Shear Wall Nail Pattern

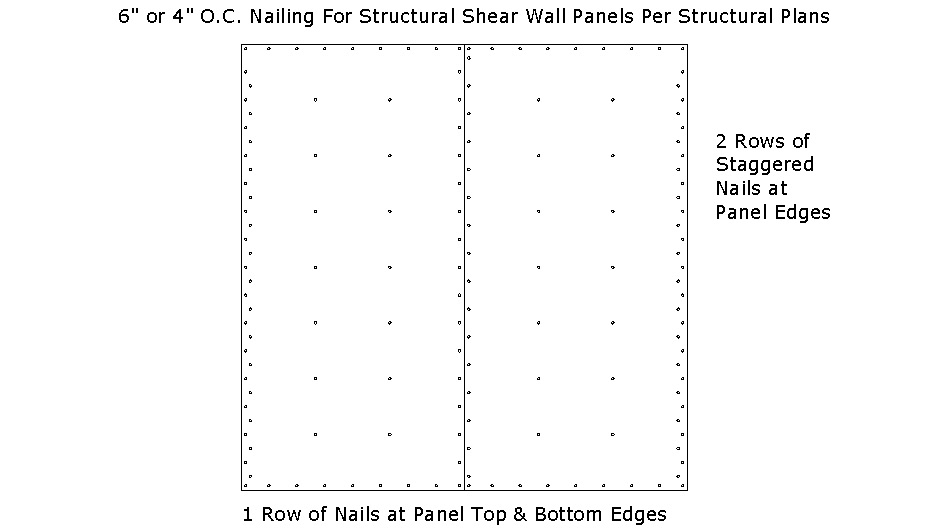

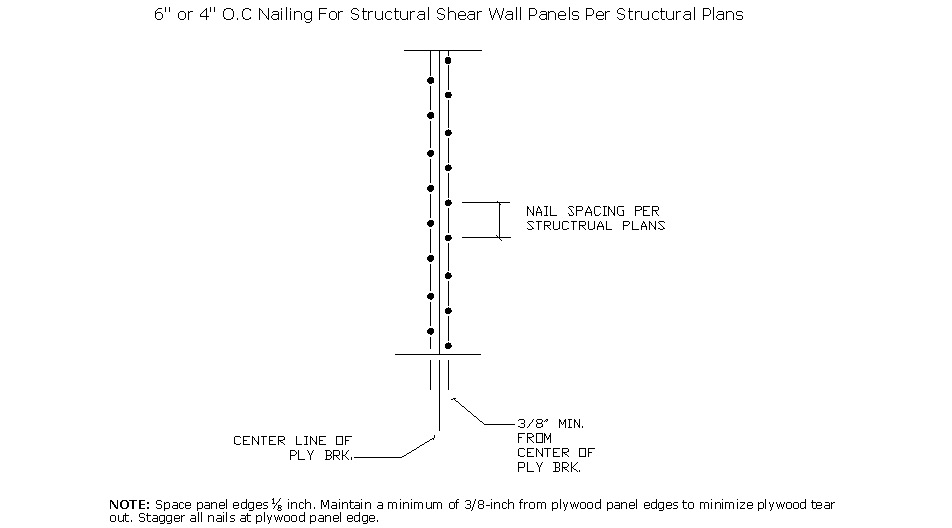

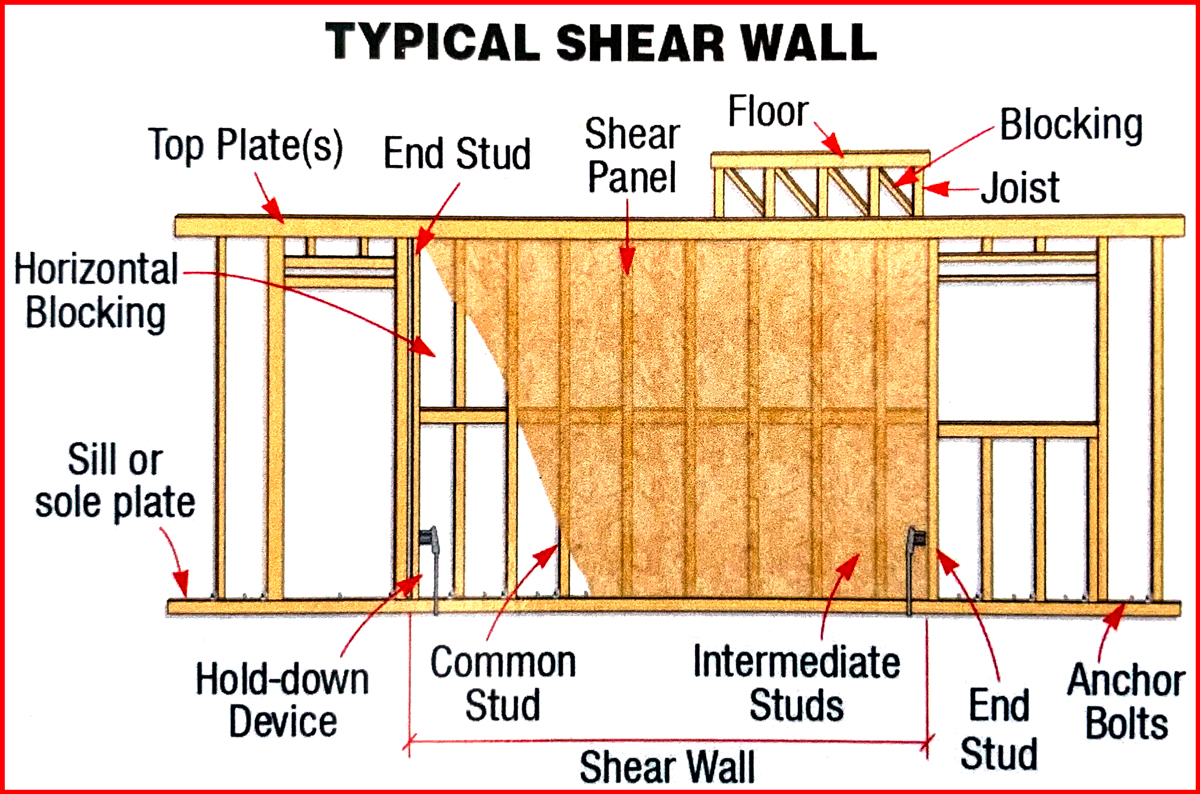

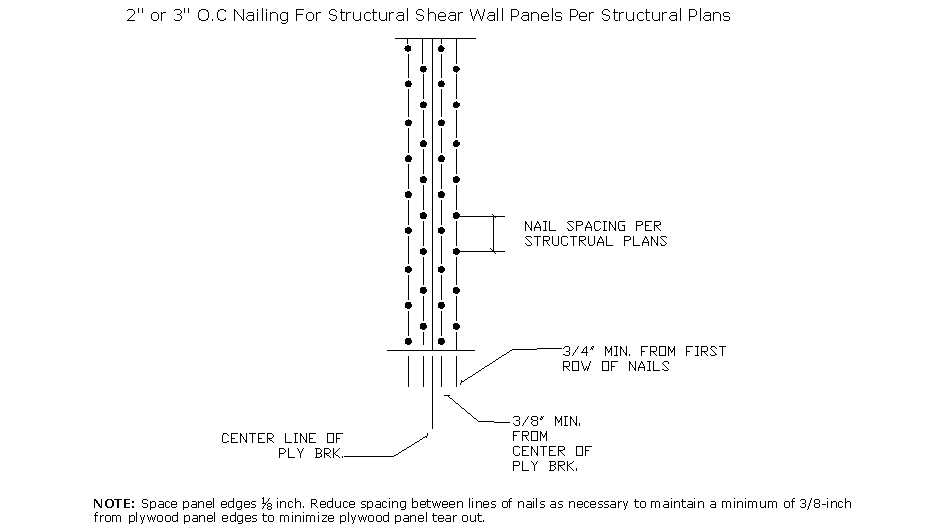

Shear Wall Nail Pattern - Nails used for framing and sheathing connections shall have minimum average bending yield strengths as shown: Wood structural panel wall bracing and shear walls wood structural panel wall bracing and shear walls are used to resist racking forces caused by lateral loads from wind or seismic events. Web pacity of diaphragms and shear walls shall be permitted. Web correct fasteners and nailing pattern for structural wall sheathing. The sheathing, along with the nails & spacing, are what govern the shear capacity of the. Shear walls using gypsum wallboard are subject to the following limits (underlines show clarifying. Develop a shear wall schedule using shear wall capacities defined in the american wood ouncil’s 2021 special design provisions for wind and seismic (sdpws). Web if our design did not have enough capacity to support the shear wall force, we could modify the sheathing and nailing to increase that strength. Intersections (with hold downs) 2x top plate splice 1)start out by distributing the shear to walls in the same line based on their lengths. In clearcalcs, you can select your sheathing thickness for osb/plywood and nail pattern to choose the nail diameter and spacing. Web the shear wall calculator has 3 main sections 1. Use 7/16 osb with a 6:12 nailing pattern which has an allowable load of 336 plf. Here (above right), 3/12 refers to edge and. Web if our design did not. If 6 inches, nail them 6 inches apart, etc. A diaphragm structure results when a series of such vertical and horizontal diaphragms are properly tied together to form a structural unit. Summary key properties sheathing and nail pattern. Shear walls using gypsum wallboard are subject to the following limits (underlines show clarifying. Shear wall aspect ratio adjustments were revised to. Intersections (no hold downs) typical shear wall. At a minimum, i recommend pairs of 16d nails every 12 inches along the beam, with the top row of nails 1 1/2 inches or so from the top of the beam, and the bottom row 1 1/2 inches or so up from the bottom. Web the bottom line, though, is that if. Develop a shear wall schedule using shear wall capacities defined in the american wood ouncil’s 2021 special design provisions for wind and seismic (sdpws). Walls continuously sheathed in plywood or osb also provide an excellent nail base for brick ties, siding and trim. If the plywood nailing is going to be 2 inches apart, nail them together 2 inches apart. Slip and panel shear deformation, kips/in. See table 6, page 14, for nail dimensions. The nails were spaced precisely at 6 o.c. Shear walls designed according to the. Web the bottom line, though, is that if all the pieces deflect together and equally, the beam should perform as designed. (12.2 m by 2.4 m) walls were tested; See table 24 for wall sheathing recommendations under exterior stucco finishes. Intersections (with hold downs) 2x top plate splice 2 rows of staggered nails at panel edges. Nailing for structural shear wall panels per structural plans. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. Web the bottom line, though, is that if all the pieces deflect together and equally, the beam should perform as designed. 1)start out by distributing the shear to walls in the same line based on their lengths.. Slip and panel shear deformation, kips/in. In the field because sbcri staff marked the fastener locations on the panel. (from column a, tables 4.2a, 4.2b, 4.2c, or. Web 2 or 3 o.c. Wood structural panel wall bracing and shear walls wood structural panel wall bracing and shear walls are used to resist racking forces caused by lateral loads from wind. We use consistent shear panels and nailing for all walls in one line. Ratioa = lengtha / sum (lengths in the line). Shear walls designed according to the. What is the best way to orient the plywood for the best shear strength and nail retention? In typical construction, siding, trim and brick ties are attached to framing members. To be calculated by principles of mechanics using va. See table 24 for wall sheathing recommendations under exterior stucco finishes. Use 7/16 osb with a 6:12 nailing pattern which has an allowable load of 336 plf. In the field because sbcri staff marked the fastener locations on the panel. A diaphragm structure results when a series of such vertical and. Web typical wood structural panel nailing typical shear wall. Web the wall framing consisted of spf studs spaced 16 o.c. To be calculated by principles of mechanics using va. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. Web correct fasteners and nailing pattern for structural wall sheathing. If the plywood nailing is going to be 2 inches apart, nail them together 2 inches apart with 16’s. 2 rows of staggered nails at panel edges. Shear walls designed according to the. Use 7/16 osb with a 4:12 nailing pattern which has an allowable load of 490 plf. Stagger all nails at plywood panel edge. Nails used for framing and sheathing connections shall have minimum average bending yield strengths as shown: Web the bottom line, though, is that if all the pieces deflect together and equally, the beam should perform as designed. = apparent diaphragm shear stiffness from nail. Along the panel edges and 12 o.c. As well, we have a 7/16” osb sheathing and a nail pattern of 8 diameter nails at 6” spacing. See table 6, page 17, for nail dimensions.

Structural Shear Wall Nailing in Commercial and Residential Framing

Wood Shear Walls Structural engineering general discussion EngTips

Structural Shear Wall Nailing in Commercial and Residential Framing

Shear Walls, The Basics JLC Online

Shear Walls What are they? Lynn Engineering

Shear Walls, The Basics JLC Online

8 Tips and Tricks on Effective Shear Wall Construction

8 Tips and Tricks on Effective Shear Wall Construction

Shear Walls Nails Patterns, Liquid Flashing, Sheathing Everything 13

Structural Shear Wall Nailing in Commercial and Residential Framing

1 Row Of Staggered Nails At Panel Top & Bottom Edges.

We Use Consistent Shear Panels And Nailing For All Walls In One Line.

In Typical Construction, Siding, Trim And Brick Ties Are Attached To Framing Members.

Slip And Panel Shear Deformation, Kips/In.

Related Post: