Table Saw Push Stick Pattern

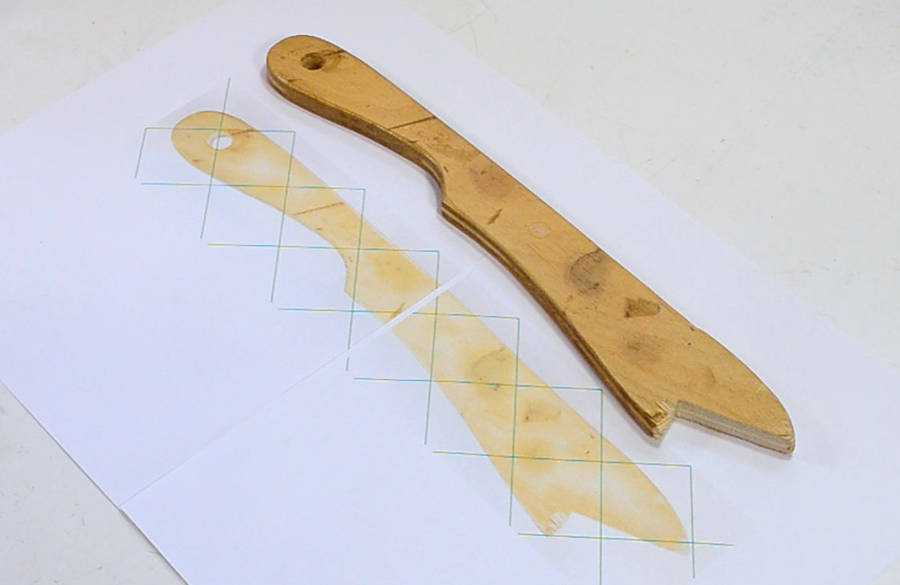

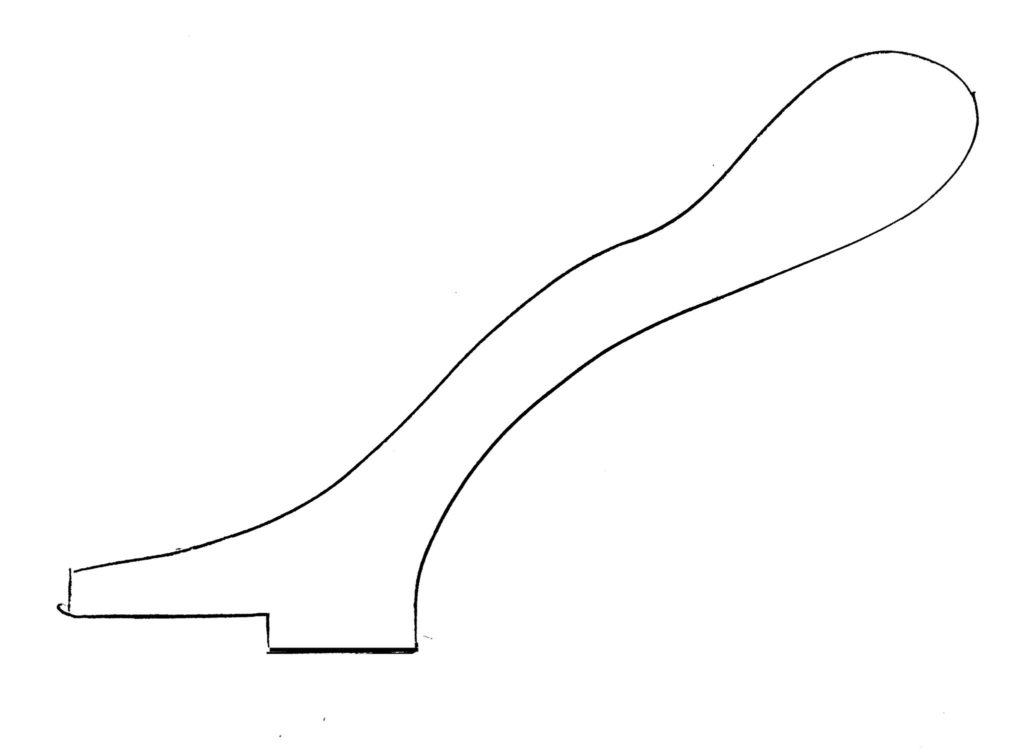

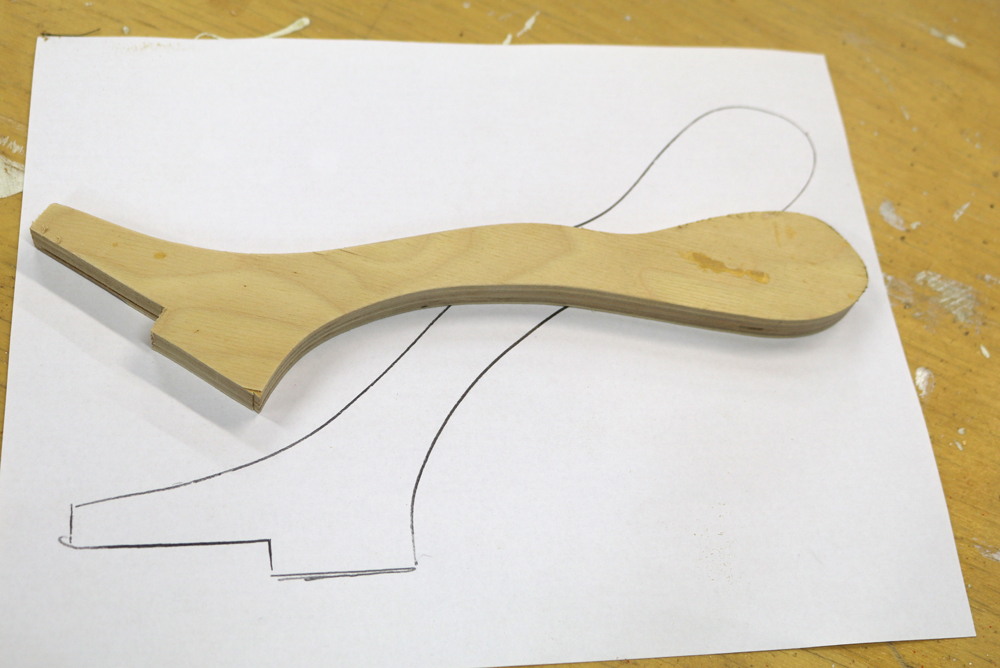

Table Saw Push Stick Pattern - Drill, set threaded insert, and finish. The hole for the threaded insert should be centered on the back, at least 1″ up from the bottom (higher is better). Checking the printout against the original. It is typically attached to one or both of the guide rails. Web push stick is a safety device that helps you to control movement of working piece when operate on some of the machines, especially when working on table saw, jointer, router table or a band saw. Web the push stick is 32 cm long, so i select points at either end and enter 32 cm to scale it to that. Web push stick comparison table saw push stick vs table saw fence. I have lots of it in my shop to make extra blades with when it's time, and it's plenty sturdy to hold up to frequent use. We were all beginners once! Therefore, avoid using them when a high downward pressure. Woodwork junkie push stick marking diagram. Table saw push sticks are vital for safety and make a great first woodworking project. 1) push block w/2 alt handles + push sticks. Web 3) table saw push stick. The rim speed of the blade hurls the stock at you. Web when i point my index finger on top and wrap the rest of my hand under the handle, the push stick becomes an extension of my hand and i can better control how and where i direct the pressure. Notched push sticks allow the woodworker to apply forward pressure, but their major disadvantage is a slight downward pressure. This. It is typically attached to one or both of the guide rails. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. It does this by applying downward pressure on the stock. Use adhesive spray to attach the pattern to the wood and cut. The rim speed of the. This will be the cutting line. I can usually get two push sticks out of one piece of scrap baltic birch. Size on your printer settings until squares measure 1 inch. Try it for yourself with either a free downloadable template or purchase one made here for you in t. Web this push stick helps prevent kickback. Size on your printer settings until squares measure 1 inch. Web is this the new best push stick design for the table saw? Using the marked lines as a guide, free hand draw a curved edge for a more comfortable look and feel. Checking the printout against the original. Use sandpaper to smooth out the handle and round edges. Web 3) table saw push stick. In the worst of cases, your hand is dragged into the blade. Round the edges to give it ergonomic shape with a rasp. Web the push stick is 32 cm long, so i select points at either end and enter 32 cm to scale it to that. It is typically attached to one or. Check out the video on how to make it and here are some images and the stencil that you can print out, trace and replicate. This is a very simple template for push sticks. The next step here is to go online and to find a push stick template, more or less just a shape that you can print out. You can easily make one too just download the pattern below #pushstic. I traced one of my push sticks and made a pattern for you,. Push stick keeps your hands away from machine cutting zone, it also helps to produce a smoother cuts. The hole for the threaded insert should be centered on the back, at least 1″ up from. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. We were all beginners once! It is typically attached to one or both of the guide rails. I'm using 6mm plywood for my push stick. I make sure i cut the long hooks for the two push sticks first. Using a marking tool that produces a more prominent line or a different color can make differentiating between the lines easier. Use sandpaper to smooth out the handle and round edges. Web this push stick helps prevent kickback. I can usually get two push sticks out of one piece of scrap baltic birch. When installing a new fence, it should. Push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. The next step here is to go online and to find a push stick template, more or less just a shape that you can print out on paper. It does this by applying downward pressure on the stock. 1) push block w/2 alt handles + push sticks. Web pictures from these plans. Use adhesive spray to attach the pattern to the wood and cut. Table saw push sticks are vital for safety and make a great first woodworking project. Web this push stick helps prevent kickback. You can easily make push sticks out of scrap plywood that you have laying around the shop. Try it for yourself with either a free downloadable template or purchase one made here for you in t. Use good quality straight scrap wood. In the worst of cases, your hand is dragged into the blade. Web the push stick is 32 cm long, so i select points at either end and enter 32 cm to scale it to that. Now that you’ve finished cleaning up the table saw push stick, it’s time to drill the hole for threaded insert. When installing a new fence, it should always be checked for squareness and alignment with. And why these are the best push sticks and sanding blocks.

Woodworking Template Table Saw Push Sticks Kurt's Blog

50 Extreme Table Saw Push Stick Safest Design FREE PLANS YouTube

Table saw push stick DIY » Famous Artisan

Adjustable Table Saw Push Stick Plans The Every Maker

Push Stick / The Wood Whisperer Store Easy woodworking ideas, Plywood

Making table saw push sticks

Pattern Table Saw Push Stick Printable Template Printable Templates

PushStick for Table Saw Free Design Plans Longview Woodworking

Build the Best Tablesaw Push Stick Ever! Evening Woodworker YouTube

PushStick for Table Saw Free Design Plans Jon Peters

Once You Have Printed Out The Specific Push Stick Design That You Want, Cut It Out As Accurately As You Can.

I'm Using 6Mm Plywood For My Push Stick.

Using A Marking Tool That Produces A More Prominent Line Or A Different Color Can Make Differentiating Between The Lines Easier.

If Using A Table Saw Is A Little Intimidating To You, You’re Not Alone!

Related Post: