Stick Welding Pattern

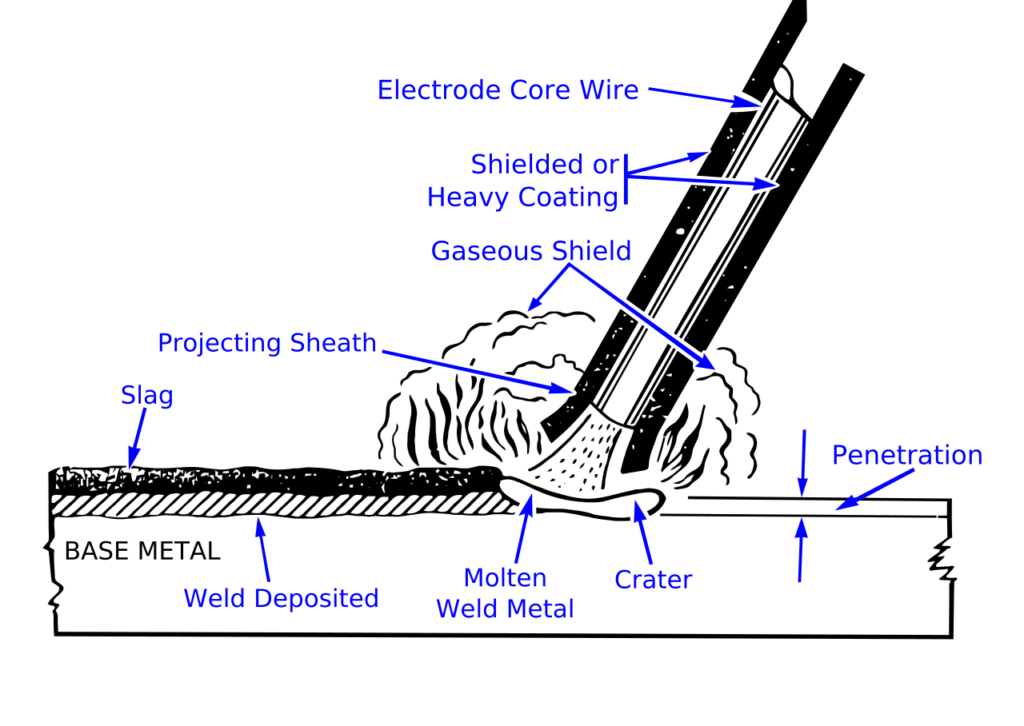

Stick Welding Pattern - Then move the rod to the starting side in a diagonal line with a tight angle and pause again. Web angle of travel: The melted metal pools combine and cool together as they solidify, forming a strong. This is the primary electric shock. Web a rule of thumb for stick welding electrode size is to select an electrode with a diameter smaller than the base metal thickness. Manipulating the electrode in a consistent pattern, such as a weave or whip motion, can help control the weld pool and produce a uniform weld bead. Web stick welding is a slang term that the industry has adopted for the process technically called shielded metal arc welding. Web if you're new to stick welding, here are a few different ways you can avoid sticking your electrodedownload the weld™ app, join the welding community, find w. The steel of grade 1015 and 1025 work fine for stick welding because of lower than 0.035% sulfur, 0.1% silicon. Web stick welding tips, training materials, weld calculator and more. There are two ways to start the arc. Web stick welding in the flat, horizontal and overhead positions uses a drag or backhand welding technique. Then move the rod to the starting side in a diagonal line with a tight angle and pause again. Advanced stick welding techniques can enhance weld quality and efficiency: Stick welding in the flat, horizontal. Stick welding with multimatic 255. Web stick welding setup. Web while stick welding may be the most forgiving process on dirty or rusty metal, don't use that as an excuse for not properly cleaning the material. This technique results in a flat bead that is relatively straight and narrow. Hold the rod perpendicular to the joint and tilt the top. Web about press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features nfl sunday ticket press copyright. Move the rod to the other toe in a straight line and pause for one second. Manipulating the electrode in a consistent pattern, such as a weave or whip motion, can help control the weld. Web focus on the most important things first, the rest will come.learn to weld in my $39 online courses: Web let's go over everything that you need to know when starting out with shielded metal arc welding (smaw), also known as stick welding. Involves alternating between high and low currents to improve control. You create the puddle over the edge. Web stick welding in the flat, horizontal and overhead positions uses a drag or backhand welding technique. Web let's go over everything that you need to know when starting out with shielded metal arc welding (smaw), also known as stick welding. To cover a wider area, make multiple passes or use stringer beads. Web stick welding is a slang term. You create the puddle over the edge (toe) of the previous bead. Web stick welding in the flat, horizontal and overhead positions uses a drag or backhand welding technique. For example, if you’re welding ¼” thick metal, your electrode diameter should be less than ¼”. Hold the electrode perpendicular to the joint, and then tilt the top in the direction. Web stick welding techniques. Web stick welding is a slang term that the industry has adopted for the process technically called shielded metal arc welding. Web stick welding setup. As the current passes through the gap, it causes an arc that creates heat and melts both materials. Web angle of travel: Repeat steps 2 and 3 until you finish. You create the puddle over the edge (toe) of the previous bead. Involves alternating between high and low currents to improve control. Web “j” patterns work well on flat (1f) lap joints, all vertical (3g) joints, and horizontal (2g) butt and lap (2f) welds. Heavy and rigid plates with high sulfur and. Web stick welding tips, training materials, weld calculator and more. Web a rule of thumb for stick welding electrode size is to select an electrode with a diameter smaller than the base metal thickness. Move the rod to the other toe in a straight line and pause for one second. Web stick welding, also known as shielded metal arc welding. Stick welding is a fairly straightforward set up that will look something like the image below. Web stick welding is a slang term that the industry has adopted for the process technically called shielded metal arc welding. Hold the electrode perpendicular to the joint, and then tilt the top in the direction of travel approximately 5 to 15 degrees. To. Then move the rod to the starting side in a diagonal line with a tight angle and pause again. Learns about the basics of stick welding terms, common questions, basic equipment, how stick welding works, welder safety, joint preparation. The reason why many people refer to it like this is that the electrode used to weld the metal is in the form of a stick. Manipulating the electrode in a consistent pattern, such as a weave or whip motion, can help control the weld pool and produce a uniform weld bead. Involves alternating between high and low currents to improve control. Heavy and rigid plates with high sulfur and silicon content will crack on. The arc will start easier and be more stable, the weld will penetrate better, and fewer weld defects will occur. Web angle of travel: Web as soon as the stick welder is plugged in, the electrode will become what is known as electrically hot. Web in this article, we will explore the ins and outs of stick welding, including its applications, key considerations for welding different materials, essential equipment, and safety gear,. The perfect welding technique is many hours of practice! For example, if you’re welding ¼” thick metal, your electrode diameter should be less than ¼”. Web stick welding setup. To get started try some 6013 electrodes on dcen on some 3/16 inch steel plate. If you touch it (or any of the other metal components in the stick welder), you will be subject to a shock between 115 to 600 volts. The melted metal pools combine and cool together as they solidify, forming a strong.

Stick Welding Tips 3 welders YouTube

How To Stick Weld A Comprehensive Guide For Beginners IHSANPEDIA

Welding Equipment Techniques, Technologies and Industrial Applications

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding

Here's What You Need to Know About Stick Welding Pros, Cons, Cost and

How To Stick Weld StepbyStep Guide and Safety Tips

Stick Welding 5 Elements of Technique Diagram Quizlet

How To Stick Weld For Beginners UNUGTP News

The Beginner’s Guide to Sticking Welding Patterns MIG, TIG & Stick Weld

STICK WELDING 101 Getting Started With SMAW YouTube

There Are Two Ways To Start The Arc.

Web While Stick Welding May Be The Most Forgiving Process On Dirty Or Rusty Metal, Don't Use That As An Excuse For Not Properly Cleaning The Material.

Web Focus On The Most Important Things First, The Rest Will Come.learn To Weld In My $39 Online Courses:

Web Stick Welding Tips, Training Materials, Weld Calculator And More.

Related Post: