Tig Welding Patterns

Tig Welding Patterns - Web another tig welding technique you might have heard of as a beginner is walking the cup. Web to begin stick welding, the stick welder must wear a welding helmet and safety gear and select a welding rod with the right electrode type. This document may be found here. The width of the flat tip should only be about 10% of the tungsten electrode width. Walking the cup and freehand. Web as an amazon associate i earn from qualifying purchases. The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld. To prevent contamination, it’s also important to avoid touching your tungsten. Get it as soon as thursday, may 16. Shop best sellersdeals of the dayfast shippingshop our huge selection Here are some of them: The four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave pattern. Plus, the increased energy transfer allows for a faster travel speed. It is the most complex of welding processes and takes considerable practice to master. Web the six. Web perhaps the most important skill needed for tig welding is moving the torch in a controlled manner, with steady forward movement, while keeping the gap between the tip of the electrode and the base metal consistently small — usually in the range of 1/8 inch to 3/16 inch. Web for information on welding machines and peripherals, you can get. The filler rods used when stick welding can be pretty versatile and produce different welding bead patterns depending on the technique used. The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld. Web tig welding troubleshooting tips. Web the six common mig welding patterns we’ll cover are the stringer, circle. The default waveform for the miller® diversion™ tig welding power source line is ‘soft squarewave’, which is a blend between a sine wave and square wave. Pws is able to assist customers in improving their production processes through equipment to enhance or improve welding quality. The more movement you have in your weld pattern, the higher the degree of difficulty. In this video we will be going over how to get started in tig welding from the most basic level. We’ll hit on the latter in a bit, but right now let’s focus on the former. If you run into issues while tig welding, here are some common troubleshooting tips that can help: The width of the flat tip should. Get it as soon as thursday, may 16. If you are going to weld either of these materials, you need a. Most people assume that all weaved tig welds are “walked.”. A) tungsten inert gas welding b) metal inert gas welding. This document may be found here. To prevent contamination, it’s also important to avoid touching your tungsten. Plus, the increased energy transfer allows for a faster travel speed. Web to maintain it’s growth pattern pws has developed a variety of products and many of the products we offer are of a “value added” nature. Most people assume that all weaved tig welds are “walked.”. We’ll hit. Web tig welding troubleshooting tips. Web another tig welding technique you might have heard of as a beginner is walking the cup. 30 day free trialtrusted by millionsmoney back guarantee5 star rated You need to set up your. Figure 4 provides an example of a weld done at 150 hz and 40 hz. Mig welding involves feeding a continuous wire electrode through a welding gun and creating an arc between the. Web this is our introduction to tig welding video. Web for information on welding machines and peripherals, you can get more accurate answers by contacting the manufacturer.↓↓↓↓↓↓↓korea@nswel.comhello everyone.th. Web vdom dhtml e>document moved. If your tungsten is melting into the weld puddle,. Shop best sellersdeals of the dayfast shippingshop our huge selection The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld. Web perhaps the most important skill needed for tig welding is moving the torch in a controlled manner, with steady forward movement, while keeping the gap between the tip of. Sold by yeswelder and ships from amazon fulfillment. You must always take the time to remove any dirt, dust, oil, grime, or other contaminants from the surface of the metal before starting. Tig welding works well in all positions on almost any metal. Just like any other welding process there is not a single pattern or way to make a good weld. If you run into issues while tig welding, here are some common troubleshooting tips that can help: The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld. If you are going to weld either of these materials, you need a. Web as an amazon associate i earn from qualifying purchases. Web setting the frequency from 120 to 200 hz provides an ideal frequency for most aluminum welding. Get it as soon as thursday, may 16. Gas tungsten arc welding (gtaw) is the process most often used to meet high aesthetic and quality standards. Here a weld pool will form, then a thin filler wire is fed by hand into the pool and melted, thus creating a joint. Web this will prevent tungsten erosion and tiny tungsten particles from contaminating the weld joint. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. A) tungsten inert gas welding b) metal inert gas welding. Tig welding isn’t forgiving of dirty material.

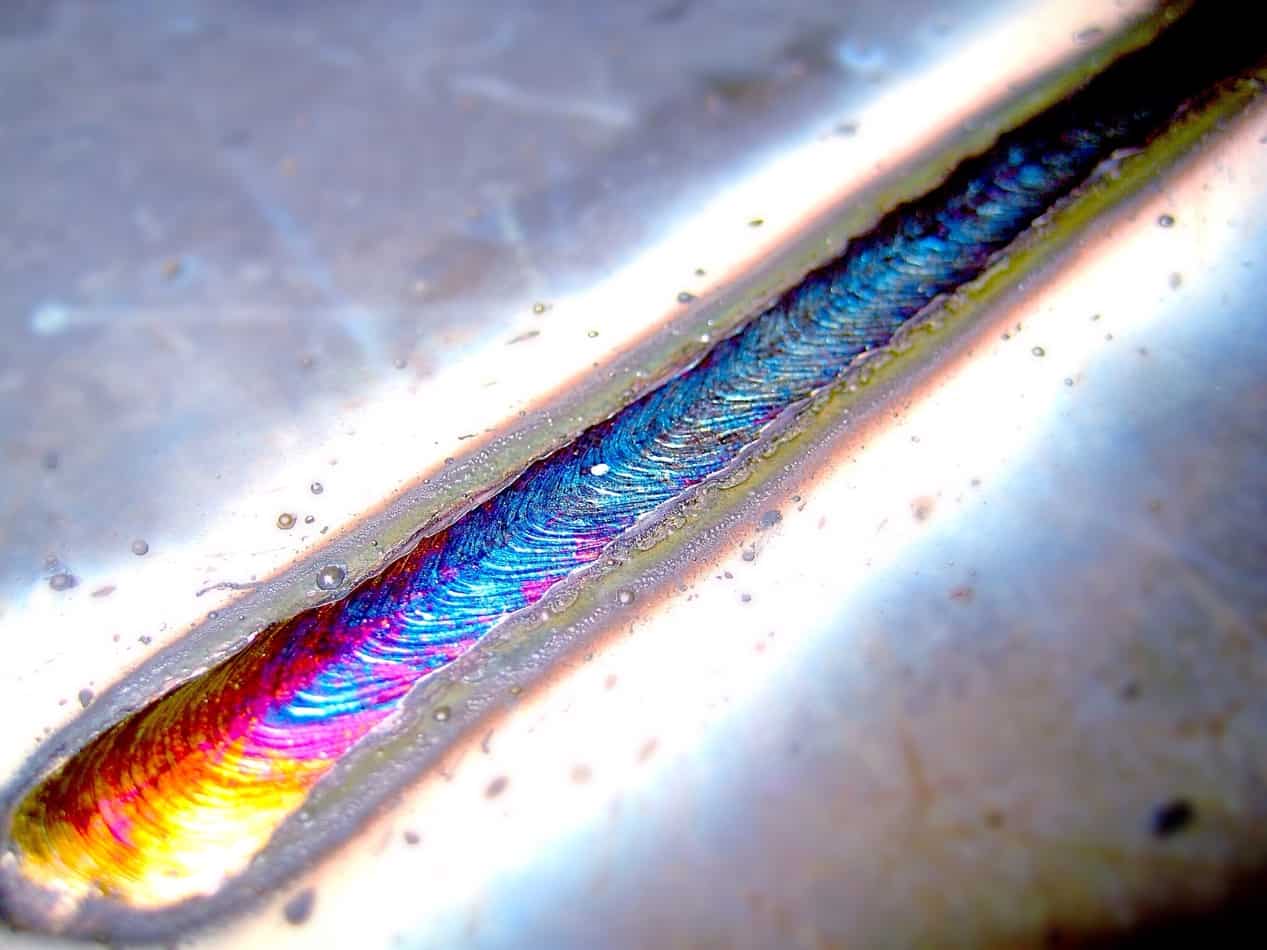

Tig weave Tig welding, Welding art, Welding and fabrication

HOW TO TIG WELD ALUMINUM HOW TO TIG A WEAVE WELD YouTube

Schematic Diagram of TIG welding process Download Scientific Diagram

21 Satisfyingly Beautiful Welds That Are Basically Works Of Art

ultimate tig weld Google Search Welding Cart, Welding Rigs, Mig

MIG vs TIG Welding Types, Materials, and Applications A Guide

best tig welding around the world YouTube

How To Make A Colorful TIG Weld The Complete Guide Welding Mastermind

21 Satisfyingly Beautiful Welds That Are Basically Works Of Art

Pin on tig welding

Web Mig Welding Can Be Improved And Refined By Applying Some Advanced Tips And Tricks That Can Enhance Your Skills And Results.

The Four Easiest Mig Welding Patterns For Beginners To Learn And Master Are The Steady Motion Pattern, The Whipping Pattern, The Circle Pattern, And The Weave Pattern.

The Default Waveform For The Miller® Diversion™ Tig Welding Power Source Line Is ‘Soft Squarewave’, Which Is A Blend Between A Sine Wave And Square Wave.

Web There Are Basically Two Ways To Weave A Tig Weld:

Related Post: