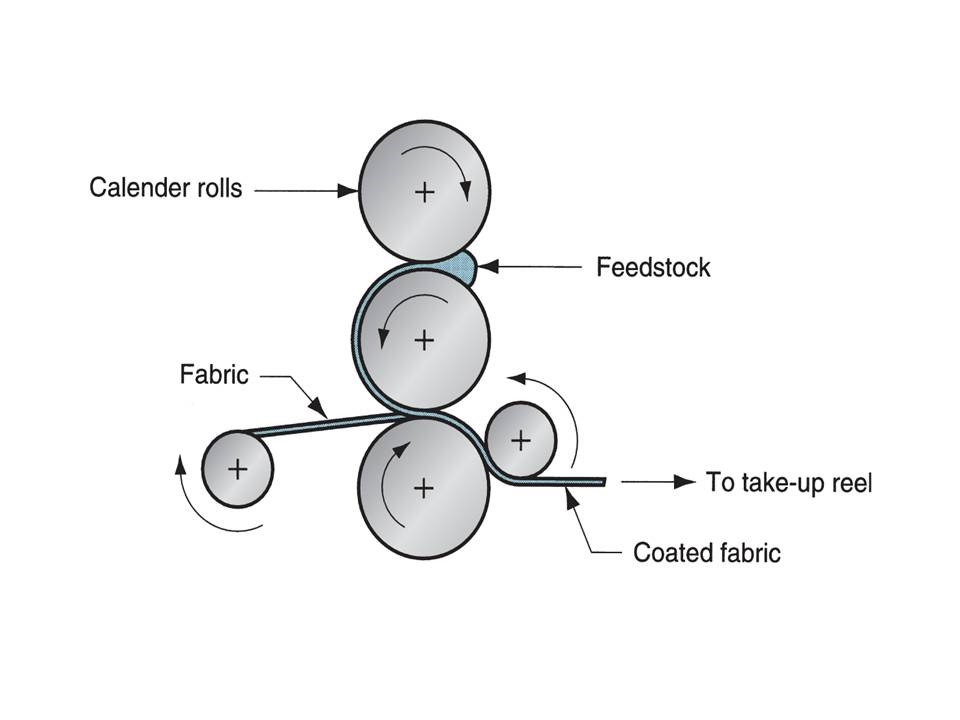

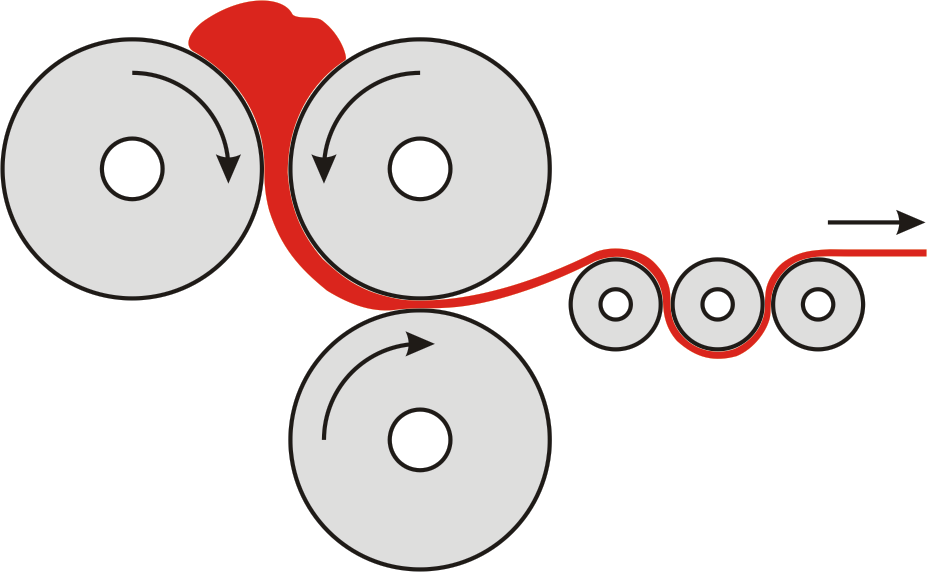

Types Of Calendering - Web there are various types of calendaring. Web parameters of calendering finishing process: Web types of calendaring machines: The calender is also an important processing machine in the rubber industries, especially in the manufacture of tires, where it is used for the inner layer and fabric layer. Web the calendering process usually involves using four or more pairs of rollers that gradually reduce the plastic thickness, polish the surface, add a texture or emboss a pattern into. The types of calendaring machines getting used in the industry are given below: Web developers polymer product manufacturing steps calendering is one of the ways you can process the polymer in the manufacture of polymer products: Web by salma hasin with the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Calendering by definition is a mechanical leveling and segmenting process for “finishing” fabrics or webs to obtain or to. Web roll bending energy efficiency references how it works the calender concept is fairly easy to understand. • plasticating unit • calender • cooling unit • accumulator Web 10 calendering overview calendering is essentially extruding a plastic material between successive pairs of corotating, parallel rolls to form a film or sheet. Web developers polymer product manufacturing steps calendering is one of the ways you can process the polymer in the manufacture of polymer products: In hot calendering,. On the basis of quality. These are given by mechanical arrangements. Web this particular type of calendering process allows engraving a simple pattern on the fabric. Web types of calendaring machines: Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. In friction calender, plain calender rollers are used with hot metallic roller in. Web there are several different types of calendering, each with its own unique characteristics and applications, including hot calendering, emboss calendering, and. On the basis of quality. Four basic calender arrangements [15,16]. This simultaneous action is called. Web this particular type of calendering process allows engraving a simple pattern on the fabric. The basic idea of the machine is that squishes a heat softened. Web calendering machine for textile: This simultaneous action is called. In hot calendering, fabric passes through. On the basis of quality. Web wet process engineering october 9, 2021 maksudur rahman 0 calendering | factors effecting calendering | calendering machine construction 432 more now. Web the calendering process usually involves using four or more pairs of rollers that gradually reduce the plastic thickness, polish the surface, add a texture or emboss a pattern into. Four basic calender. This simultaneous action is called. The calender is also an important processing machine in the rubber industries, especially in the manufacture of tires, where it is used for the inner layer and fabric layer. These are given by mechanical arrangements. Web by salma hasin with the simultaneous action of temperature, force and moisture, the surface of the textile substrate are. This simultaneous action is called. On the basis of quality. Web there are several different types of calendering, each with its own unique characteristics and applications, including hot calendering, emboss calendering, and. Web by salma hasin with the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. In hot calendering, fabric passes through. Some of the parameters affecting the calendering process are as follows: These are given by mechanical arrangements. This simultaneous action is called. Web by salma hasin with the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Web 10 calendering overview calendering is essentially extruding a plastic material between successive pairs of corotating, parallel. Some of the parameters affecting the calendering process are as follows: Web calendering machine for textile: This simultaneous action is called. To produce a pattern in relief by passing fabric through a calendar. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web calendering can be classified into various types based on the desired effect and the characteristics of the fabric: Web calendering machine for textile: The calender is also an important processing machine in the rubber industries, especially in the manufacture of tires, where it is used for the inner layer and fabric layer. Drying cylinders or stenter can be used. Web calendering | factors effecting calendering | calendering machine construction calendering with the simultaneous action of temperature, force and. Web types of textile finishing: These are given by mechanical arrangements. To produce a pattern in relief by passing fabric through a calendar. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. This simultaneous action is called. Web developers polymer product manufacturing steps calendering is one of the ways you can process the polymer in the manufacture of polymer products: The basic idea of the machine is that squishes a heat softened. Web calendering machine for textile: Four basic calender arrangements [15,16]. Web there are several different types of calendering, each with its own unique characteristics and applications, including hot calendering, emboss calendering, and. The calender is also an important processing machine in the rubber industries, especially in the manufacture of tires, where it is used for the inner layer and fabric layer. • plasticating unit • calender • cooling unit • accumulator Web the calendering process usually involves using four or more pairs of rollers that gradually reduce the plastic thickness, polish the surface, add a texture or emboss a pattern into. Web roll bending energy efficiency references how it works the calender concept is fairly easy to understand. Some of the parameters affecting the calendering process are as follows:

Calendar Design Service, Professional Calendar Designing Services

Different Types Of Calendars Used Around The World, First Calendar In The World

24 Stunning Calendar Designs for Inspiration (Updated!) PrintRunner Blog

6 Types Of Calendering Process In Textile Textile Property

24 Stunning Calendar Designs for Inspiration (Updated!) PrintRunner Blog

24 Stunning Calendar Designs for Inspiration (Updated!) PrintRunner Blog

10 Facts About Calendering in Textile! Textile Property

6 Types Of Calendering Process In Textile Textile Property

24 Stunning Calendar Designs for Inspiration (Updated!) PrintRunner Blog

24 Stunning Calendar Designs for Inspiration (Updated!) PrintRunner Blog

The Types Of Calendaring Machines Getting Used In The Industry Are Given Below:

Web Parameters Of Calendering Finishing Process:

Drying Cylinders Or Stenter Can Be Used To Provide A Series Of.

Web By Salma Hasin With The Simultaneous Action Of Temperature, Force And Moisture, The Surface Of The Textile Substrate Are Modified.

Related Post: