Roof Shingle Nail Pattern

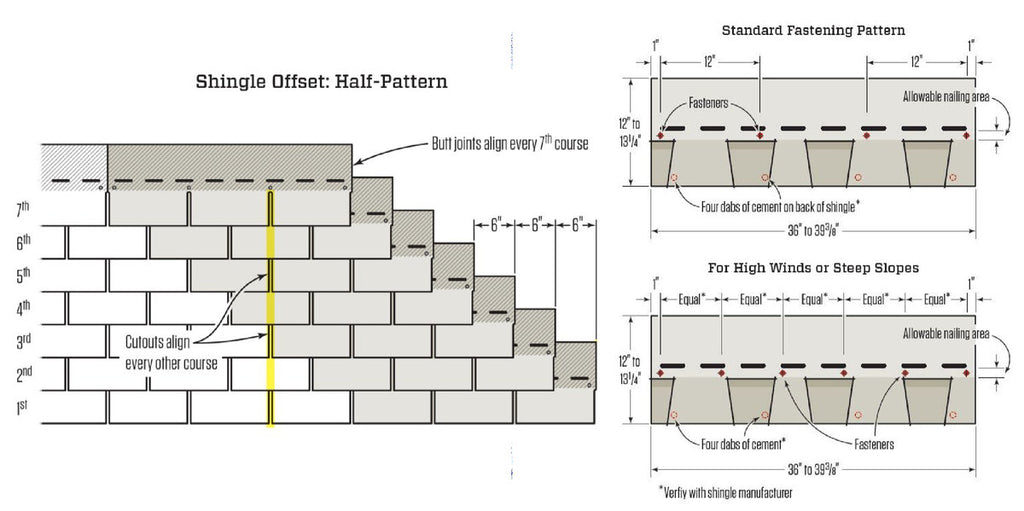

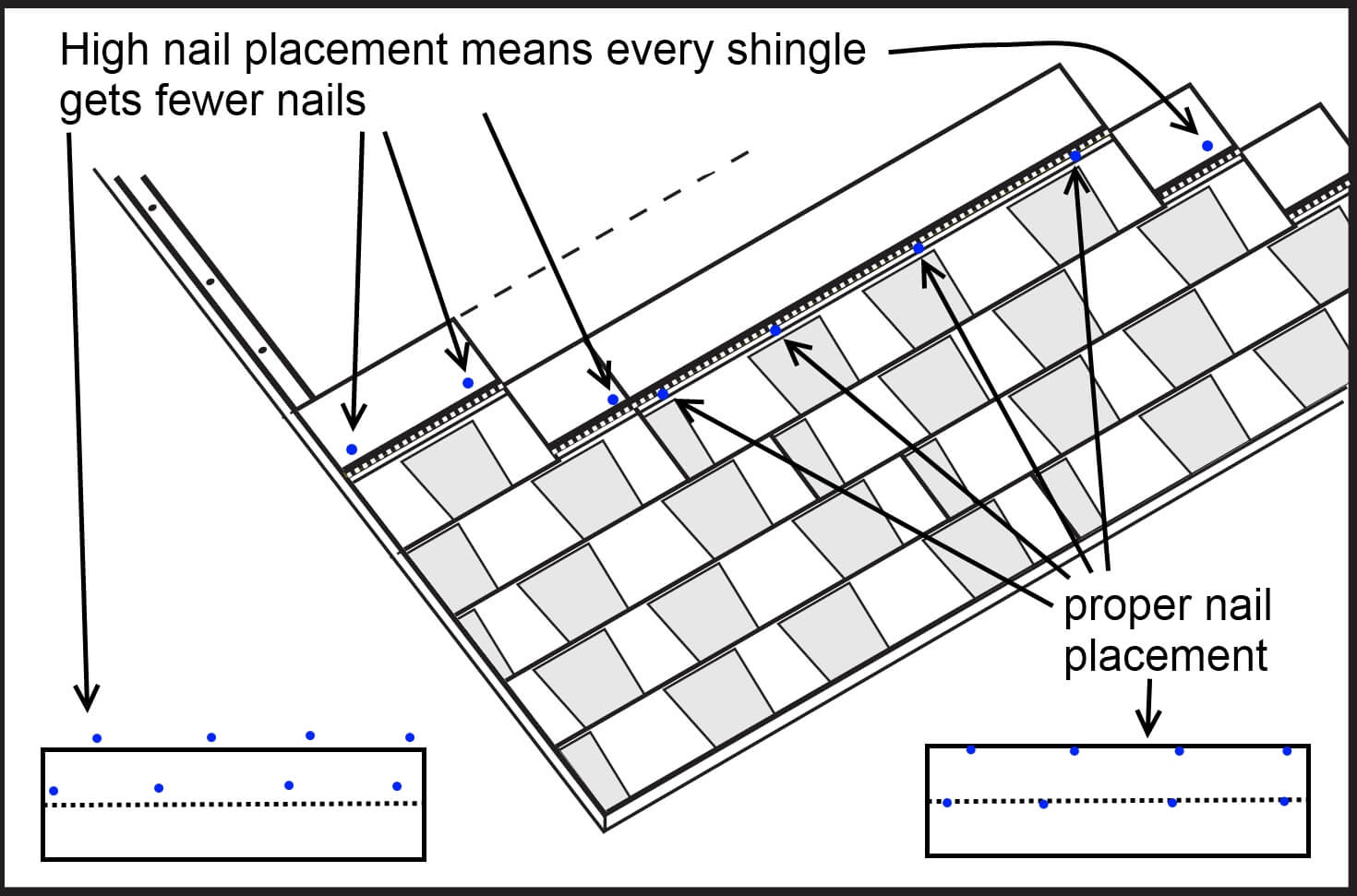

Roof Shingle Nail Pattern - Web included below is a copy of iko’s nailing instructions found on each package of iko three tab shingles. Web the bad habit of skipping one fastener on every other shingle is called “cheat nailing,” which can lead to shingle drooping (where one end of the shingle slips downward) and blowoffs. Web push down on the center of the shingle and adjust to fit the pitch of roof. Nails must not be exposed (visible) on the finished roof. Fasteners should be 3/8 inch from panel ends and 3/8 inch from panel. Keep your nails on either side of the gap. Obviously, the roof nails are intended to hold the roof shingle in place during all weather and temperature conditions. As you continue, follow the pattern of lining a full shingle up against the next and then nailing it into place. [2] cut six inches off the length of the first starter shingle nailed on, then use the rest of them full size. This row should peek over the eaves by about a half inch (1.3 centimeters). Web all nails must be driven straight with the heads flush to the shingle surface, never cutting into the shingle. With the increased size and visibility of the nailing area, workers were able to fasten the. Use 5 fasteners for each shingle, placed 2 to 3 inches up from eaves edge. Web push down on the center of the shingle. These shingles must be installed in a specific way to always yield the hexagonal pattern. The strikezone nailing area is so easy to hit that a. The lower the gauge number, the thicker the nail. Continue each course across the roof with full shingles butting ends loosely. [2] cut six inches off the length of the first starter shingle nailed. Use galvanized (zinc coated) roofing nails, 11 or 12 gauge, with at least 3/8 diameter heads, long enough to penetrate through plywood or 3/4 into boards. Web push down on the center of the shingle and adjust to fit the pitch of roof. Web included below is a copy of iko’s nailing instructions found on each package of iko three. Install the second, third and fourth courses: Steep slope use six nails and four spots of asphalt roofing cement for every full shingle for every full shingle as shown below. This chapter will demonstrate how to properly nail. Ring shank nails have connected rings. Web in a test performed at home innovations research lab, an independent lab in maryland, a. The lower the gauge number, the thicker the nail. Another disadvantage of racking a roof is the zipper appearance that the pattern can display in the finished roof. Keep your nails on either side of the gap. Properly fastened shingles resist both high wind uplift damage as well as “slipping” which can occur when a very steep roof is fastened. The strikezone™ nailing area provides an up to 600% larger nailing target¹ for improved accuracy, and up to 30% faster nail fastening.² by nailing in the strikezone nailing area, nails pass through two courses of shingles for secondary fastening. Ring shank nails have connected rings. Asphalt roofing cement should meet astm d 4586 type ii. Web all nails must be. Asphalt roofing cement should meet astm d 4586 type ii. Web included below is a copy of iko’s nailing instructions found on each package of iko three tab shingles. Fasten with two (2) nails, one (1) on each side, 3⁄4 (19 mm) behind the cutout and 1⁄2 (13 mm) up from the side. [2] cut six inches off the length. Continue each course across the roof with full shingles butting ends loosely. So, your next course of shingles should cover the nails by 1 inch vertically. Web included below is a copy of iko’s nailing instructions found on each package of iko three tab shingles. The strikezone nailing area is so easy to hit that a. Use 5 fasteners for. Trim off 10″, 20″, and 30″ respectively, from the left end of the starting shingle and apply to overhang rake edge by 1/4″ to 3/4″. Keep your nails on either side of the gap. Lay the first row of shingles directly covering the narrow starter row. Fasteners should be 3/8 inch from panel ends and 3/8 inch from panel. With. The strikezone™ nailing area provides an up to 600% larger nailing target¹ for improved accuracy, and up to 30% faster nail fastening.² by nailing in the strikezone nailing area, nails pass through two courses of shingles for secondary fastening. Web when nailing shingles, roofers mostly choose from among these four common types of roofing nail: You want them away from. Nails must not be exposed (visible) on the finished roof. Obviously, the roof nails are intended to hold the roof shingle in place during all weather and temperature conditions. Drive a nail at one end first, then drive the others. Asphalt roofing cement should meet astm d 4586 type ii. Ring shank nails have connected rings. The strikezone nailing area is so easy to hit that a. Steep slope use six nails and four spots of asphalt roofing cement for every full shingle for every full shingle as shown below. Properly fastened shingles resist both high wind uplift damage as well as “slipping” which can occur when a very steep roof is fastened inadequately and gravity pulls the roof shingle out of place causing the. Another disadvantage of racking a roof is the zipper appearance that the pattern can display in the finished roof. Use 5 fasteners for each shingle, placed 2 to 3 inches up from eaves edge. At intermediate supports, fasten panels 12 inches on center. Keep your nails on either side of the gap. Web when nailing shingles, roofers mostly choose from among these four common types of roofing nail: Install the second, third and fourth courses: Use galvanized (zinc coated) roofing nails, 11 or 12 gauge, with at least 3/8 diameter heads, long enough to penetrate through plywood or 3/4 into boards. As you continue, follow the pattern of lining a full shingle up against the next and then nailing it into place.

Roof Shingle LayOut and Nailing Patterns GutterBrush

Improper shingle nailing Structure Tech Home Inspections

Shingle Nailing Pattern McToolman

Improper Shingle Nailing

The standard nailing for asphalt shingles is a fournail pattern, with

HOW TO INSTALL 6 NAILS PER SHINGLE YouTube

Seaside Heights Roofers How to properly nailinstall GAF Timberline

How to Shingle a Shed With 3 Tab and Architectural Shingles

Asphalt Roof Shingling Basics JLC Online

Roof Shingle LayOut and Nailing Patterns GutterBrush

Web All Nails Must Be Driven Straight With The Heads Flush To The Shingle Surface, Never Cutting Into The Shingle.

You Want Them Away From The Middle Of Each Individual Shingle.

Fasten With Two (2) Nails, One (1) On Each Side, 3⁄4 (19 Mm) Behind The Cutout And 1⁄2 (13 Mm) Up From The Side.

Note That The Nails Are Just Below The Tar Line.

Related Post: