Stick Welding Patterns

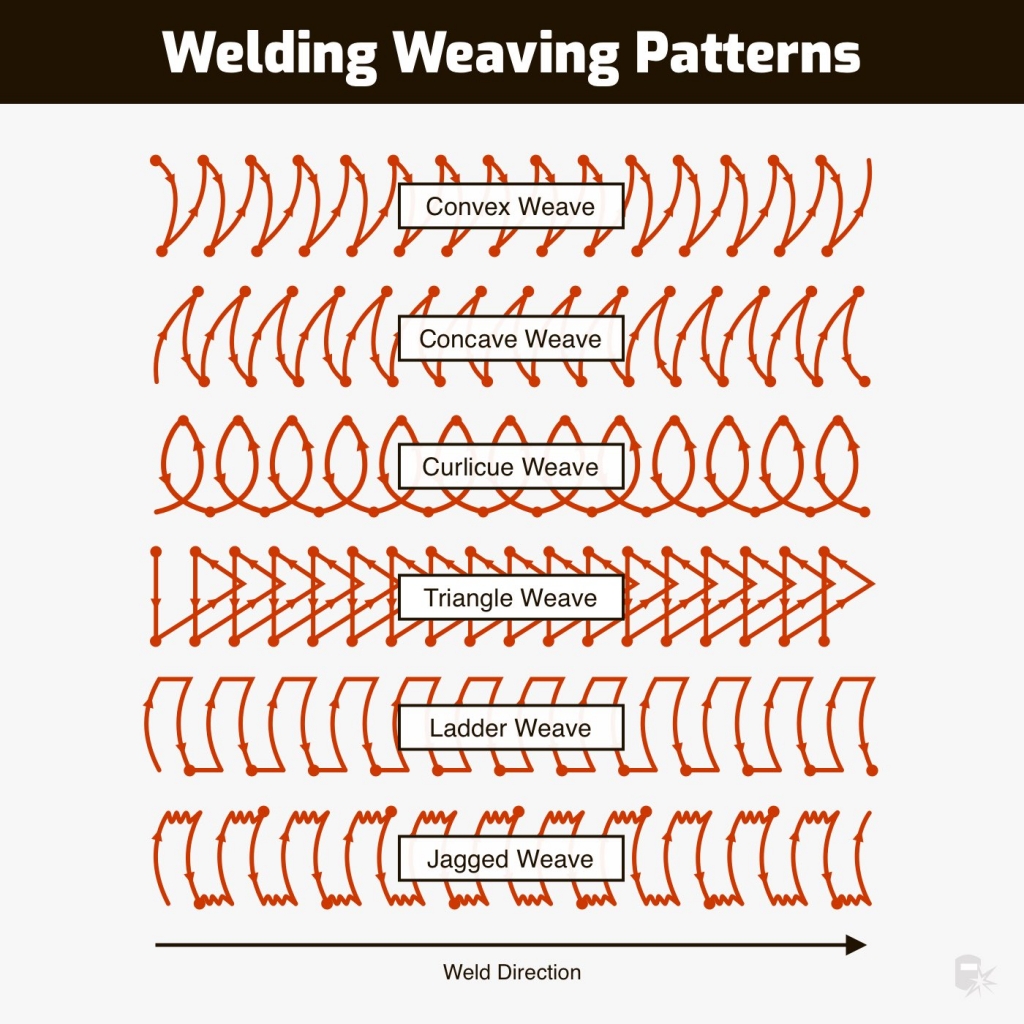

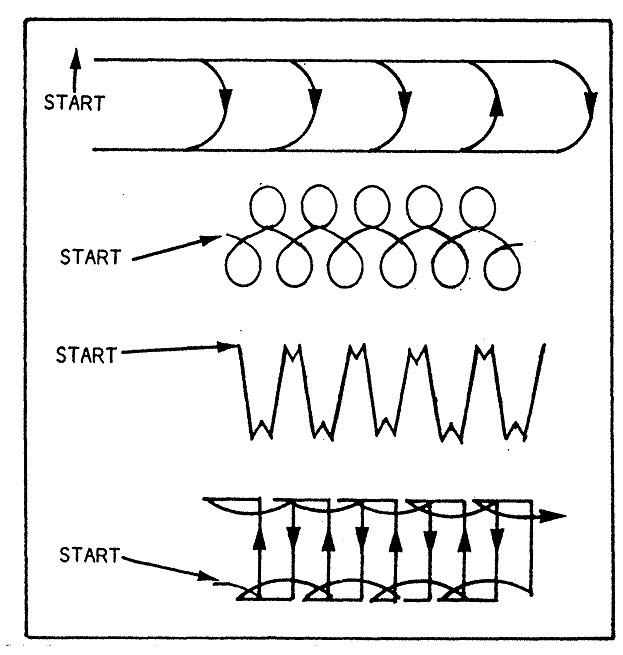

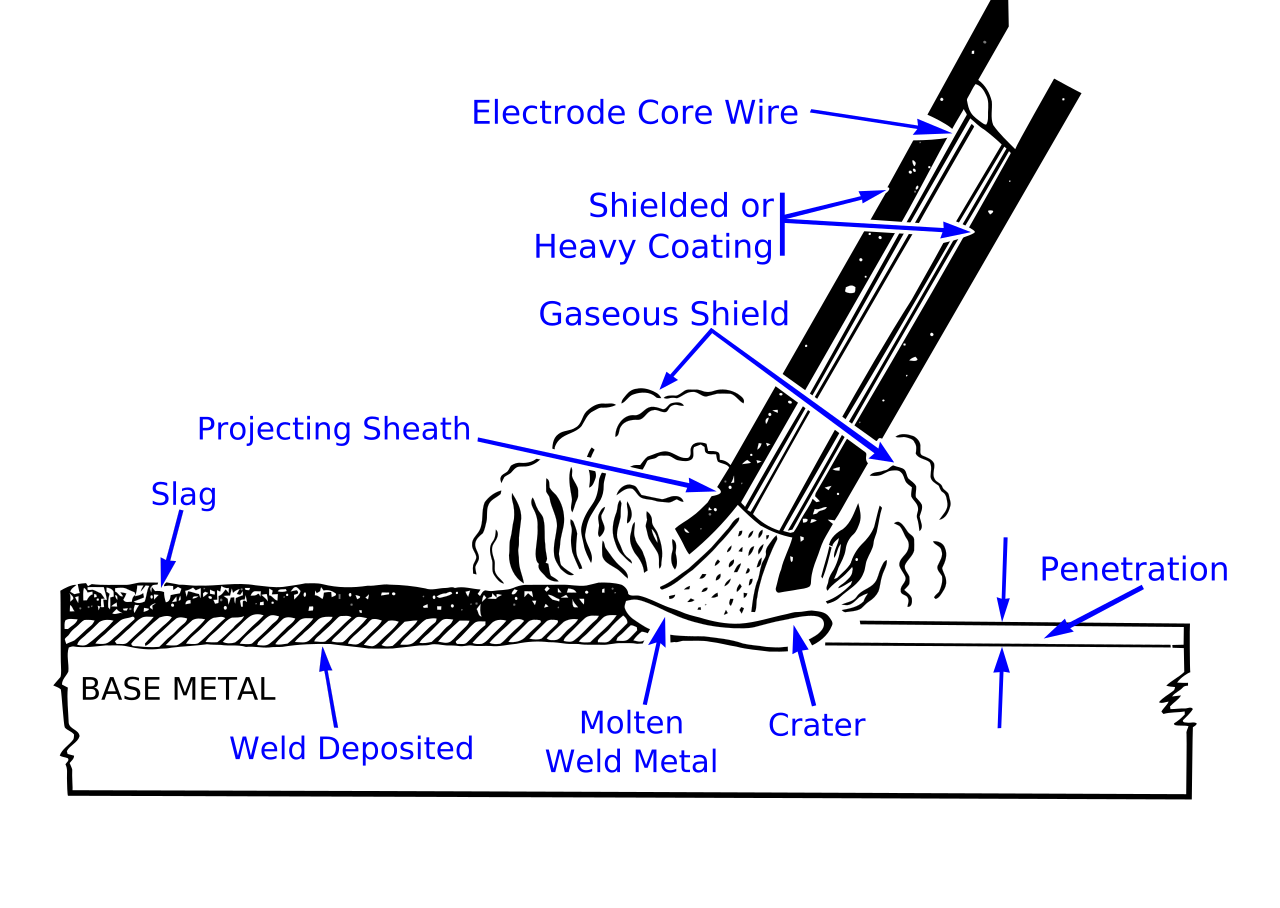

Stick Welding Patterns - The reason why many people refer to it like this is that the electrode used to weld the metal is in the form of a stick. This pattern allows the heat to be concentrated on the thicker plate. When welding metal horizontally on a flat surface, it’s easy to drag the separate filler rod to lay a stringer bead. Web stick welding setup. Web stick welding, also known as shielded metal arc welding (smaw), uses an electric current to create a short circuit between the electrode and the base material. The melted metal pools combine and cool together as they solidify, forming a strong. Don’t increase your current too much due to the potential for undercut. Move the rod to the other toe in a straight line and pause for one second. The perfect welding technique is many hours of practice! Web while stick welding may be the most forgiving process on dirty or rusty metal, don't use that as an excuse for not properly cleaning the material. Web stick welding, also known as shielded metal arc welding (smaw), uses an electric current to create a short circuit between the electrode and the base material. Web the operator performing stick welding. Stick welding uses a metal filler rod, or stick, coated with flux. There are two ways to start the arc. We prefer close to 90 to get. We prefer close to 90 to get a flatter bead. An electric current flow through the electrode and melts it in the workpiece, creating a weld pool. Web stick welding setup. Learn how to stick weld or improve your skills with miller stick welding resources. The steel of grade 1015 and 1025 work fine for stick welding because of lower. The steel of grade 1015 and 1025 work fine for stick welding because of lower than 0.035% sulfur, 0.1% silicon. You create the puddle over the edge (toe) of the previous bead. We prefer close to 90 to get a flatter bead. Web first stick welding lesson is how to run straight consistent beads. Follow the manufacturer’s procedure recommendations. Stick welding with multimatic 255. An electric current flow through the electrode and melts it in the workpiece, creating a weld pool. This pattern allows the heat to be concentrated on the thicker plate. Stick welding is a fairly straightforward set up that will look something like the image below. Web stick welding tips, training materials, weld calculator and more. The electrode is covered with a layer of flux that softens the weld pool and protects it from contamination by the atmosphere (in the same way a shielding. Web stick welding is a slang term that the industry has adopted for the process technically called shielded metal arc welding. Aside from being the electrode, the wire also serves as the. Move the rod to the other toe in a straight line and pause for one second. If you touch it (or any of the other metal components in the stick welder), you will be subject to a shock between 115 to 600 volts. As the stick material melts in the heat, the flux coating also melts, creating both a gas. When welding metal horizontally on a flat surface, it’s easy to drag the separate filler rod to lay a stringer bead. Stick welding is a fairly straightforward set up that will look something like the image below. Web advanced techniques in stick welding. The reason why many people refer to it like this is that the electrode used to weld. Grind the metal surface so that the metal underneath is shiny. Web mig (metal inert gas) or gmaw (gas metal arc welding) is a method that uses a roll of solid wire electrodes, instead of a stick welding electrode. Move the rod to the other toe in a straight line and pause for one second. Web advanced techniques in stick. If you touch it (or any of the other metal components in the stick welder), you will be subject to a shock between 115 to 600 volts. Web grind the mill scale off the surface, remove rust, and clean any dirt and grime before doing any stick welding. You can do this with a grinder. The electrode is covered with. An electric current flow through the electrode and melts it in the workpiece, creating a weld pool. Involves alternating between high and low currents to improve control. Advanced stick welding techniques can enhance weld quality and efficiency: Web while stick welding may be the most forgiving process on dirty or rusty metal, don't use that as an excuse for not. Web advanced techniques in stick welding. Web the current you need depends on the size of rod you are using. Stick welding with multimatic 255. Web the filler rods used when stick welding can be pretty versatile and produce different welding bead patterns depending on the technique used. Undercut in stick welding is mainly caused by too high current or fast travel speed. Then move the rod to the starting side in a diagonal line with a tight angle and pause again. When welding metal horizontally on a flat surface, it’s easy to drag the separate filler rod to lay a stringer bead. To get started try some 6013 electrodes on dcen on some 3/16 inch steel plate. Web first stick welding lesson is how to run straight consistent beads. Overtime your hands, eyes and body positioning automatically adjust to the weld needed and your patterns change as. As the stick material melts in the heat, the flux coating also melts, creating both a gas and a liquid slag, which act to shield the weld from oxidation. This is the primary electric shock. Web stick welding tips, training materials, weld calculator and more. Web as soon as the stick welder is plugged in, the electrode will become what is known as electrically hot. The reason why many people refer to it like this is that the electrode used to weld the metal is in the form of a stick. Web the stick welding tips and tricks:

Welding Beads What Are They? & Different Types

Welding Techniques

STICK WELDING 101 Getting Started With SMAW YouTube

Beginner practicing vertical up with stick. Any tips? Welding gear

How To Stick Weld StepbyStep Guide and Safety Tips

The Beginner’s Guide to Sticking Welding Patterns MIG, TIG & Stick Weld

The Beginner’s Guide to Sticking Welding Patterns MIG, TIG & Stick Weld

Simple stick welding project for beginners YouTube

Finally decided to learn how to stick. r/Welding

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding

Learns About The Basics Of Stick Welding Terms, Common Questions, Basic Equipment, How Stick Welding Works, Welder Safety, Joint Preparation.

Stick Welding In The Flat, Horizontal And Overhead Positions Uses A Drag Or Backhand Welding Technique.

Web Stick Welding Is Performed By Starting An Arc Between A Metal Electrode And The Workpiece.

Web Angle Of Travel:

Related Post: