Shear Wall Nailing Pattern

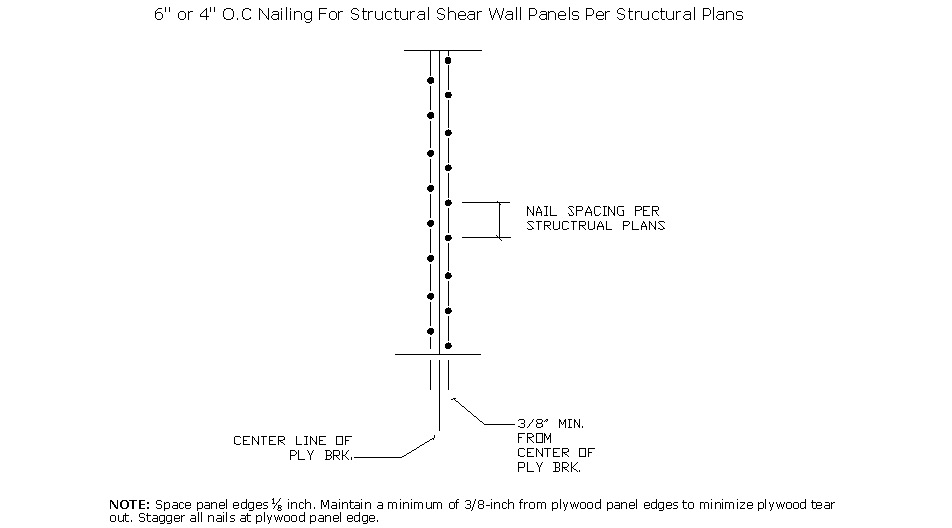

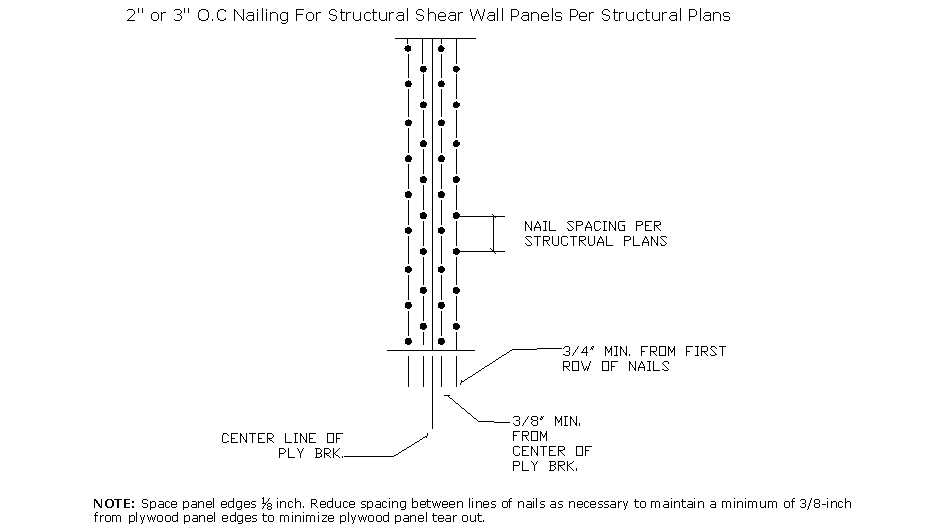

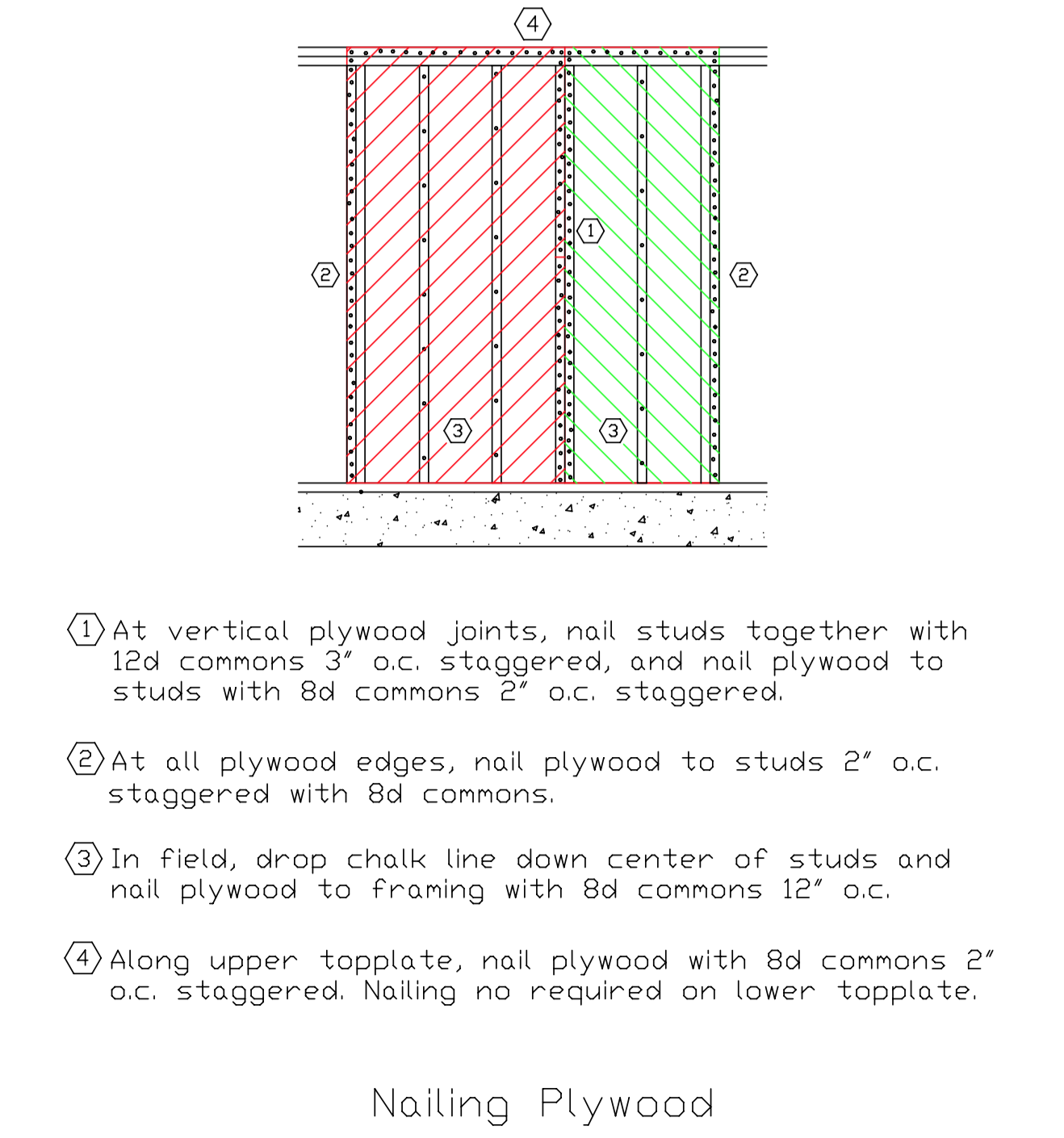

Shear Wall Nailing Pattern - Web develop a shear wall schedule using shear wall capacities defined in the american wood council’s 2021 special design provisions for wind and seismic. Web the shear wall schedule provided by the designer or engineer typically includes nail size and spacing. It will specify both edge nailing and field nailing. With overhead powerlines, a found. See table 6, page 14, for nail dimensions. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Web this installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. Shear walls are designed by an engineer to resist the specific forces determined by engineering analysis. Web if our design did not have enough capacity to support the shear wall force, we could modify the sheathing and nailing to increase that strength. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. It will specify both edge nailing and field nailing. The final passing design has studs. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center. A diaphragm structure results when a series of such. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web the construction documents for each project should clearly indicate the diameter and length of the nails to use for each shear wall, as well as the spacing of the fasteners around. The final. Web relationship between the ultimate capacities of a shear wall when tested monotonically versus the ultimate capacity of that same shear wall tested under cyclic loading. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Asked oct 10,. Asked oct 10, 2021 at 0:30. Web the term “diaphragm” is usually applied to roofs and floors. Intersections (no hold downs) typical shear wall. Web sheathing and nail pattern in clearcalcs, you can select your sheathing thickness for osb/plywood and nail pattern to choose the nail diameter and spacing. Web the construction documents for each project should clearly indicate the. Web sheathing and nail pattern in clearcalcs, you can select your sheathing thickness for osb/plywood and nail pattern to choose the nail diameter and spacing. See table 6, page 14, for nail dimensions. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web this installation manual covers basic installation recommendations for zip. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web develop a shear wall schedule using shear wall capacities defined in the american wood council’s 2021 special design provisions for wind and seismic. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on. Web develop a shear wall schedule using shear wall capacities defined in the american wood council’s 2021 special design provisions for wind and seismic. It will specify both edge nailing and field nailing. A diaphragm structure results when a series of such. Web sheathing and nail pattern in clearcalcs, you can select your sheathing thickness for osb/plywood and nail pattern. Intersections (with hold downs) 2x top plate splice The final passing design has studs. See table 6, page 14, for nail dimensions. Web relationship between the ultimate capacities of a shear wall when tested monotonically versus the ultimate capacity of that same shear wall tested under cyclic loading. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot. The final passing design has studs. Web typical wood structural panel nailing typical shear wall. Web relationship between the ultimate capacities of a shear wall when tested monotonically versus the ultimate capacity of that same shear wall tested under cyclic loading. Shear walls are designed by an engineer to resist the specific forces determined by engineering analysis. A diaphragm structure. Web if our design did not have enough capacity to support the shear wall force, we could modify the sheathing and nailing to increase that strength. A diaphragm structure results when a series of such. Web relationship between the ultimate capacities of a shear wall when tested monotonically versus the ultimate capacity of that same shear wall tested under cyclic. Intersections (with hold downs) 2x top plate splice Intersections (no hold downs) typical shear wall. A good shear wall starts with the studs, your wall studs need to be stuffed up a. The final passing design has studs. Web the shear wall schedule provided by the designer or engineer typically includes nail size and spacing. Web nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field. Web relationship between the ultimate capacities of a shear wall when tested monotonically versus the ultimate capacity of that same shear wall tested under cyclic loading. This tip sheet reflects code requirements of the 2018 international residential code (irc) with washington. See table 6, page 14, for nail dimensions. Web typical wood structural panel nailing typical shear wall. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Web develop a shear wall schedule using shear wall capacities defined in the american wood council’s 2021 special design provisions for wind and seismic. It will specify both edge nailing and field nailing. Nails for wall sheathing may be common, box or casing. Web the term “diaphragm” is usually applied to roofs and floors.

Shear Walls, The Basics JLC Online

Structural Shear Wall Nailing in Commercial and Residential Framing

20+ Shear Wall Nailing Pattern IdenSaukin

Shear Walls Nails Patterns, Liquid Flashing, Sheathing Everything 13

8 Tips and Tricks on Effective Shear Wall Construction

Structural Shear Wall Nailing in Commercial and Residential Framing

Shear Walls, The Basics JLC Online

8 Tips and Tricks on Effective Shear Wall Construction

20+ Shear Wall Nailing Pattern IdenSaukin

Plywood Sheathing Nailing Pattern Nail Ftempo

Web Fasteners Shall Be Placed In A Grid Pattern Throughout The Body Of The Panel.

Web The Construction Documents For Each Project Should Clearly Indicate The Diameter And Length Of The Nails To Use For Each Shear Wall, As Well As The Spacing Of The Fasteners Around.

With Overhead Powerlines, A Found.

Web This Installation Manual Covers Basic Installation Recommendations For Zip System Sheathing When Used In Both Roof And Wall Applications.

Related Post: