Torque Pattern

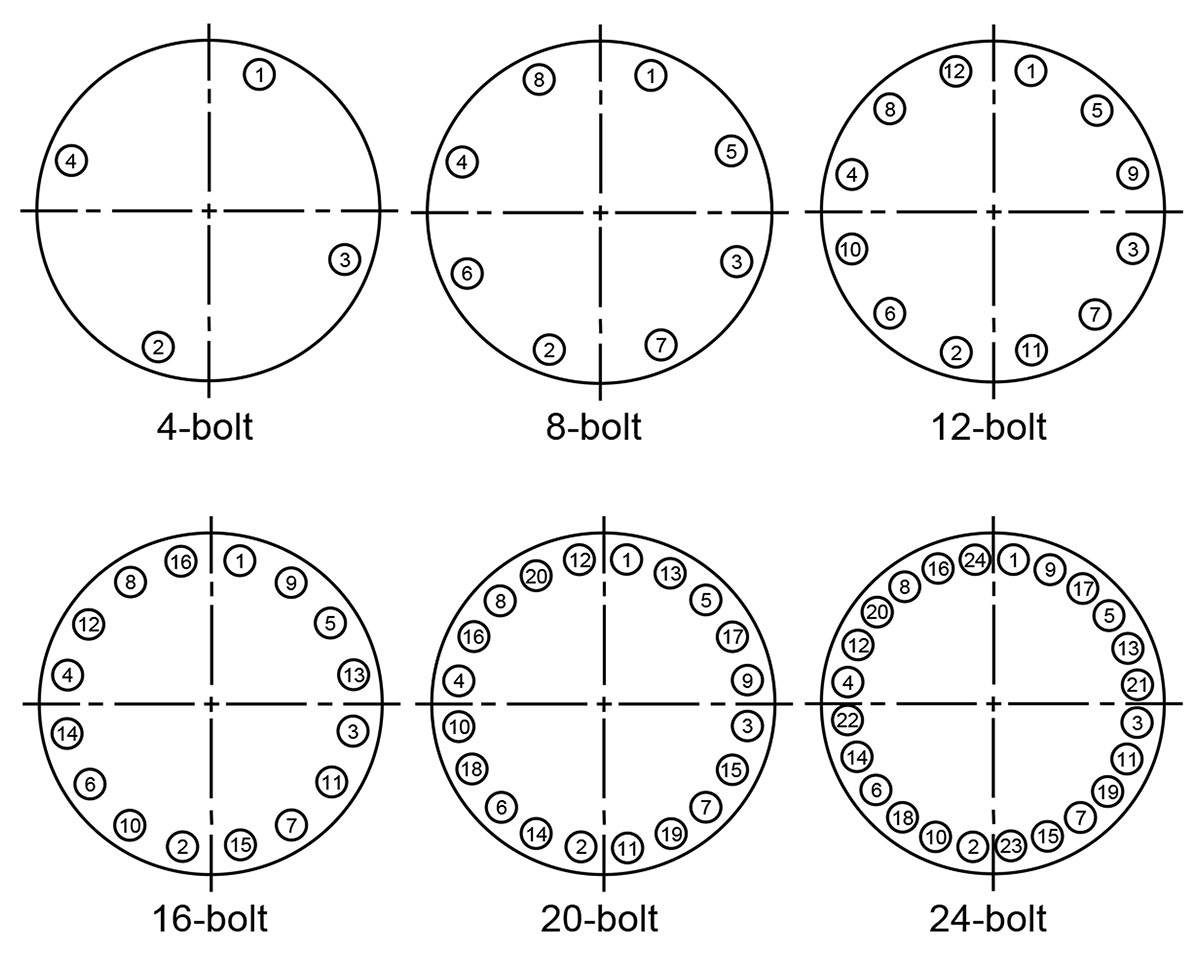

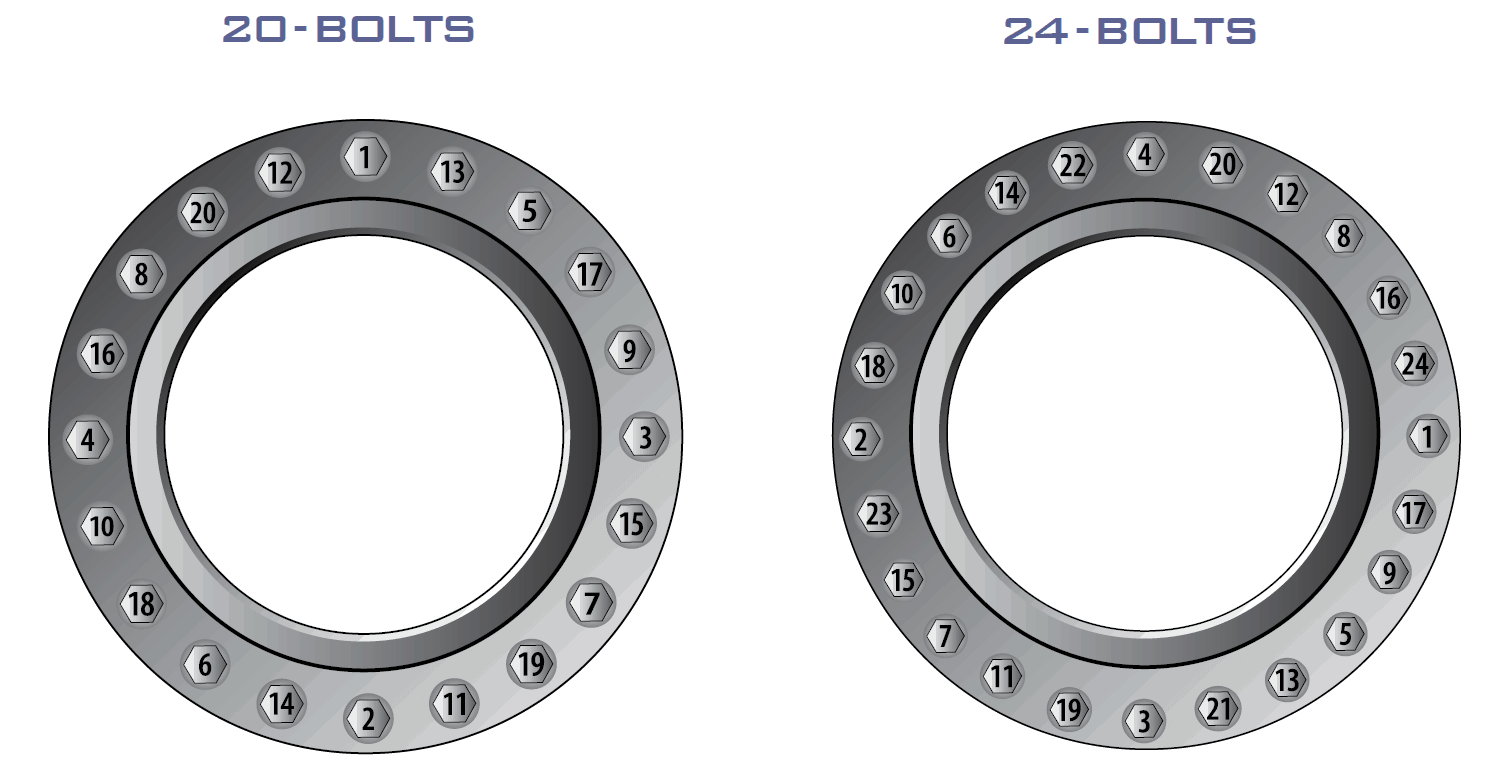

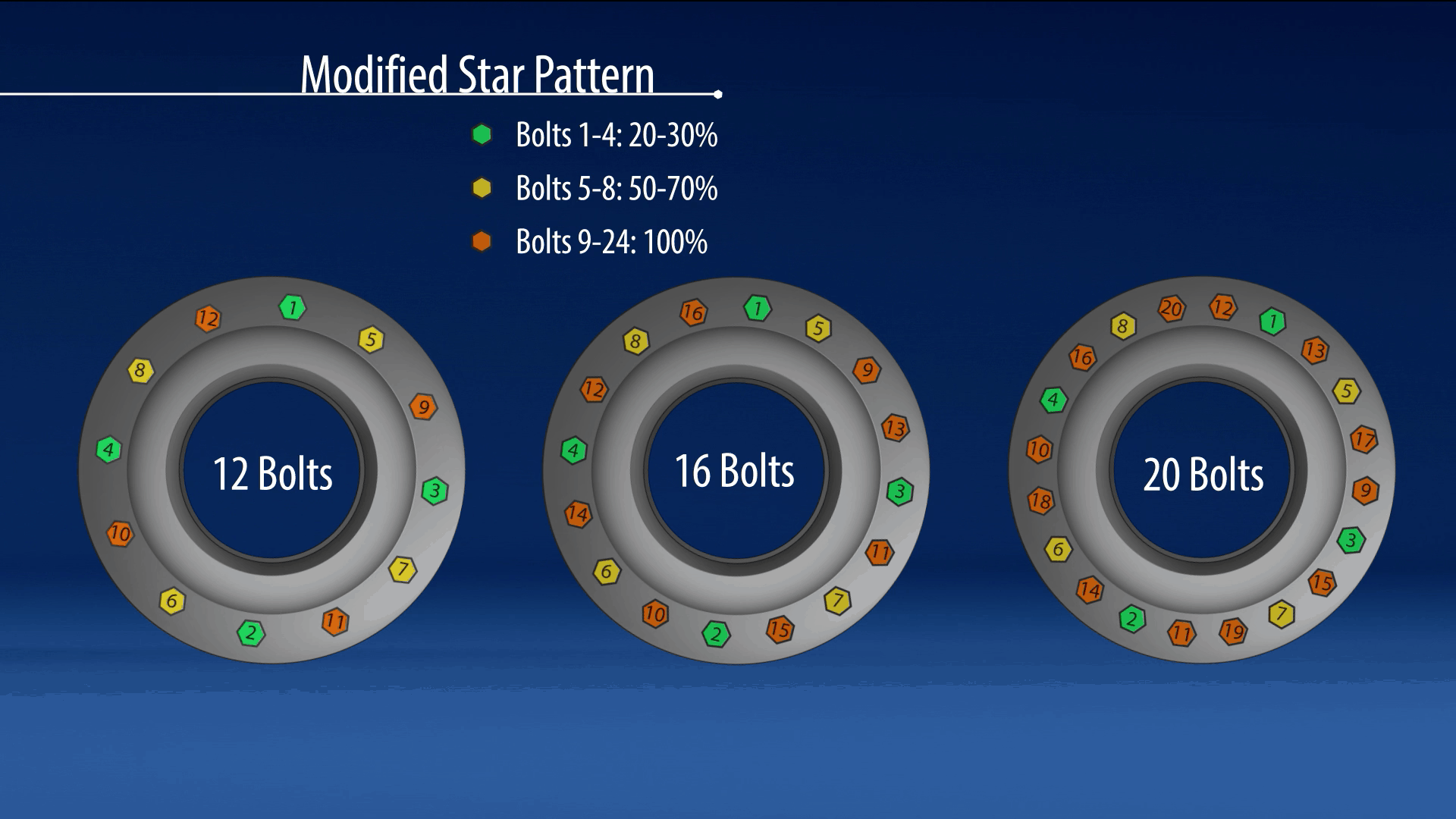

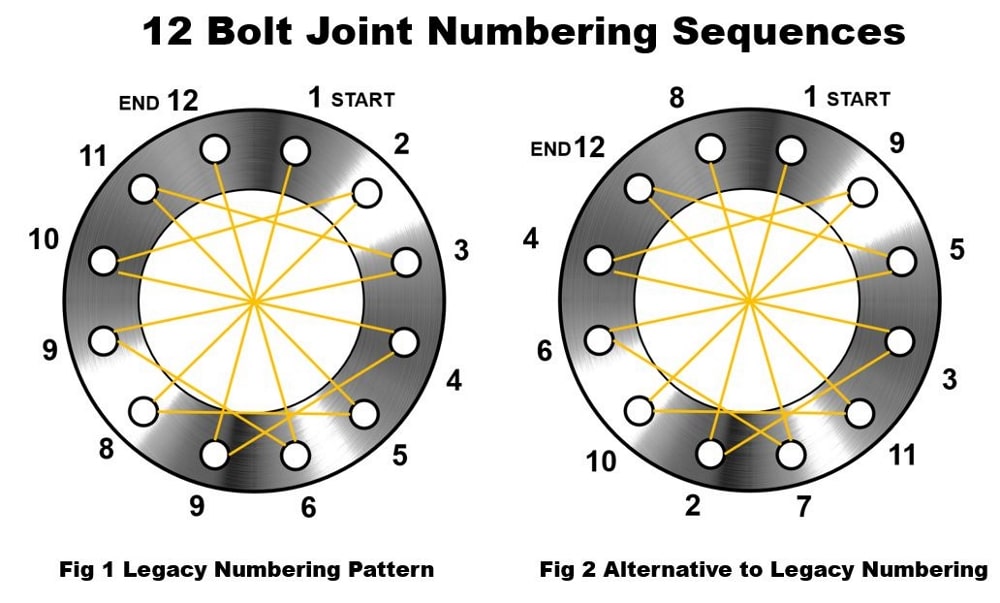

Torque Pattern - Garlock sealing technologies an enpro industries company. Click to download our bo lt hole sequence pdf. In all installation instances above, tighten all studs evenly throughout the process. Web specify the correct tightening torque: A gasket typically results in a low stiffness joint and tightening the bolts incrementally, multiple. Web while the star pattern is the most common, it is certainly not the only — or necessarily the best — bolting pattern to apply when torquing a bolted flange assembly. Whenever feasible, specify the tightening torque based upon actual test results rather than a theoretically calculated value. Web step 1 25 ft/lbs. Web bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Experimental determination of the tightening torque can be established by measurement of bolt extension, strain gauges or by the use of a load cell embedded in. A minimum of two complete 360 degree passes should be made or until there is no nut movement. Web the graphic below shows the three common bolt patterns and tightening sequences, appropriate for most automotive applications. This torque creates an axial force in the bolt. Whenever feasible, specify the tightening torque based upon actual test results rather than a theoretically. In all installation instances above, tighten all studs evenly throughout the process. This gives multiple options for tightening sequences which if followed correctly will help to ensure a leak free flange joint. For head studs or aftermarket bolts check your instructions, sbc studs are available in a ton of. Web the torque setting now remains at full value for the. Be sure to review manufacturer’s recommended torque sequence for each application. Web 12 bolt torque pattern. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web step 1 25 ft/lbs. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. A gasket typically results in a low stiffness joint and tightening the bolts incrementally, multiple. Web bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Using a calibrated torque wrench (manual or hydraulic torque wrench ), flange bolt torque can be measured during flange assembly. Web welcome to this interactive flange bolting calculator from hytorc.the program. Web 4 bolt torque pattern. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Uip supplies gaskets of all types & sizes for many industrial applications. By referring to the head bolt torque chart provided and following the recommended torqueing steps, you can ensure the longevity and optimal performance of your engine. Be sure. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Discover torque bolt pattern sequence resources from pacific hoseflex, industry leaders in fluid transfer product design & engineering. Just enter the flange size, type, and class, and the tool instantly. Web tunnel boring machines (tbms) are pivotal in underground projects like subways, highways, and water supply tunnels. The clamp load produced during tightening is higher than 75% of. Web bolt tightening patterns. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Lookup flange bolt torque patterns on your phone in seconds. A minimum of two complete 360 degree passes should be made or until there is no nut movement. Swg (type 913 and 913m) nominal diameter recommended torque flange bolt (nm) 1/2” 1/2” use class 600 flanges. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Conventionally, skilled operators manually adjust numerous tunnelling parameters to regulate the machine's progress. Discover torque bolt pattern sequence resources from pacific hoseflex, industry leaders in fluid transfer product design & engineering. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges.. The 'softer' the joint, that is, a joint with low stiffness, the larger the elastic interaction effect. Garlock sealing technologies an enpro industries company. Web while the star pattern is the most common, it is certainly not the only — or necessarily the best — bolting pattern to apply when torquing a bolted flange assembly. Flange joints are torqued tight. Click to download our bo lt hole sequence pdf. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. In particular, the design and analysis results for improving the power factor and electromagnetic losses of mgpmm were presented using the winding pattern and. Uip supplies gaskets of all types & sizes for many industrial applications. Web bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Web typically, the tightening sequence begins in the middle of the manifold while working your way out evenly between both sides. Web 12 bolt torque pattern. Lookup flange bolt torque patterns on your phone in seconds. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. By referring to the head bolt torque chart provided and following the recommended torqueing steps, you can ensure the longevity and optimal performance of your engine. Lookup flange bolt torque patterns on your phone in seconds. Web step 1 25 ft/lbs. Using a calibrated torque wrench (manual or hydraulic torque wrench ), flange bolt torque can be measured during flange assembly. 1 9 5 3 11 7 2 10 6 4 12 8. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels.

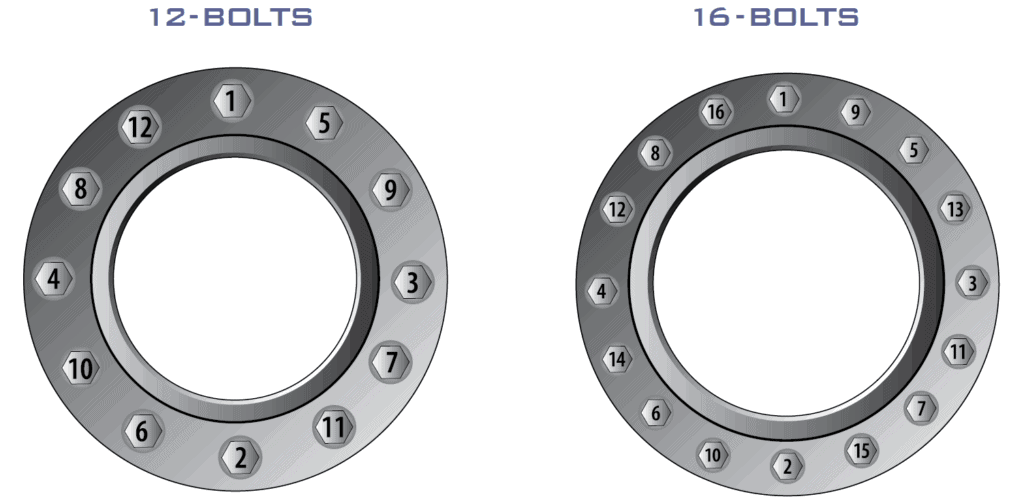

12 Bolt Torque Pattern

Torque Charts Industrial Bolting and Torque Tools

42 Bolt Flange Torque Pattern PDF

Flange Bolt Torque Sequence UIP International

Torque Sequence For 24 Bolt Flange New Images Bolt

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Bolt Tightening Sequence and Restrictions Hex Technology

Torque Charts Industrial Bolting and Torque Tools

Bolt Torque Patterns Free Patterns Images and Photos finder

Bolt Torque Patterns Free Patterns

Web Specify The Correct Tightening Torque:

Web Tests Have Shown That The Elastic Interaction Between Bolts In A Joint Can Have A Significant Effect On The Preload (A Reduction Of 35%).

Web The Graphic Below Shows The Three Common Bolt Patterns And Tightening Sequences, Appropriate For Most Automotive Applications.

This Torque Creates An Axial Force In The Bolt.

Related Post: