Rolling Asphalt Patterns

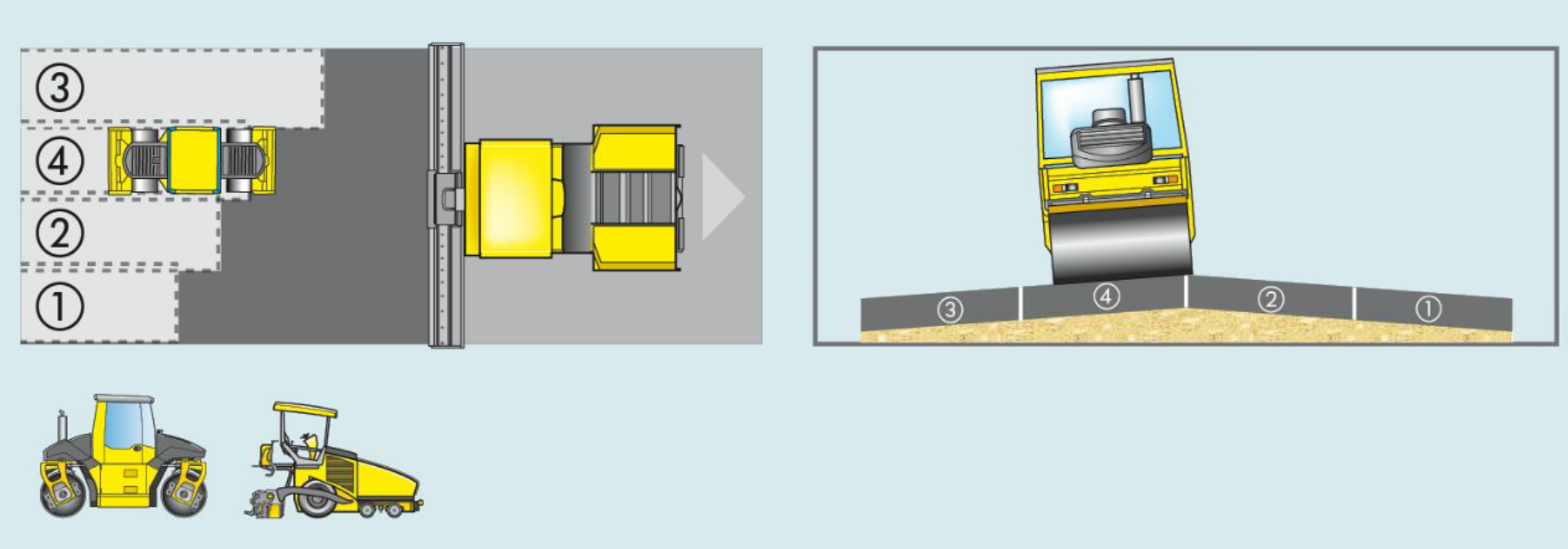

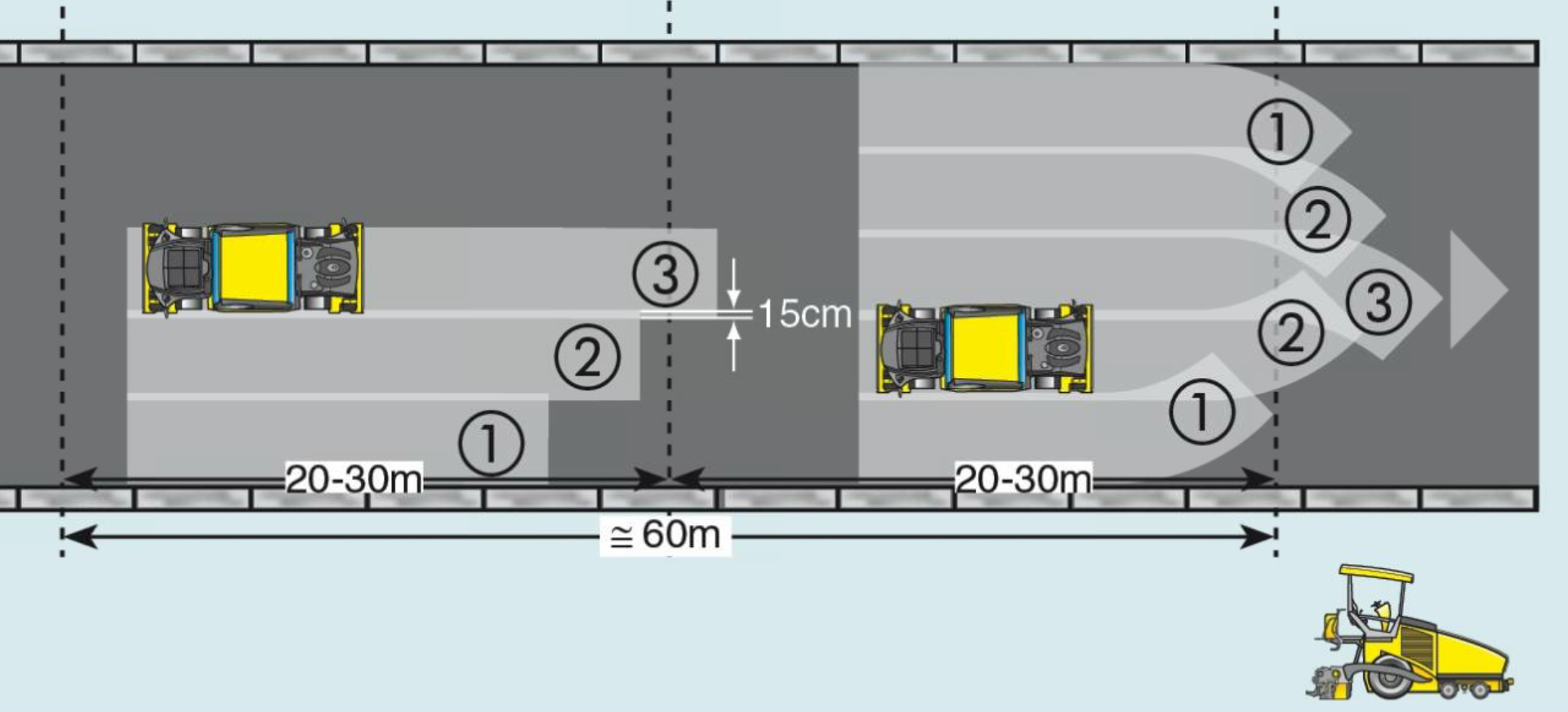

Rolling Asphalt Patterns - If the paver is going too fast, density may only be in the. Web the xpactor can assist learning with any number of compaction issues including proper rolling patterns, longitudinal joint rolling and time available for compaction. Typically, asphalt comes out of the plant at about 300° f. Web asphalt concrete mixtures cool quickly so it’s important to compact while the mix is hot. Web rolling pattern •speed and lap pattern for each roller •number of passes for each roller •one trip across a point on the mat •set minimum temperature each roller finishes important: It works immediately behind the paver where the asphalt is the hottest and it must match the production and speed of the. •paver speed must not exceed compaction!!! Web how to roll hot asphalt. On some states like maine,the rolling patterns are the following,either vibratory or static steel wheel rollers for breakdown rolling,pneumatic (rubber tired) roller for intermediate rollers and either vibratory or static steel wheel rollers for finish rolling.for example,hypac c766d vibratory roller or hypac c350d static. The xpactor has been making the rounds at recent industry events including world of asphalt 2003 and the national asphalt pavement association's (napa) 2003. Web the xpactor can assist learning with any number of compaction issues including proper rolling patterns, longitudinal joint rolling and time available for compaction. Hot mix asphalt materials, mixture design, and construction. Stop forward motion of the compactor, rolling in a slight arc toward the center of the panel, a safe distance behind the paver and crew. First, you have. Your intermediate roller should follow immediately afterward, and you should use it to create the best density achievable. This rolling pattern provides quick. Rollers can be used where the mat is most receptive to compaction and avoided where the mat is susceptible to excessive shoving. During most paving operations, at the end of each production day or night, someone from. Roll the end of each subsequent pass beyond the end of the adjacent and previous pass. Typically, asphalt comes out of the plant at about 300° f. This rolling pattern provides quick. In the august issue, scherocman, a consulting engineer in pavement design and construction located in cincinnati, discussed the importance of compaction and the relationship. Establish an effective rolling. Use of rollers with driven front drums. On some states like maine,the rolling patterns are the following,either vibratory or static steel wheel rollers for breakdown rolling,pneumatic (rubber tired) roller for intermediate rollers and either vibratory or static steel wheel rollers for finish rolling.for example,hypac c766d vibratory roller or hypac c350d static. Dale starry october 8, 2007 midwest contractor. Web the. Hot mix asphalt materials, mixture design, and construction. The rolling pattern is intended to be consistently repeated in order to produce uniform density in the asphalt layer. Web feb 15, 2010. The rolling pattern covers a certain area. If the paver is going too fast, density may only be in the. First, you have the breakdown roller, which develops the majority of the density in an asphalt layer. Rollers can be used where the mat is most receptive to compaction and avoided where the mat is susceptible to excessive shoving. Web txapa's industry relations consultants larry welch and chuck fuller lead a discussion on best practices for compaction and rolling patterns.check. Use of rollers with driven front drums. Web txapa's industry relations consultants larry welch and chuck fuller lead a discussion on best practices for compaction and rolling patterns.check out our ful. If the paver is going too fast, density may only be in the. It works immediately behind the paver where the asphalt is the hottest and it must match. This rolling pattern provides quick. Precision paving begins with proper equipment setup. Web a jelly roll is a bundle of 2.5″ wide strips of precut cotton quilt fabric that helps you sew a strip quilt in almost no time. Web stay tuned for the final installment in the precision asphalt paving 101 series, which will cover best practices for rolling. Make sure that your breakdown roller follows the paver’s speed, and always start at the outside edge of your lane. This rolling pattern provides quick. These density levels should be in the mid 70s to low 80s. •paver speed must not exceed compaction!!! Precision paving begins with proper equipment setup. The rolling pattern covers a certain area. Waiting one or more years after. Let’s say that takes three minutes. •paver speed must not exceed compaction!!! Web best practices of asphalt compaction. Make the first pass toward the paver with vibration on. Your intermediate roller should follow immediately afterward, and you should use it to create the best density achievable. Web it contains explanations to the different rolling patterns and a number of basic rules and notes for successful compaction of rolled asphalt. First, you have the breakdown roller, which develops the majority of the density in an asphalt layer. The first roller ( red, on the left close behind the paver) compacts the left side of the mat with two passes (numbers 1 and 2) up and back in exactly the same position, hanging over the left. Web the xpactor can assist learning with any number of compaction issues including proper rolling patterns, longitudinal joint rolling and time available for compaction. Stop forward motion of the compactor, rolling in a slight arc toward the center of the panel, a safe distance behind the paver and crew. Web the rolling pattern you use directly affects the results of your compacting job. Waiting one or more years after. Web stay tuned for the final installment in the precision asphalt paving 101 series, which will cover best practices for rolling pattern, as well as safety considerations. Precision paving begins with proper equipment setup. The bomag asphalt compaction handbook should serve as source of information for practicians involved in pavement construction and facilitate the use of compaction equipment in asphalt construction. Web how to roll hot asphalt. Roll the end of each subsequent pass beyond the end of the adjacent and previous pass. Web based on this calculation rolling equipment and patterns can be employed to: This rolling pattern provides quick.

Asphalt Rolling Temperature Chart

PPT BEST PRACTICES for ASPHALT PAVING FIELD OPERATIONS PowerPoint

TXAPA Best Practices for Compaction and Rolling Patterns YouTube

Rolling and Compacting Asphalt Approachway YouTube

Asphalt laying and rolling pattern by STR and PTR YouTube

Proper rolling technique of the joint. Asphalt, Paving, Proper

AsphaltPro Magazine AsphaltPro Magazine How to Roll for Bonus, Part

Pin by Russell Snyder on Asphalt Paving Operations in California

AsphaltPro Magazine AsphaltPro Magazine How to Roll for Bonus, Part

48+ Free Asphalt Textures for Designers in 2021

Web Options Are Available For Asphalt Compactors To Help Operators Maintain Uniform Rolling Patterns.

Web Rolling Patterns To Achieve Density And Production.

Solid Fabric Jelly Rolls, Sold In Many Colors, Are Also.

The Rolling Pattern Used Directly Affects Compaction.

Related Post: