Sand Casting Pattern

Sand Casting Pattern - Web the pattern material is chosen based on the casting volume and process used. A pattern, which is a replica of the desired casting, is created in the. Web below, you’ll learn more about the six primary steps of sand casting. The split pattern shown with cutaway of flask. Web the printed pattern is then packed with sand and removed from the mold. Web sand casting steps. Web sand casting equipment within a foundry can be very basic or quite advanced, depending on the items being made. Incorporate the pattern and sand in a gating system. Wood and metal patterns are usually used with sand casting, while wax is rarely used for anything but investment casting. Experienced journeyman sand casting patternmakers. This mold requires features related to gas venting, fill and thermal compensation volumes, and core support, and it can then be filled with molten metal, which cools in place to. Experienced journeyman sand casting patternmakers. It is a versatile and widely used casting method that can produce complex shapes and accommodate various metal alloys. A sand casting pattern can be. These are typically made of sand, clay, or coal. The working principle of sand casting is relatively simple. Web these patterns are used to create an impression in the sand mold. Web the printed pattern is then packed with sand and removed from the mold. They are used to create internal spaces, such as holes, passages, and cavities within the. Patterns vary in complexity, depending on the size, shape, and number of resulting castings required. Web the topics of this class are:patterns and coresa. Web sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a part to be copied/reproduced). Wood and metal patterns are usually used with sand. The working principle of sand casting is relatively simple. The sand casting process doesn’t start with the sand. The two halves of the mold are aligned and joined together. The term sand casting can also refer to an object produced via the sand casting process. Web pattern (casting) the top and bottom halves of a sand casting mould showing the. Web here are the five basic sand casting process steps. Web a replica pattern is used to create a mold out of rubber, metal, or resin. In the sand casting foundry (whichever cast iron casting , aluminum casting or steel casting), a pattern set includes pattern, gating system feefer head, riser and pattern plate. The process begins with a pattern.. Web what is the sand casting process? Typical materials used include wood, plaster, plastic and metal, but if the pattern calls for specific properties, other materials may be used instead. After the shell mold has completely cured, the cast. Mold patterns, including sand casting patterns, come in a variety of styles for making simple or complex, solid or hollow objects.. Web some castings need one or multiple cores. The mold cavity is inspected for any defects or irregularities. Step #1) place mold pattern in sand. They are used to create internal spaces, such as holes, passages, and cavities within the casting. This mold requires features related to gas venting, fill and thermal compensation volumes, and core support, and it can. Web the pattern material is chosen based on the casting volume and process used. Web a replica pattern is used to create a mold out of rubber, metal, or resin. Web sand casting is a metal casting process that uses sand as the primary molding material. Web sand casting equipment within a foundry can be very basic or quite advanced,. Mold patterns, including sand casting patterns, come in a variety of styles for making simple or complex, solid or hollow objects. The mold cavity is inspected for any defects or irregularities. Web here are the five basic sand casting process steps. Web the topics of this class are:patterns and coresa. The first step in the sand casting process is to. Typical materials used include wood, plaster, plastic and metal, but if the pattern calls for specific properties, other materials may be used instead. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Precision cnc wood and urethane pattern construction. The sand is packed around the pattern in. They are used to create internal spaces, such as holes, passages, and cavities within the casting. The two halves of the split pattern nest together. Excess sand is removed by a process known. Web in sand casting, the split pattern enables the mold to be opened and closed, making the process efficient for producing a variety of shapes and sizes. Web the casting patterns are used to press into the sand mold to create the hollow cavity that allowing molten metal to be poured into and forming the casting. Web sand casting steps. Trying to sculpt a mold freeform probably wouldn’t be terribly, well, precise. Experienced journeyman sand casting patternmakers. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. In casting, a pattern is a replica of the object to be cast, used to form the sand mould. Web the sand casting process involves creating a mold using a pattern, pouring molten metal into the mold, cooling and solidifying the metal, and then removing the casting from the mold. Web sand casting works by generating a mold by forming a packed sand body around a wooden or rapid prototype master/pattern (or a part to be copied/reproduced). Web sand casting flask, mold, patterns, and core. The sand is packed around the pattern in a wooden or metal box called a flask. The number of castings and the required. In the sand casting foundry (whichever cast iron casting , aluminum casting or steel casting), a pattern set includes pattern, gating system feefer head, riser and pattern plate.

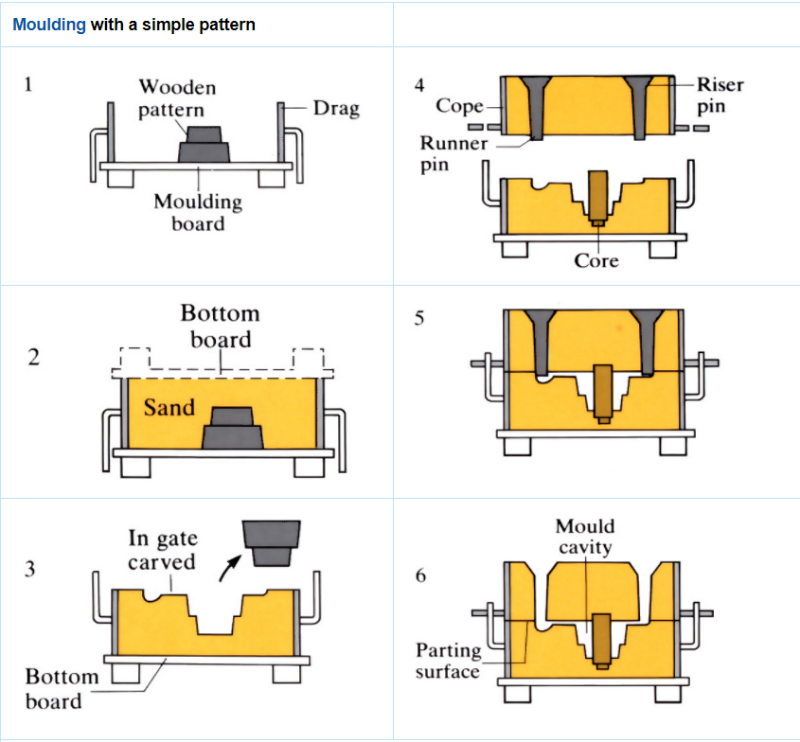

A 101 Guide to Sand Casting

Sand Casting

Types of Pattern in Sand Casting (3D Animation) YouTube

Patterns and Cores Sand Casting. YouTube

Sand Casting Services Austral Brass Foundry

Sand casting OpenLearn Open University

Sand Casting Pattern at best price in Pune by Edgecon Technologies ID

Large Open Heart Sand Casting Pattern DIY Castings

The 6Step Process of Sand Casting Molding OneMonroe

Sand Casting Patterns Forte Tool & Die

It Is A Versatile And Widely Used Casting Method That Can Produce Complex Shapes And Accommodate Various Metal Alloys.

The Working Principle Of Sand Casting Is Relatively Simple.

Here, A Split Pattern Is Used.

These Are Typically Made Of Sand, Clay, Or Coal.

Related Post: