Tig Welding Weave Patterns

Tig Welding Weave Patterns - Web what's up guys and gals?! Web the weave pattern of walking the cup looks impressive, and the weld bead seems like you are putting on scales on a proper tig weld. The more movement you have in your weld pattern, the higher the degree of difficulty will be. Keep the tungsten electrode perpendicular to the workpiece. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. If you run into issues while tig welding, here are some common troubleshooting tips that can help: Keep the tig torch at a consistent angle and distance from the workpiece. Web to perform a weave bead in tig welding, the welder should: Plus, the increased energy transfer allows for a faster travel speed. Filler metal must be dry, free of oxides, grease, or other foreign matter. That happens because the fast. Weaves are much easier on vertical. Web tig welding troubleshooting tips. Web hello everyone.the wider the gap between the pipes, the wider the grooves that need to be filled.when the groove is wide, there are various methods of fillin. A new trending thing in the welding process is the “mig like tig” technique. There is a perception that tig welding to be a really precise but very slow welding process. Web the weave weld pattern is another advanced weld pattern that involves moving the welding gun from side to side along the joint. This creates an even and consistent heat distribution across the tight arc length of the weld area, which results in. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. A new trending thing in the welding process is the “mig like tig” technique. We’ll hit on the latter in a bit, but right now let’s focus on the former. Web there are basically two. A new trending thing in the welding process is the “mig like tig” technique. Web the most common sticking welding pattern is the weave. Keep the tungsten electrode perpendicular to the workpiece. Web the weave weld pattern is another advanced weld pattern that involves moving the welding gun from side to side along the joint. Web the six common mig. It’s by far the more popular method, and for good reason. There are several benefits of employing weaving patterns in. If your tungsten is melting into the weld puddle, use less current or a larger tungsten. Web a weave bead is a type of weld bead, typically used when time is limited and wider area needs to be welded. This. I searched but didn't come up with what i was looking for. A new trending thing in the welding process is the “mig like tig” technique. If filler metal becomes damp, heat for 2 hours at 250°f before using. Keep the tig torch at a consistent angle and distance from the workpiece. I've found that if i'm welding flat i. Web what's up guys and gals?! The more movement you have in your weld pattern, the higher the degree of difficulty will be. Now, you can get your mig weld bead to look like. This is a good technique to use when you are in the vertical welding position or the overhead welding position. Vary the size of the weaving. The weave weld pattern is more challenging to perform than the stringer or circle. Web although this can produce a sound weld, using a weave as a welding beads pattern can benefit wider joints and straight welds. Working uphill, the welder can use a variety of patterns to spread the filler metal into the joint. Web the weave pattern of. There are several benefits of employing weaving patterns in. That happens because the fast. This is a good technique to use when you are in the vertical welding position or the overhead welding position. If i'm welding horizontal a d pattern seems work work pretty good. In this video of a welder laying down a cap weave on a 6. There is a perception that tig welding to be a really precise but very slow welding process. Web tig weaves are some of my favorite welding exercises because they offer some gret challenges when it comes to torch positioning and puddle control. A circular motion can be a good technique for welding in the flat position. It’s by far the. The default waveform for the miller® diversion™ tig welding power source line is ‘soft squarewave’, which is a blend between a sine wave and square wave. In this video of a welder laying down a cap weave on a 6 pipe joint, you might notice that he is running pretty hot and pretty fast. The weave weld pattern is more challenging to perform than the stringer or circle. Now, you can get your mig weld bead to look like. Tungsten inert gas (tig) welding: Keep the tig torch at a consistent angle and distance from the workpiece. There is a perception that tig welding to be a really precise but very slow welding process. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. A circular motion can be a good technique for welding in the flat position. A new trending thing in the welding process is the “mig like tig” technique. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Web we'll talk about independent ac waveform control, gas selection, tig welding aluminum with dc tig, and techniques for welding anodized aluminum. Web there are basically two ways to weave a tig weld: Filler metal can be either wire or rod and should be compatible with the base alloy. Plus, the increased energy transfer allows for a faster travel speed. Web tig weaves are some of my favorite welding exercises because they offer some gret challenges when it comes to torch positioning and puddle control.

Tig weave

"The art of Welding" weavewednesday tig weldporn weldlicious

Pin by Jim Palmer on women welders Welding and fabrication, Welding

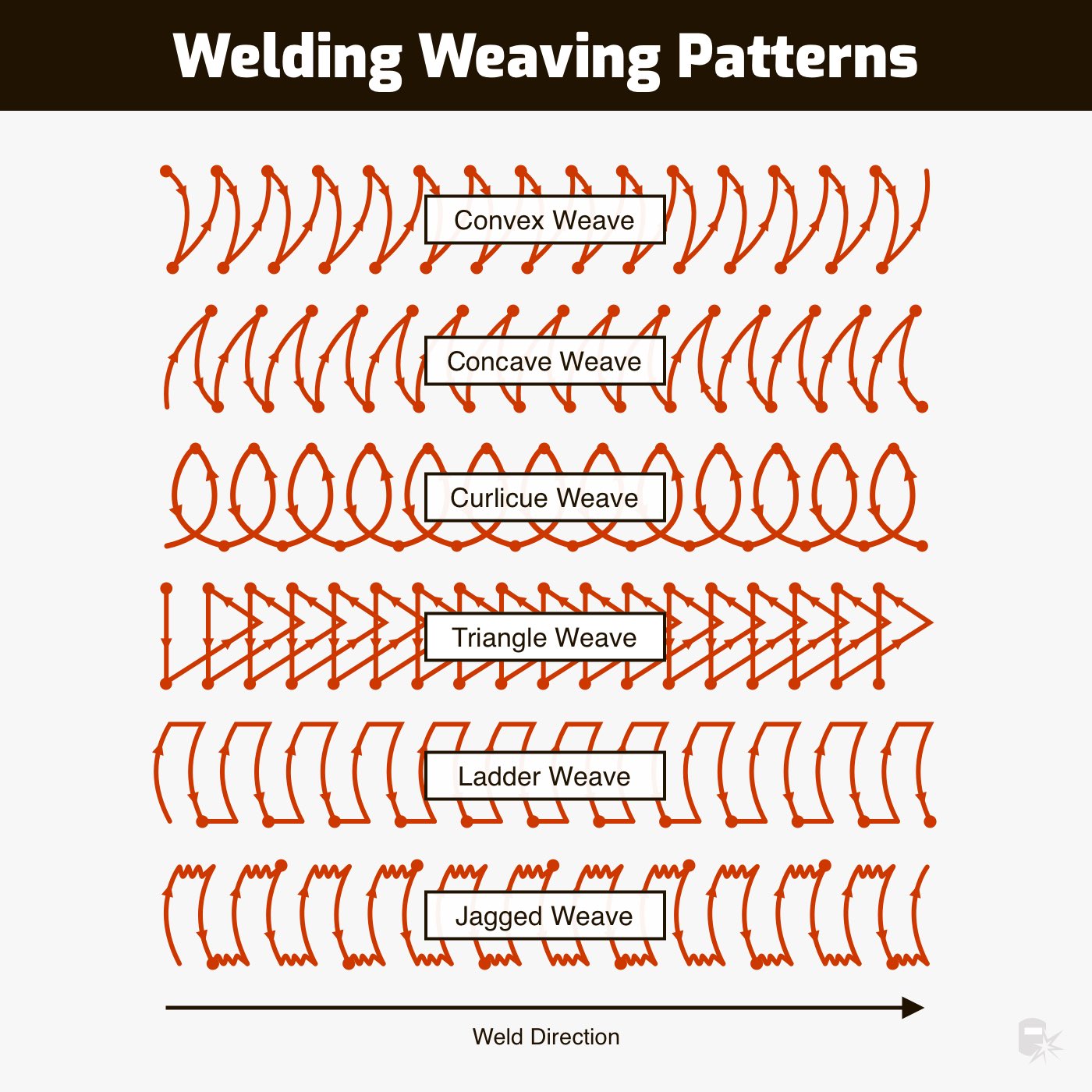

Weaving in welding A comprehensive guide to weave patterns

Welding Beads What Are They? & Different Types

HOW TO TIG WELD ALUMINUM HOW TO TIG A WEAVE WELD YouTube

TIG WELDING STAINLESS STEEL How to tig a WEAVE WELD! YouTube

How to TIG Weave with Weave Trainers YouTube

Tig weave Welding, Welding art, Tig welding

Tig weave Ремесло художественной сварки, Проекты по художественной

Stick Welding Beads The Filler Rods Used When Stick Welding Can Be Pretty Versatile And Produce Different Welding Bead Patterns Depending On The Technique Used.

Web A Weave Bead Is A Type Of Weld Bead, Typically Used When Time Is Limited And Wider Area Needs To Be Welded.

This Is A Good Technique To Use When You Are In The Vertical Welding Position Or The Overhead Welding Position.

All Patterns Have Pros And Cons, Difficulty Levels, And The Best Situations To Use Them.

Related Post: