Slipjoint Knife Patterns

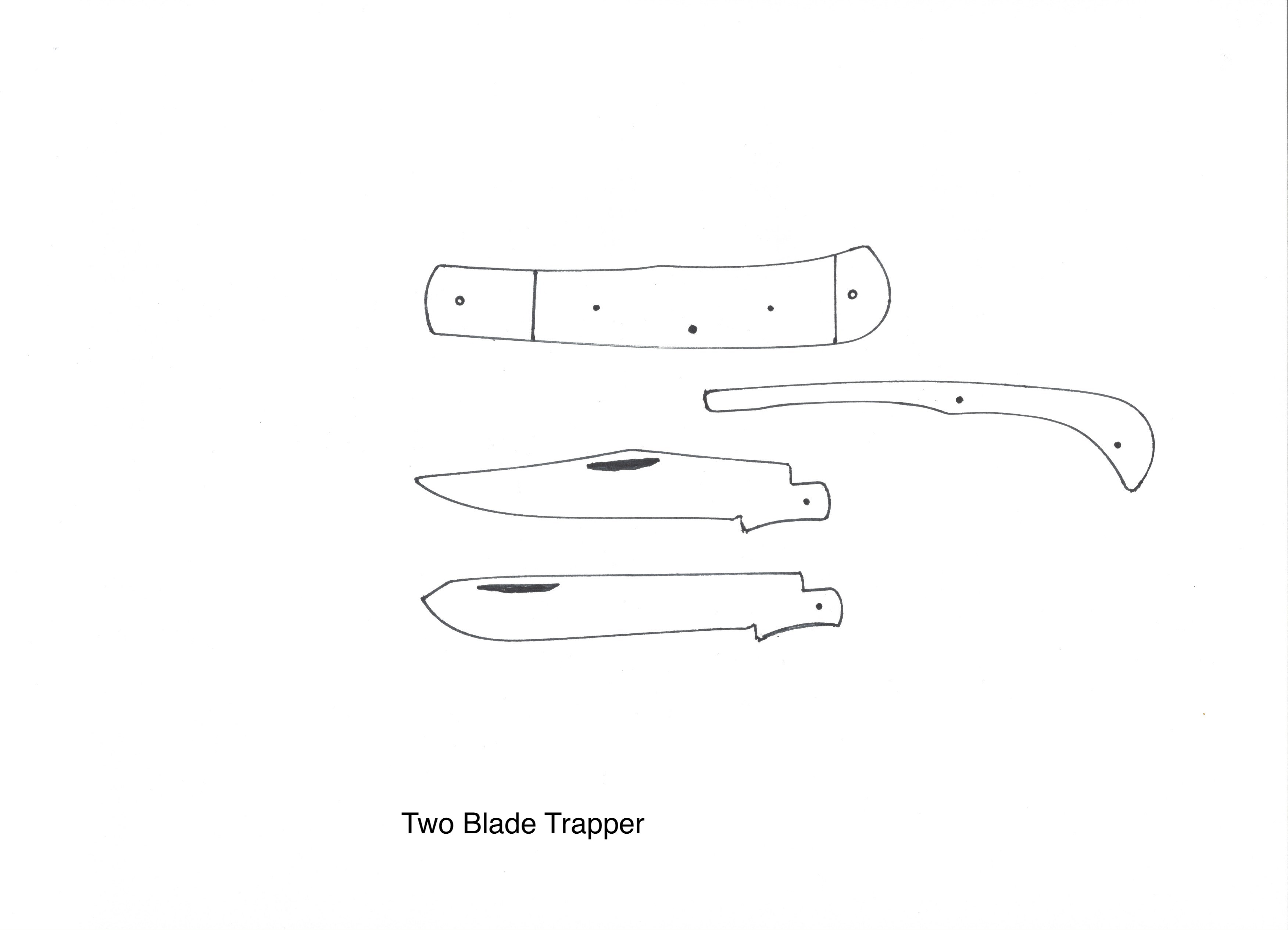

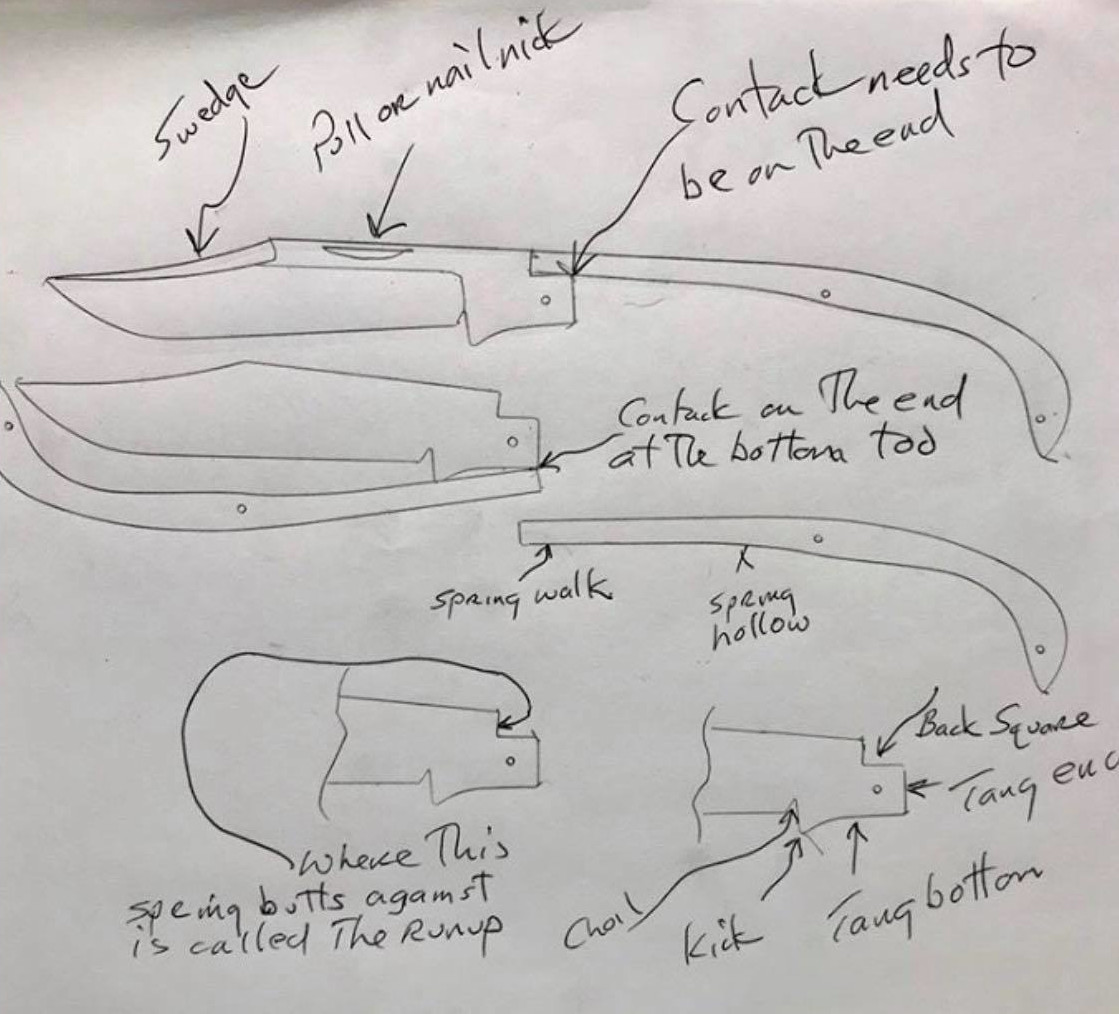

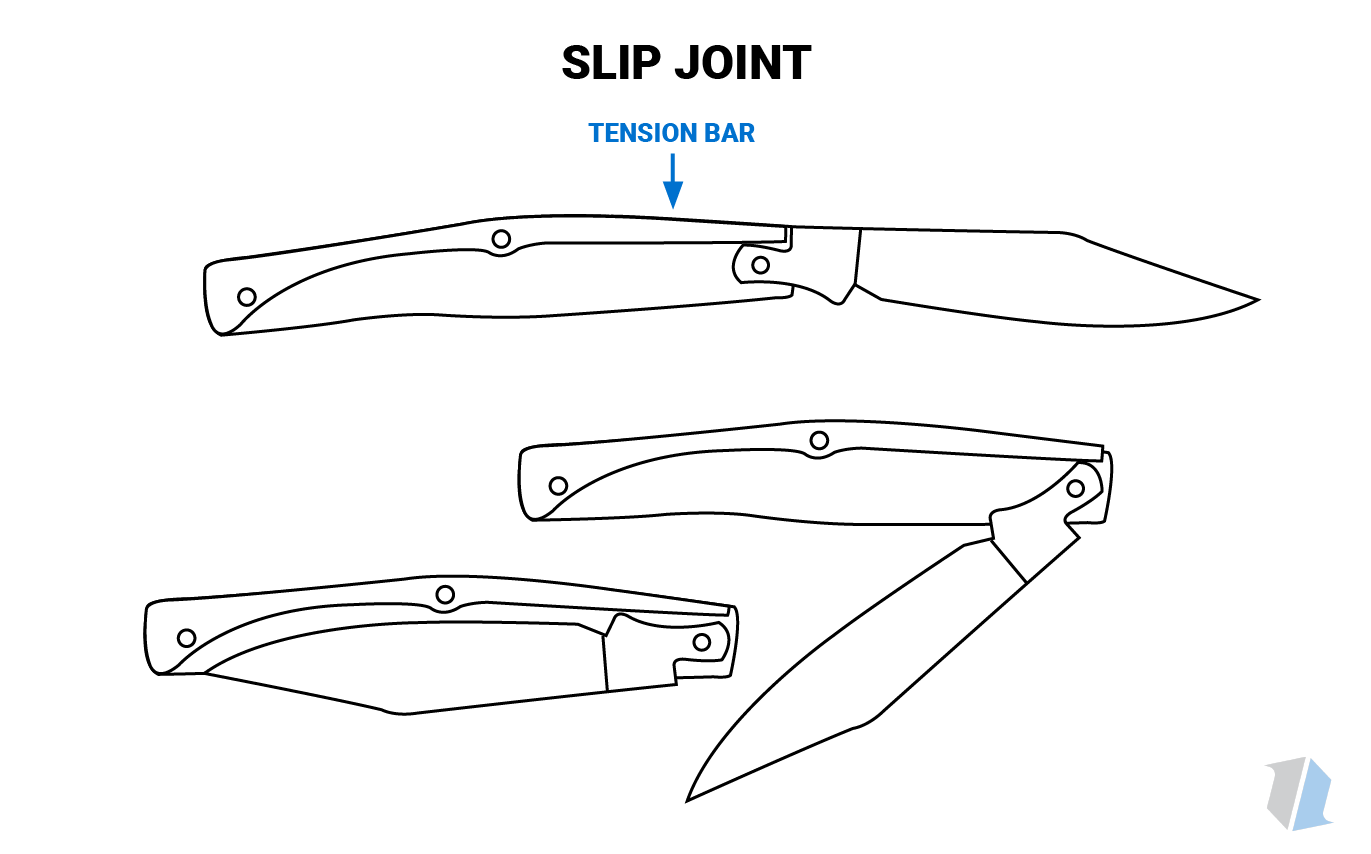

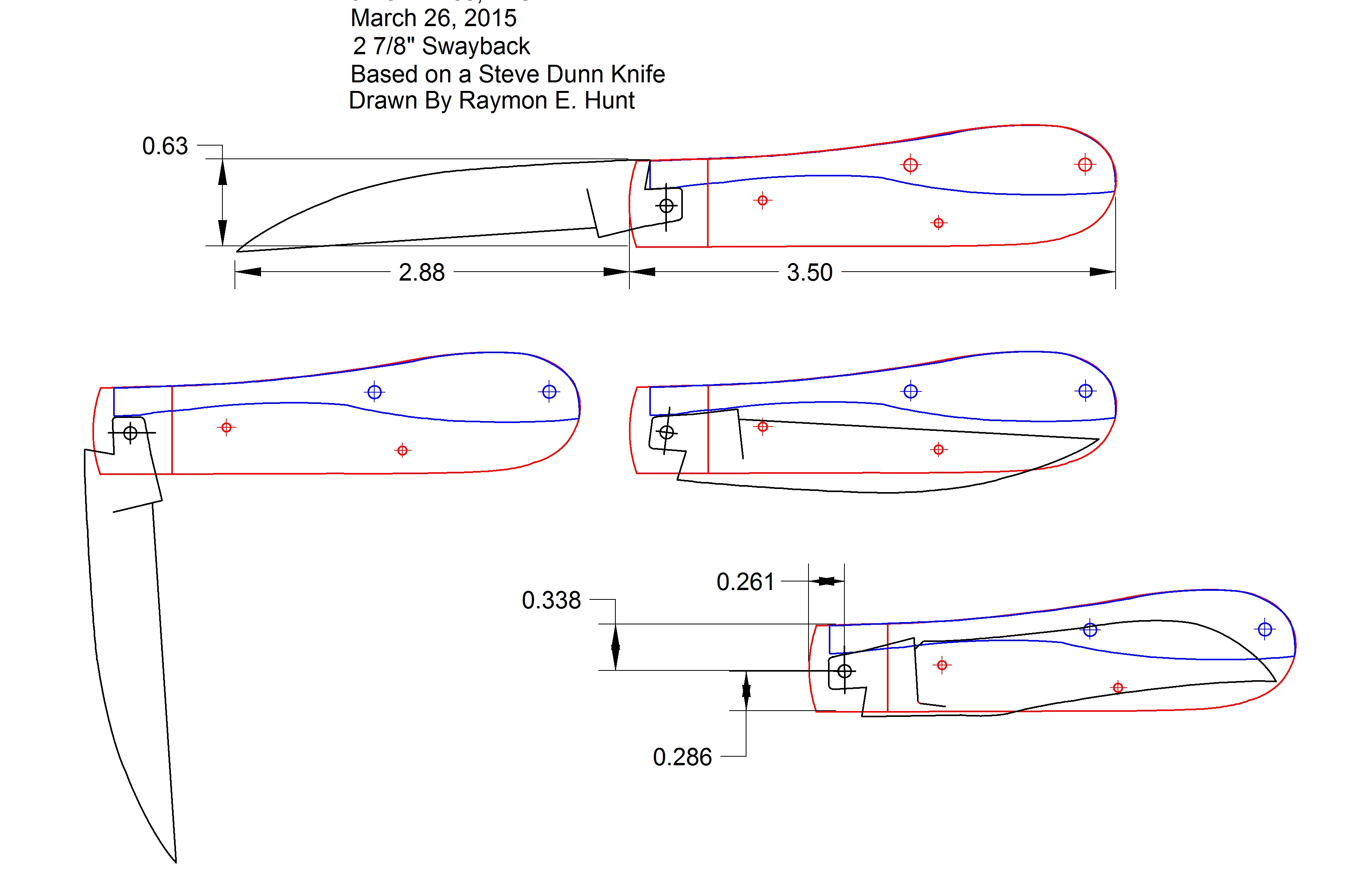

Slipjoint Knife Patterns - Throughout the process of making the knife, the knife pieces will need to be flat sanded to keep them smooth. First decide how long the bolsters should be and draw them off on the liner. Opening and closing the knife requires the user to overcome the tension of a spring in the back of the knife. Here we look at some of the best modern takes on the classic style of knife. Your holes need to be bang on and this is the best way (short of a milling machine) to accomplish this that i am aware of. For reasons i'll never understand the stockman and the camp. This method of designing a folding knife joint, is based on the size relationship between the height of the blade at the ricasso, the height of the blade tang and the height of the portion of the spring that functions against the. Now that we have the mechanical workings of the knife finished, it’s time to turn our attention to making the sides. There's nothing handier in the pocket besides a pocket knife. We always come back to. Web custom patterns are also accepted, as long as they're your own design. Web take a black magic marker and color in enough of the 01 to allow the outline of the blade and spring to be scribed onto the steel. The history of the stockman is nearly impossible to track, but gary zinn of chuckhawks.com speculates it was made. Outside of the sak i would guess trapper, stockman, jack, barlow, sodbuster and pen to be the top slipjoint patterns for the last 50 years. If i can do it, anyone can. A handle that curves slightly towards the end and has two blades characterizes the copperhead. The history of the stockman is nearly impossible to track, but gary zinn. My way” by don robinson, who is also a contributor here. This design is shown with a 1/8 pivot. If i can do it, anyone can. Web for the knife i will be designing in this tutorial i was inspired by a reese bose shadow pattern construction folder. For email, please send your pattern to knives@chriscrawford.com. Knife have always been my favorites. Now that we have the mechanical workings of the knife finished, it’s time to turn our attention to making the sides. Paper patterns can be directly mailed to: Take a folded piece of tape and stick it to one side of the blade. Use a metal cutting band saw to roughly cut the blade. We use the file guide to take a little at a time off the run up, keeping the correct angle, until the blade is flowing out of the knife handle the way you want it. Cut the bolsters out with a band. Use a metal cutting band saw to roughly cut the blade and spring out of the 01. This. There's nothing handier in the pocket besides a pocket knife. The buck 110 and similar style lock blade hunters are not slipjoints but are certainly very popular, however i believe that opinel locking ring knives far exceed their popularity over the. Most people are familiar with the slipjoint mechanism thanks to the venerable swiss army knife. The case trapper knives. Web pin the spring pattern to the handle pattern and pin the new blade in the pivot hole. Cut the bolsters out with a band. Web the trapper is a long popular slip joint knife pattern that usually pairs a clip main blade with a long spey blade. It could be anything from a sak. The history of the stockman. Web for the knife i will be designing in this tutorial i was inspired by a reese bose shadow pattern construction folder. Your holes need to be bang on and this is the best way (short of a milling machine) to accomplish this that i am aware of. If you'd like to submit a pattern, you can do so through. We always come back to. Web along with the trapper pocket knife pattern, the stockman is one of the best and most iconic american slipjoint patterns ever created. The case trapper knives (in various sizes) are classic trapper knives. Throughout the process of making the knife, the knife pieces will need to be flat sanded to keep them smooth. Web. My way” by don robinson, who is also a contributor here. Knife have always been my favorites. Place a piece of sandpaper on a very flat surface, and rub the blade back and forth by holding on to the tab of tape. Using the old blade and spring as a pattern, scribe around each. Your holes need to be bang. Web traditional slip joint knives are both classic and classy. There's nothing handier in the pocket besides a pocket knife. Paper patterns can be directly mailed to: This knife is based directly on his template from the book. Web take a black magic marker and color in enough of the 01 to allow the outline of the blade and spring to be scribed onto the steel. Web for the knife i will be designing in this tutorial i was inspired by a reese bose shadow pattern construction folder. Web optical center punch. It could be anything from a sak. Now that we have the mechanical workings of the knife finished, it’s time to turn our attention to making the sides. Outside of the sak i would guess trapper, stockman, jack, barlow, sodbuster and pen to be the top slipjoint patterns for the last 50 years. Web most people are familiar with the slipjoint mechanism thanks to the venerable swiss army knife. Some of the younger generations call these knives slippies, but. This is a nice design to cut out of plastic or timber to get an idea of how the mechanism operates. Throughout the process of making the knife, the knife pieces will need to be flat sanded to keep them smooth. The tip of the blade should be pointing a little down toward the closed position. My way” by don robinson, who is also a contributor here.

Patterns

Printable Folding Knife Templates

Patterns

Top 5 Slip Joints (Traditional Pattern) Pocket Knives YouTube

H.K. Parker Custom Knife Damascus Slip Joint Knife Purveyor

Slip Joint Printable Folding Knife Templates

Knife Lock Types Guide Knife Life

Patterns

Pin on Knife Lore

Bill Ruple Custom Knife Carbon Fiber Shadow Pattern Slip Joint Knife

Use A Metal Cutting Band Saw To Roughly Cut The Blade And Spring Out Of The 01.

Knife Have Always Been My Favorites.

Cut The Bolsters Out With A Band.

Web Pin The Spring Pattern To The Handle Pattern And Pin The New Blade In The Pivot Hole.

Related Post: