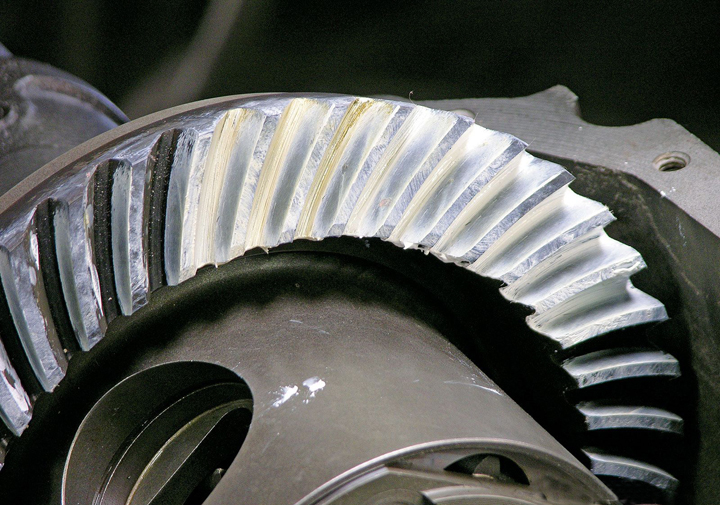

Ring And Pinion Pattern

Ring And Pinion Pattern - I am now in the process of setting up the gear pattern and shimming the pinion/carrier. Web published 27 march 2024. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. When changing pinion depth, make large changes until the pattern is close to ideal. Use something soft, like a small block of wood. Once the pinion gear is installed, position ring gear and carrier into housing to check backlash. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Web learn more about ring gear patterns in our “how to create & read ring gear patterns” article. Web gm 8.5 gear pattern. Toyota gear installs arizona by zuk. Swapping in 4.10's to my 8.5 10 bolt. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Web ring and pinion tooth contact patterns. Web i measured the pinion head to get my checking distance and used the ratech pinion tool. Web ring and pinion gear pattern is one of the most. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Use shims to move the ring gear farther from the pinion gear to increase backlash. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Swapping in 4.10's to. Rotate the pinion to turn the ring gear four complete revolutions on the drive side and then four in the opposite direction for the coast. Web see how to set up a ring and pinion gear set. I have a setup pinion bearing so it is easy for me to pull it apart and change shims. Web ring and pinion. Dialing in the tolerance between the gears will ensure a smooth. Web front axles, so use the drive side for reading the pattern. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web ring and pinion tooth contact patterns. I am setting up a gm 12 bolt. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Dialing in the tolerance between the gears will ensure a smooth. Earlier this month, a sudden atmospheric. Apply tooth contact compound to the ring gear in two places. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. The swirling ring of cold air is now spinning in the. Sequential graphic detail from too deep to to sha. Web ring and pinion pattern question. Web once preload is set install the seal and loctite pinion nut. Web all that said, you still need the correct tools for your axle. Web ring and pinion pattern question. The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. Web this will move the drive side. The pinion measured out at 1.890 and the tool shows 3.087. Web see how to set up a ring and pinion gear set. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. I am setting up a gm 12 bolt truck rear with. Use shims to move the ring gear closer to the pinion gear to decrease backlash. Web all that said, you still need the correct tools for your axle. Use something soft, like a small block of wood. This video was created to give people a basic understanding of. This will help give you a nice clear pattern like this one. Supply some drag on the ring gear while doing it. The pattern on the drive side is most important to. Web once preload is set install the seal and loctite pinion nut. The swirling ring of cold air is now spinning in the. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Web all that said, you still need the correct tools for your axle. Use shims to move the ring gear closer to the pinion gear to decrease backlash. I am setting up a gm 12 bolt truck rear with richmond 3:73 gears. Use shims to move the ring gear farther from the pinion gear to increase backlash. Supply some drag on the ring gear while doing it. Use something soft, like a small block of wood. 3) rotate the ring gear in both directions over the painted areas using the pinion yoke to spin it. (4) thinner pinion position shim with the backlash constant moves the pinion further from the ring gear. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Carefully apply moderate pressure to the outside ring gear. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. When changing pinion depth, make large changes until the pattern is close to ideal. Dialing in the tolerance between the gears will ensure a smooth. Web coast pattern moves deeper on the tooth and toward the heel. Consider 0.005” to 0.015” a large change and 0.002” to 0.004” a small change.

Ring and Pinion Gears Choose the Winning Ratio

Ring & pinion set up, Jantz Engineering advanced masters course

Any differential experts care to comment on my ring and pinion pattern

Dana 44 Ring & Pinion Setup, Pattern / Ring Problems? YouTube

Hot Rods Ring and pinion pattern? The H.A.M.B.

How To Create & Read Ring Gear Patterns

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Incorrect pattern adjust backlash, Incorrect pattern adjust pinion

How to Set up Your Rear Gear Correctly RacingJunk News

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

The Procedure Involves Changing The Pinion Position Via Shims In The Carrier And Repositioning The Carrier.

The Swirling Ring Of Cold Air Is Now Spinning In The.

Toyota Gear Installs Arizona By Zuk.

Once The Pinion Gear Is Installed, Position Ring Gear And Carrier Into Housing To Check Backlash.

Related Post: