Push Stick Pattern

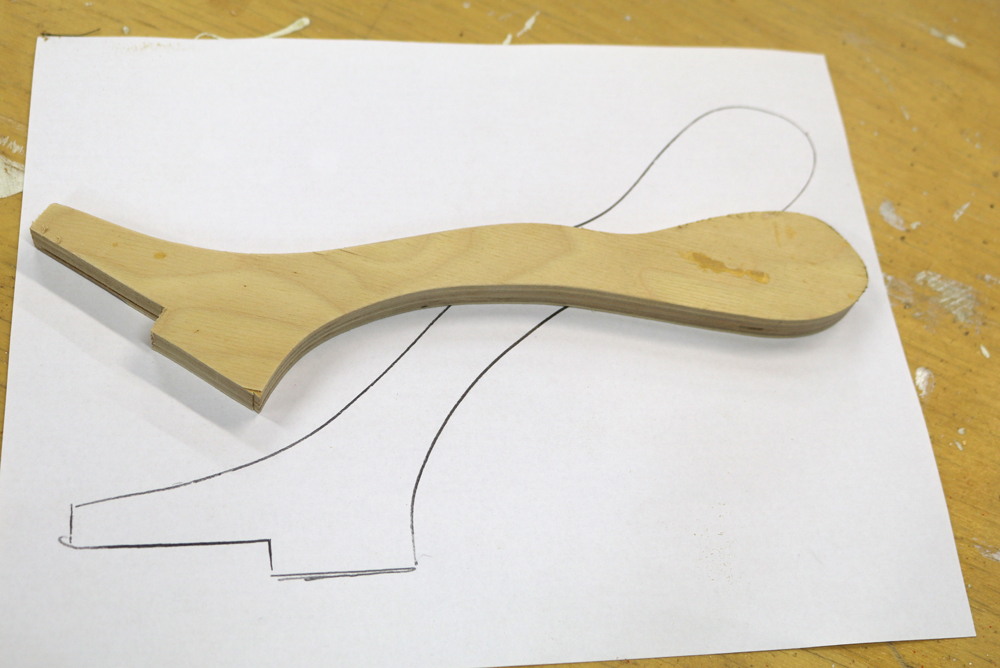

Push Stick Pattern - Once the factory rounded edges are ripped off you have a. The front notch firmly holds the wood so your fingers don’t get too close to the blade. Web using a plywood push stick can help keep your fingers out of the way and give you more confidence. Push stick | cnc | laser | svg | download Making my favourite push stick.download the pattern here:. I traced one of my push sticks and made a pattern for you, it can be downloaded here: Web how to make the best push stick. Web push sticks are used as safety devices during processing on almost all carpentry machines, mainly when working with: Want to make a bunch of awesome push sticks. Neither has a good handle for me to hold onto. Once the factory rounded edges are ripped off you have a. Saw working blade router hand protection. Web a quick and easy to build push stick. To make these thin push sticks i use a piece of 1/4 inch thick hardboard. I traced one of my push sticks and made a pattern for you, it can be downloaded here: Here are my old push sticks that i’ve been using for years and years. It’s nothing more than a block of 2×6. Want to make a bunch of awesome push sticks. X & y dimensions of material or dimensions of entire cnc bed thickness of material 0 on the table no offset. Use good quality straight scrap wood. Web how to make the best push stick. Cut the base in the table saw and the curved parts on the scroll saw. Neither has a good handle for me to hold onto. It’s nothing more than a block of 2×6. Web the best push sticks period || 5 free plans. The back notch holds the wood flat so it doesn’t flip up. If squares on push stick templates are not measuring 1 inch, adjust the scale %. Cut the base in the table saw and the curved parts on the scroll saw. Workshop push sticks and blocks. Workshop push sticks and blocks. Size on your printer settings until squares measure 1 inch. Want to make a bunch of awesome push sticks. Web how to make the best push stick. Push sticks and push blocks. Web the style push stick i’m showing you here is an easy design that you can make without a bandsaw. You can download the plans for free here. Making my favourite push stick.download the pattern here:. Once the factory rounded edges are ripped off you have a. Here are my old push sticks that i’ve been using for years and years. 141k views 3 years ago. Once the factory rounded edges are ripped off you have a. You can download the plans for free here. Push sticks and push blocks. The back notch holds the wood flat so it doesn’t flip up. Today i'll show you how to make a push stick, push blocks, and sanding blocks for your woodshop. Today i'll show you how to make a push stick, push blocks, and sanding blocks for your woodshop. Web pictures from these plans. Web the best push sticks period || 5 free plans. Neither has a good handle for me to hold onto. Web a quick and easy to build push stick. The back notch holds the wood flat so it doesn’t flip up. Web push sticks are used to push stock through your table saw without getting your fingers and hands near the spinning blade. To make these thin push sticks i use a piece of 1/4 inch thick hardboard. Today i'll show you how to make a push stick, push. To make these thin push sticks i use a piece of 1/4 inch thick hardboard. Workshop push sticks and blocks. 175k views 10 years ago. Making my favourite push stick.download the pattern here:. It’s nothing more than a block of 2×6. Here are my old push sticks that i’ve been using for years and years. Making my favourite push stick.download the pattern here:. Here william will show you how to make a jig that will speed up the production process while maintaining consistency. Saw working blade router hand protection. X & y dimensions of material or dimensions of entire cnc bed thickness of material 0 on the table no offset. Workshop push sticks and blocks. Web how to make the best push stick. Web download the free pattern to cut out these push sticks. If squares on push stick templates are not measuring 1 inch, adjust the scale %. Web push sticks are used as safety devices during processing on almost all carpentry machines, mainly when working with: Workshop push sticks and blocks. Here we will discuss how to make push sticks for table saw and other questions related to it. Web using a plywood push stick can help keep your fingers out of the way and give you more confidence. Project from www.craftsmanspace.com push stick plans page 2 of 15 it is desirable that you dispose of several types of push sticks in the workshop (for different machines. You can download the plans for free here. Use adhesive spray to attach the pattern to the wood and cut.

Table saw push stick DIY » Famous Artisan

The Best Push Stick (w/pdf template) YouTube

Woodworking Template Table Saw Push Sticks Kurt's Blog

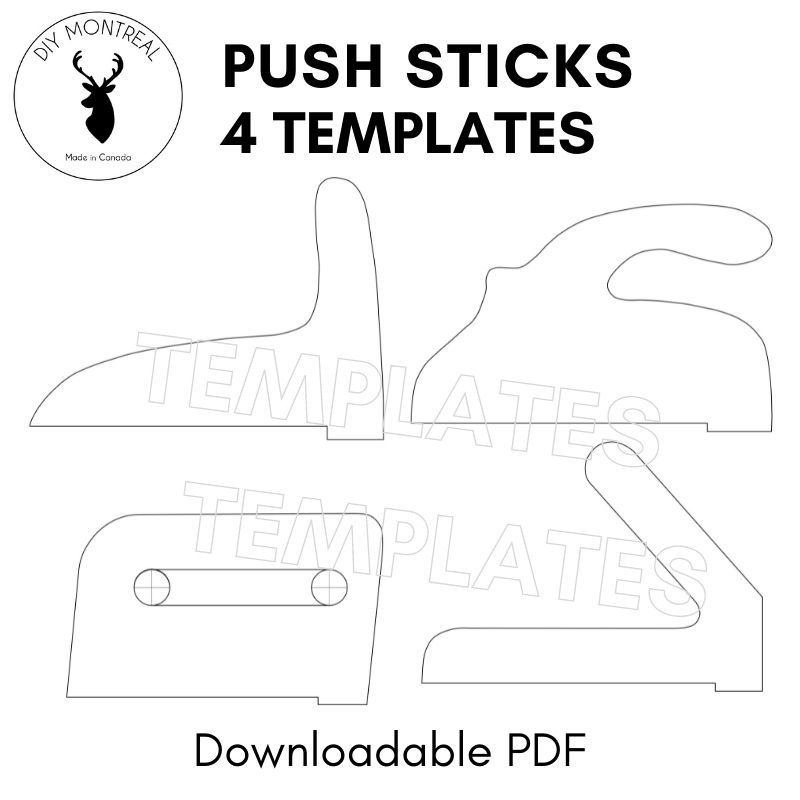

Push Sticks Printable Templates 4 Designs DIY Montreal

Pattern Table Saw Push Stick Printable Template Printable Templates

PushStick for Table Saw Free Design Plans Longview Woodworking

Collection Of Wood Push Sticks For Table Saw Handmade From 1/2" or 3/

How To Make A Push Stick YouTube

How to make quick and easy push sticks. YouTube

Saw Handle Push Stick Design Files for CNC Fusion 360 Etsy

Size On Your Printer Settings Until Squares Measure 1 Inch.

Web The Style Push Stick I’m Showing You Here Is An Easy Design That You Can Make Without A Bandsaw.

Web A Quick And Easy To Build Push Stick.

Cut The Base In The Table Saw And The Curved Parts On The Scroll Saw.

Related Post: