Twisted Damascus Pattern

Twisted Damascus Pattern - This is an in depth tutorial on how to make a twist damascus pattern. Web the topic of the month for july 2016 is, damascus pattern development. Then i combined the billets together with 3 pieces of 15n20 between each layer. Web types of damascus steel patterns. This is an interesting damascus pattern with lots of nuances so c. More specifically, advanced damascus pattern development. He bird’s mouthed the blade tip and rewelded it back together to create flowing outer bars. Web 🔥🔥🔥🔥🔥🔥my name is kyle royer, i am a master bladesmith. The bar is heated until it is close to welding temperature, and then twisted. About ten to fifteen small steel blocks are continuously hammered or pressed and cooled. Web after this, the bar is welded back together, which results in the feather damascus pattern. Web making twisted w damascus steel for a beautiful set of five knives. Forging damascus is one of my favorites things!watch this full build 👇🏼episode: Web both at 14 layers were drawn to 12 and cut in half to 6 lengths giving me 4. Web making twisted w damascus steel for a beautiful set of five knives. This is an interesting damascus pattern with lots of nuances so c. Web 25% off original merch using code: Web a twisted damascus is a knife that has been crafted from two different types of steel. Web gentle, elegant, and striking. Pull the billet and immediately brush it off with a wire brush then set the welds by gently hammering from end to end. There are multiple variants of twist patterns in damascus steel. The twisted damascus pattern is timeless and easy to achieve. The cruforge v etches darkly, and its wear resistance and high working hardness make it ideal for. More specifically, advanced damascus pattern development. Evoking the robustness of a steel cable, this pattern is all about raw power and resilience. Web a twisted damascus is a knife that has been crafted from two different types of steel. The two steel sheets are forge welded together to create a twisted pattern on the blade. Some of the most common. Pull the billet and immediately brush it off with a wire brush then set the welds by gently hammering from end to end. Web gentle, elegant, and striking. Keep welding until the billet looses its. The steel brick is then placed back in the forge. This rod is then twisted which is what creates that amazing twist pattern. Web types of damascus steel patterns. These are the most basic damascus patterns and the same patterning techniques, and several others, are. There are multiple variants of twist patterns in damascus steel. The result is a spiral pattern that resembles a twisted rope. There are many different types of damascus steel patterns, each with its own unique characteristics. Web a twisted damascus is a knife that has been crafted from two different types of steel. Web like the names of most damascus steel patterns, this category describes that the pattern looks like. About ten to fifteen small steel blocks are continuously hammered or pressed and cooled. Forge welded giving me a total of 59 layers. Drawn and folded. This rod is then twisted which is what creates that amazing twist pattern. More specifically, advanced damascus pattern development. Web 25% off original merch using code: These are the most basic damascus patterns and the same patterning techniques, and several others, are. Second, as the steel is heated and folded, the gradient of twist needs to be decided. There are multiple variants of twist patterns in damascus steel. Web the twisted damascus pattern follows a very simple process that produces various outcomes. Most damascus smiths know how to create simple damascus patterns. Forging damascus is one of my favorites things!watch this full build 👇🏼episode: Second, as the steel is heated and folded, the gradient of twist needs to. This pattern is created by twisting the billet of steel before it is forged. This rod is then twisted which is what creates that amazing twist pattern. A bar of the desired number of layers is forged into a square and the corners are forged down slightly. Web like the names of most damascus steel patterns, this category describes that. I am teaching bob earhar. A bar of the desired number of layers is forged into a square and the corners are forged down slightly. The twisted damascus pattern is timeless and easy to achieve. He bird’s mouthed the blade tip and rewelded it back together to create flowing outer bars. The cruforge v etches darkly, and its wear resistance and high working hardness make it ideal for culinary knives. In this video you can see the hand twisting option using a pipe wrench. The result is a spiral pattern that resembles a twisted rope. First, the metal worker needs to decide how many layers they want to use. About ten to fifteen small steel blocks are continuously hammered or pressed and cooled. Some of the most common types include: Web 🔥🔥🔥🔥🔥🔥my name is kyle royer, i am a master bladesmith. To create the pattern, a blacksmith needs a minimum of four finished damascus billet rods. Web types of damascus steel patterns. Web both at 14 layers were drawn to 12 and cut in half to 6 lengths giving me 4 total lengths. Web the raindrop damascus pattern adds interest and an artistic flare to a variety of projects. Forging damascus is one of my favorites things!watch this full build 👇🏼episode:

Custom Handmade Twist Damascus Steel Subhilt Fighter Bowie Knife from

Custom Handmade Damascus steel Twist pattern shef for Etsy

Medium Kitchen Knife Twisted Damascus Owen Bush Bushfire

In Depth Tutorial on How to Make a Twist Damascus Pattern YouTube

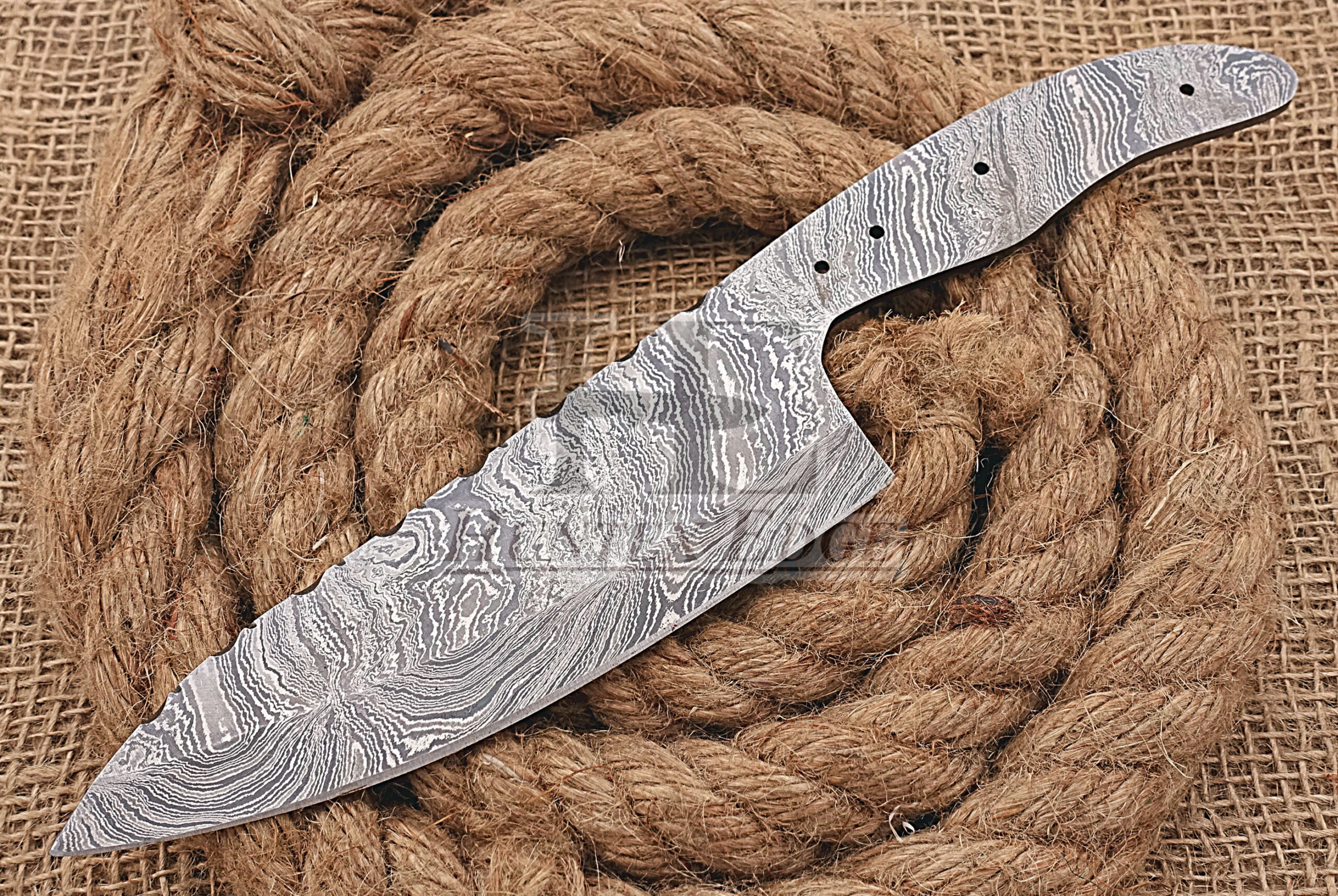

HUNTEX Brand New Custom Handmade Twist Pattern Damascus 254 mm Long DIY

Hand Full Damascus Steel Blade Twist Pattern 8 inches

As Twisted Pattern Damascus Steel Owen Bush Bushfire

Twist Damascus Pattern Welded Blade Basics American Bladesmith

As Twisted Pattern Damascus Steel Owen Bush Bushfire

Damascus Patterns knives, Metal working, Blacksmithing knives

Then I Combined The Billets Together With 3 Pieces Of 15N20 Between Each Layer.

Second, As The Steel Is Heated And Folded, The Gradient Of Twist Needs To Be Decided.

Forge Welded Giving Me A Total Of 59 Layers.

The Two Steel Sheets Are Forge Welded Together To Create A Twisted Pattern On The Blade.

Related Post: