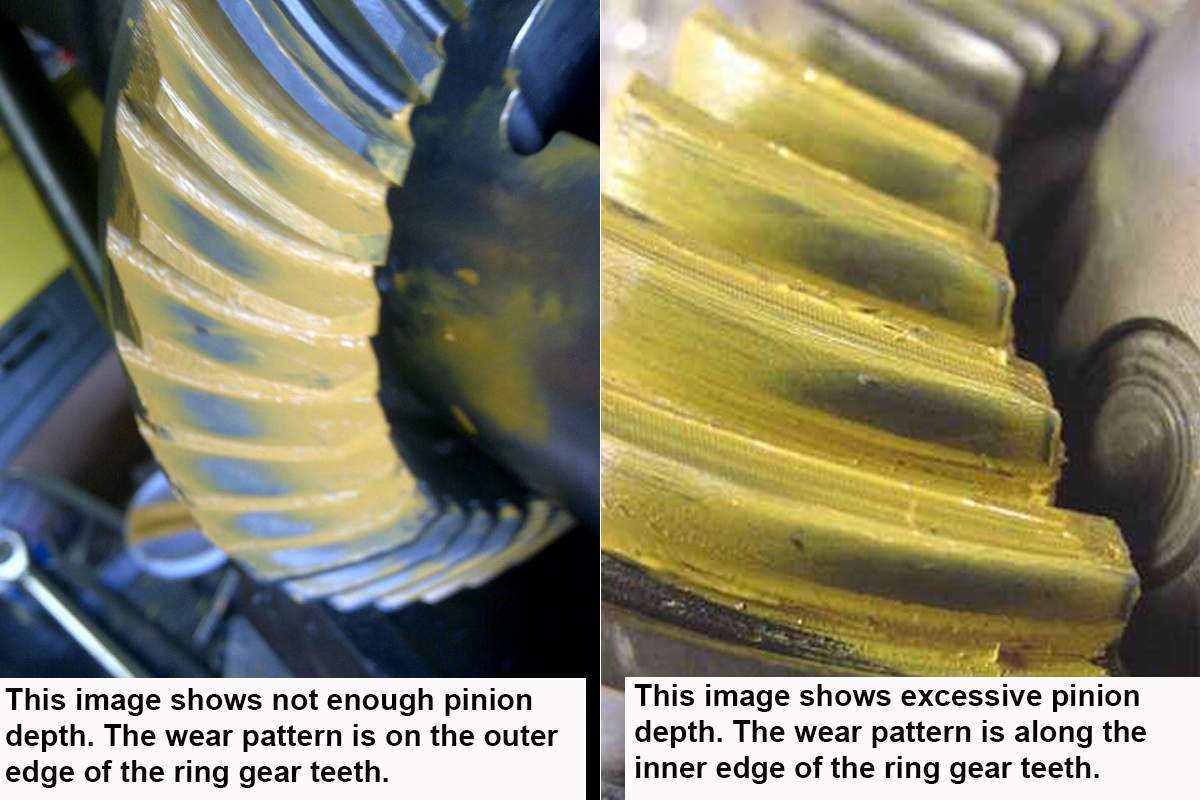

Pinion Too Deep Pattern

Pinion Too Deep Pattern - But based on the pattern shown on the coast side of your ring gear, i also agree. This is shown by the wear pattern on the inside of the teeth. The gauge will get you close, but final adjustments shoud always be made by what the. During initial setup, try using the. Web yes, those etched numbers on the top of the pinion acutually have meaning and are quite important to getting a good pattern. Web in this image, the pinion depth is too deep (too far into the housing) and needs more shims. Web it is more important to see the contact pattern for the drive side of the ring gear. Web one of the most common methods for verifying the pinion depth is through gear pattern inspection. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web (www.differentials.com), pinion depth shims are placed either under the rear pinion race or on the pinion shaft under the rear pinion bearing. If your pattern does not look like the ones. Web it is more important to see the contact pattern for the drive side of the ring gear. During initial setup, try using the. A correct pattern should look like this: Web using gear marking compound and a clean brush, check the pattern on your ring & pinion setup. But based on the pattern shown on the coast side of your ring gear, i also agree. Web a close look shows the pattern has flipped, an indication that i was now too deep in mesh. Pinion depth is how far the head of the pinion gear is from the centerline of the differential carrier and axles when everything. Web. Web the pinion is too close to the carrier and imo you should try removing the shims as your original thought seems to have played out. This is shown by the wear pattern on the inside of the teeth. Web one of the most common methods for verifying the pinion depth is through gear pattern inspection. Web when setting up. If your pattern does not look like the ones. Web one of the most common methods for verifying the pinion depth is through gear pattern inspection. Web when setting up a ring & pinion, there are four critical settings that need to be correct in order to get proper setup and good gear life. Web achieving the correct pinion depth. Web one of the most common methods for verifying the pinion depth is through gear pattern inspection. This is shown by the wear pattern on the inside of the teeth. If you don't have these numbers on. Web a pinion that's too deep leaves an impression closer to the id of the ring gear, not the outside. A contact pattern. Web achieving the correct pinion depth ensures proper gear mesh, translating to efficient power transfer, minimal wear and tear, and reduced noise and vibration. This video was created to give people a basic understanding of how. If your pattern does not look like the ones. Web it is more important to see the contact pattern for the drive side of. The gauge will get you close, but final adjustments shoud always be made by what the. This involves applying a special marking compound to the. Web a contact pattern centered from face to flank indicates the correct pinion depth. During initial setup, try using the. But based on the pattern shown on the coast side of your ring gear, i. Increasing pinion depth moves the. I was now at net.030 for the pinion shim, getting closer to my. Web using gear marking compound and a clean brush, check the pattern on your ring & pinion setup. Web when setting up a ring & pinion, there are four critical settings that need to be correct in order to get proper setup. Web in this image, the pinion depth is too deep (too far into the housing) and needs more shims. Web one of the most common methods for verifying the pinion depth is through gear pattern inspection. This video was created to give people a basic understanding of how. The gauge will get you close, but final adjustments shoud always be. But based on the pattern shown on the coast side of your ring gear, i also agree. Web the pinion is too close to the carrier and imo you should try removing the shims as your original thought seems to have played out. Web what are pinion depth and backlash? A correct pattern should look like this: If you don't. Web a pinion that's too deep leaves an impression closer to the id of the ring gear, not the outside. Web in this image, the pinion depth is too deep (too far into the housing) and needs more shims. I was now at net.030 for the pinion shim, getting closer to my. Pinion depth is how far the head of the pinion gear is from the centerline of the differential carrier and axles when everything. A contact pattern closer to the gear face means the pinion is too far away from the. But based on the pattern shown on the coast side of your ring gear, i also agree. Web achieving the correct pinion depth ensures proper gear mesh, translating to efficient power transfer, minimal wear and tear, and reduced noise and vibration. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web a close look shows the pattern has flipped, an indication that i was now too deep in mesh. This video was created to give people a basic understanding of how. Web (www.differentials.com), pinion depth shims are placed either under the rear pinion race or on the pinion shaft under the rear pinion bearing. Web the only true way to set the pinion depth is by reading the contact pattern. Web using gear marking compound and a clean brush, check the pattern on your ring & pinion setup. Imo the pinion is too far away. Web what are pinion depth and backlash? Web yes, those etched numbers on the top of the pinion acutually have meaning and are quite important to getting a good pattern.

Setting Pinion Depth and Backlash RacingJunk News

How to Set up Your Rear Gear Correctly RacingJunk News

Setting Pinion Depth and Backlash RacingJunk News

gear pattern check, pinion too deep no more shims to remove Pirate 4x4

Ring and Pinion Contact Pattern With Change of Pinion Depth. YouTube

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Ring & Pinion Patterns explained, back lash vs pinion depth YouTube

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Dana 44 Ring & Pinion Setup, Pattern / Ring Problems? YouTube

Any differential experts care to comment on my ring and pinion pattern

Web A Contact Pattern Centered From Face To Flank Indicates The Correct Pinion Depth.

If Your Pattern Does Not Look Like The Ones.

The Gauge Will Get You Close, But Final Adjustments Shoud Always Be Made By What The.

Web One Of The Most Common Methods For Verifying The Pinion Depth Is Through Gear Pattern Inspection.

Related Post: