Ring And Pinion Gear Pattern Chart

Ring And Pinion Gear Pattern Chart - Toyota gear installs arizona by zuk. Web the pattern should be centered on the tooth from face to flank. Carefully apply moderate pressure to the outside ring gear. The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. Web front axles, so use the drive side for reading the pattern. If the gear was manufactured using the face. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web the pattern refers to how the ring gear and pinion gears mesh. Web (1) decreasing backlash moves the ring gear closer to the pinion. Coast pattern (concave side of gear) moves lower and toward the toe. (see figure 2) figure 2: Rotate by grabbing and turning the ring gear, not the pinion. 3) rotate the ring gear in both directions over the painted areas using the pinion yoke to spin it. Pinion resistance against the rotating ring gear helps establish a good pattern. Shallow pinion position, with correct backlash, moves the pinion further from the ring. Web one is manufactured by face hobbing, while the other one is manufactured by face milling. Pinion resistance against the rotating ring gear helps establish a good pattern. The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. Drive pattern (convex side of gear) moves slightly lower and. (see figure 2) figure 2: Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Rotate the ring gear several times by hand and inspect the ring gear teeth. Web closer to the ring gear. Drive patternmoves deeper on the tooth. Web one is manufactured by face hobbing, while the other one is manufactured by face milling. Swapping in 4.10's to my 8.5 10 bolt. (2) increasing backlash moves the ring gear away from the pinion. Web the pattern refers to how the ring gear and pinion gears mesh. Drive pattern moves slightly higher and toward the heel. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. Toyota gear installs arizona by zuk. Move the pinion away from the ring gear centerline. Pinion is too far away. Web this will move the drive side contact point down towards the gear flank (root) and slightly in towards the toe. Pinion is too far away. Rotate by grabbing and turning the ring gear, not the pinion. If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion. I have included two charts here to help you understand and adjust the pattern and backlash. Move the pinion away from the ring. Pinion is too far away. Drive pattern (convex side of gear) moves slightly lower and toward the toe. I have a setup pinion bearing so it is easy for me to pull it apart and change shims. Supply some drag on the ring gear while doing it. Rotate by grabbing and turning the ring gear, not the pinion. (see figure 2) figure 2: Pinion resistance against the rotating ring gear helps establish a good pattern. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. Apply tooth contact compound to the ring gear in two places. Drive patternmoves deeper on the tooth (flank contact) and. Apply tooth contact compound to the ring gear in two places. Web the pattern refers to how the ring gear and pinion gears mesh. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. Pinion is too far away. If the gear was manufactured using the face. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion. You must first determine the type of gear that you have in order to know which. I just needed a baseline for somewhere to go from to get things started. This will help give you a nice clear pattern like this one. There should usually be some clearance between the pattern and the top of the tooth (face), and always between the pattern and the bottom of the tooth (flank). Shallow pinion position, with correct backlash, moves the pinion further from the ring gear. Coast pattern (concave side of gear) moves lower and toward the toe. Swapping in 4.10's to my 8.5 10 bolt. Web one is manufactured by face hobbing, while the other one is manufactured by face milling. Web this will move the drive side contact point down towards the gear flank (root) and slightly in towards the toe. Rotate by grabbing and turning the ring gear, not the pinion. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. Carefully apply moderate pressure to the outside ring gear. Web gm 8.5 gear pattern. The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. 3) rotate the ring gear in both directions over the painted areas using the pinion yoke to spin it. If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion.Ring and Pinion Pattern Help! Ford Bronco Forum

How to Set up Your Rear Gear Correctly RacingJunk News

Ring And Pinion Patterns Explained

How To Create & Read Ring Gear Patterns

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

Ring Gear Contact Pattern

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

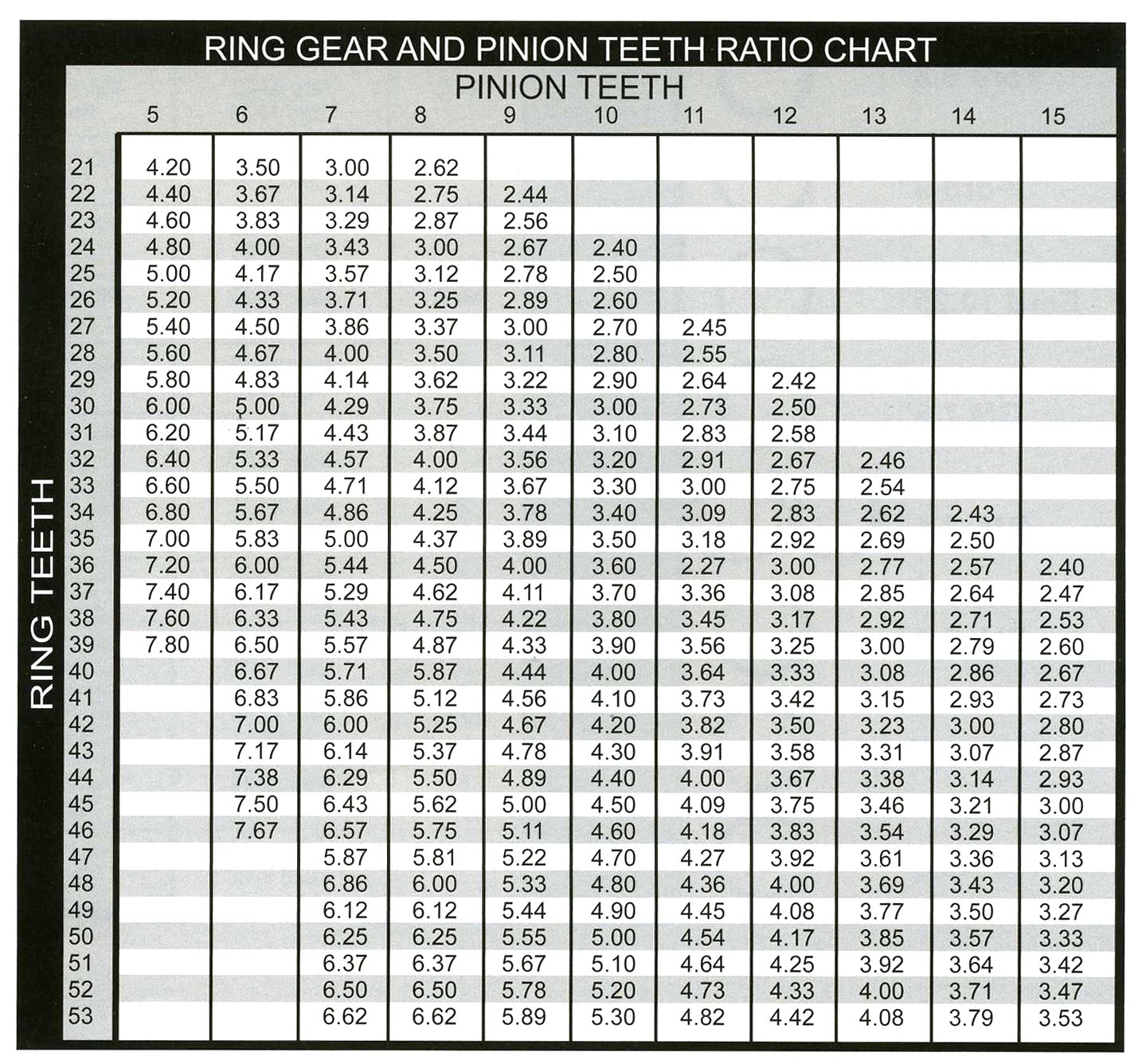

Ring and Pinion Gear Ratio Calculation Chart Quadratec

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Drive Pattern Moves Toward The Top Of The Tooth (Face Contact) And Toward The.

Dialing In The Tolerance Between The Gears Will Ensure A Smooth.

Supply Some Drag On The Ring Gear While Doing It.

The Images Below Illustrate Both Acceptable And Unacceptable Ring And Pinion Gear Patterns.

Related Post: