Roof Shingle Nailing Pattern

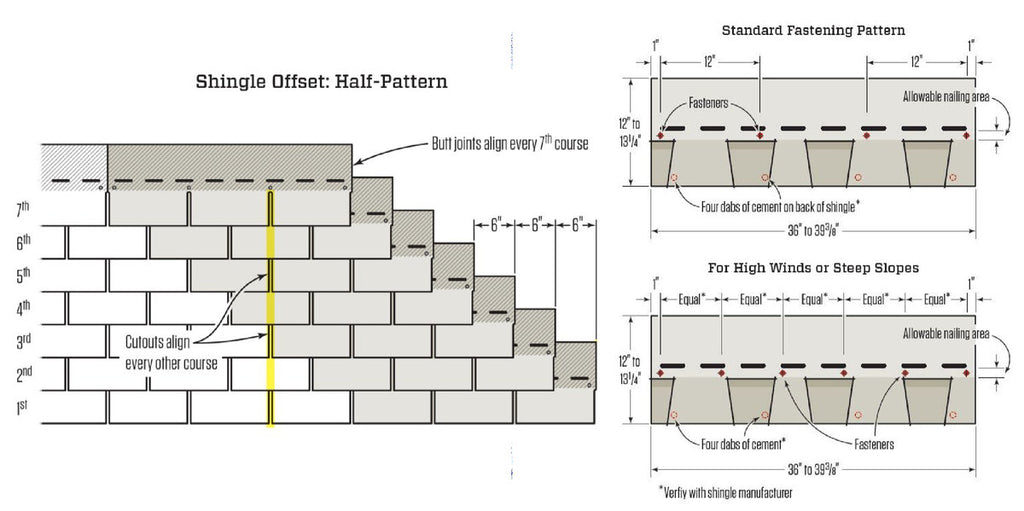

Roof Shingle Nailing Pattern - Look out for underdriven, overdriven, or angled nails during installation to reduce the risk of installation issues. With the increased size and visibility of the nailing area, workers were able to fasten the. Web strike nails at a 90 degree angle from the roof when hammering by hand. For best appearance, use heavier weight shingles, or laminated or textured shingles. So, your next course of shingles should cover the nails by 1 inch vertically. If you are using a power nailer, drive nails by squeezing the trigger and bouncing the nailer's tip onto the shingle. Hammer one nail about 2 inches from each end of a shingle. Asphalt roofing cement should meet astm d 4586 type ii. Then secure another nail an inch above each cutout. Properly fastened shingles resist both high wind uplift damage as well as “slipping” which can occur when a very steep roof is fastened inadequately and gravity pulls the roof shingle out of place causing the. If you are using a power nailer, drive nails by squeezing the trigger and bouncing the nailer's tip onto the shingle. Nails must not be exposed (visible) on the finished roof. Mark 12 inches up on the roof for the first course of shingles. You want them away from the middle of each individual shingle. If using asphalt or fiberglass. Look out for underdriven, overdriven, or angled nails during installation to reduce the risk of installation issues. The lower the gauge number, the thicker the nail. Fasten with two (2) nails, one (1) on each side, 3⁄4 (19 mm) behind the cutout and 1⁄2 (13 mm) up from the side. So, your next course of shingles should cover the nails. With the increased size and visibility of the nailing area, workers were able to fasten the. The strikezone nailing area is so easy to hit that a roofer placed. Another disadvantage of racking a roof is the zipper appearance that the pattern can display in the finished roof. Use 5 fasteners for each shingle, placed 2 to 3 inches up. Use 5 fasteners for each shingle, placed 2 to 3 inches up from eaves edge. The lower the gauge number, the thicker the nail. Web included below is a copy of iko’s nailing instructions found on each package of iko three tab shingles. Properly fastened shingles resist both high wind uplift damage as well as “slipping” which can occur when. Properly fastened shingles resist both high wind uplift damage as well as “slipping” which can occur when a very steep roof is fastened inadequately and gravity pulls the roof shingle out of place causing the. Obviously, the roof nails are intended to hold the roof shingle in place during all weather and temperature conditions. Continue each course across the roof. Web push down on the center of the shingle and adjust to fit the pitch of roof. Fasten with two (2) nails, one (1) on each side, 3⁄4 (19 mm) behind the cutout and 1⁄2 (13 mm) up from the side. Install the second, third and fourth courses: If you are using a power nailer, drive nails by squeezing the. Steep slope use six nails and four spots of asphalt roofing cement for every full shingle for every full shingle as shown below. Web use an owens corning® starter product. This chapter will demonstrate how to properly nail. You want them away from the middle of each individual shingle. Web included below is a copy of iko’s nailing instructions found. The strikezone nailing area is so easy to hit that a roofer placed. This chapter will demonstrate how to properly nail. With the increased size and visibility of the nailing area, workers were able to fasten the. Web the bad habit of skipping one fastener on every other shingle is called “cheat nailing,” which can lead to shingle drooping (where. Web push down on the center of the shingle and adjust to fit the pitch of roof. These shingles must be installed in a specific way to always yield the hexagonal pattern. So, your next course of shingles should cover the nails by 1 inch vertically. Always adjust nail guns appropriately to avoid improper fastener installation. Steep slope use six. Web all nails must be driven straight with the heads flush to the shingle surface, never cutting into the shingle. Another disadvantage of racking a roof is the zipper appearance that the pattern can display in the finished roof. This will provide time for roof sheathing to adjust to humidity and moisture conditions. These shingles must be installed in a. Hammer one nail about 2 inches from each end of a shingle. Always adjust nail guns appropriately to avoid improper fastener installation. When nailing shingles, proper penetration into the roof deck is essential to ensure the nail and shingle remain secure. Install shingles according to manufacturer's recommendations. With the increased size and visibility of the nailing area, workers were able to fasten the. The strikezone nailing area is so easy to hit that a roofer placed. Iko armourshield shingles from europe offer a distinctive hexagonal shape, and also incorporate a shadow band for additional depth aesthetics. For best appearance, use heavier weight shingles, or laminated or textured shingles. Web included below is a copy of iko’s nailing instructions found on each package of iko three tab shingles. So, your next course of shingles should cover the nails by 1 inch vertically. That ensures the gap in the shingle. Note that the nails are just below the tar line. Typical roofing nails may have a smooth or circular unconnected rings around the body to help them maintain grip in the deck. Use galvanized (zinc coated) roofing nails, 11 or 12 gauge, with at least 3/8 diameter heads, long enough to penetrate through plywood or 3/4 into boards. Fasten with two (2) nails, one (1) on each side, 3⁄4 (19 mm) behind the cutout and 1⁄2 (13 mm) up from the side. As you continue, follow the pattern of lining a full shingle up against the next and then nailing it into place.

Seaside Heights Roofers How to properly nailinstall GAF Timberline

How to Install Roof Shingles HireRush Blog

A Guide to Roofing Nails for Shingles Nail Sizes & Types IKO

Nailing Pattern For Architectural Shingles Nail Ftempo

Roof Shingle LayOut And Nailing Patterns

Nailing Pattern For Architectural Shingles Nail Ftempo

Proper Nailing Pattern For Architectural Shingles Nail Ftempo

Roof Shingle LayOut and Nailing Patterns GutterBrush

The standard nailing for asphalt shingles is a fournail pattern, with

Shingle Nailing Pattern McToolman

Mark 12 Inches Up On The Roof For The First Course Of Shingles.

To Lay Out The Design For The Shingles, Begin At The Bottom Of The Roof And Place A Tape Measure ½ Inch From The Edge Of The Roof To Ensure The Shingles Overhang The Drip Edge.

If Using Asphalt Or Fiberglass Shingles, Postpone Shingle Installation As Long As Possible.

Steep Slope Use Six Nails And Four Spots Of Asphalt Roofing Cement For Every Full Shingle For Every Full Shingle As Shown Below.

Related Post: