Pinion Gear Wear Patterns

Pinion Gear Wear Patterns - The bearing contact in a face gear drive is localized (see section 1.3) to avoid the separation of tooth surfaces and edge contact. In this video we give a. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly. Yukon provides highest quality drivetrain parts including differentials, axles,. Web this is a demonstration of the proper setup of a ring and pinion gear set in the rear. More than ring & pinion gearsets and differential bearing kits,. Web of a face gear drive is an involute spur pinion. Find answers to the most asked questions about your purchase, order or shipping. Motive gear offers the best value for drivetrain components. The bearing contact in a face gear drive is localized (see section 1.3) to avoid the separation of tooth surfaces and edge contact. Web 51k views 8 years ago. Web the final pinion position will be verified by. In this work, basic information about the design and analysis of face gear drives is presented. Find answers to the most asked questions about your purchase, order or shipping. In this video we give a. Ensuring peak performance and longevity. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly. Web this leads to drive system weight reduction and improvements in performance. Web the pinion gear teeth have worn down to a very sharp edge. The toe of the gear is the portion of the tooth surface. While we can’t physically see how the gears actually relate. Click here for a larger image. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web motive gear is your source for maximum power. Web the pinion gear teeth have worn down to a very sharp edge. Ensuring peak performance and longevity. In this work, basic information about the design and analysis of face gear drives is presented. Web motive gear is your source for maximum power. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble. Web this leads to drive system weight reduction and improvements in performance. Web richmond’s excel branded gearing, axles and differential components offer richmond quality at affordable prices for oem driveline replacement parts. See how to set up. Web of a face gear drive is an involute spur pinion. Web pattern should range from just clear of the toe end to about 3/8” off the toe end. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble. Web the pinion gear teeth have worn down to a very sharp edge. See how to set. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble. 32k views 9 months ago. Web this is a demonstration of the proper setup of a ring and pinion gear set in the rear. Web of a face gear drive is an. Web richmond’s excel branded gearing, axles and differential components offer richmond quality at affordable prices for oem driveline replacement parts. Web the pinion gear teeth have worn down to a very sharp edge. Web pattern should range from just clear of the toe end to about 3/8” off the toe end. In this video we give a. The bearing contact. See how to set up a ring and pinion gear set. Ideal contact pattern is spread evenly over tooth's profile with concentration nearer toe than heel. While we can’t physically see how the gears actually relate. Web the pinion gear teeth have worn down to a very sharp edge. More than ring & pinion gearsets and differential bearing kits,. While we can’t physically see how the gears actually relate. Web of a face gear drive is an involute spur pinion. Ensuring peak performance and longevity. Web this leads to drive system weight reduction and improvements in performance. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web pattern should range from just clear of the toe end to about 3/8” off the toe end. Motive gear offers the best value for drivetrain components. While we can’t physically see how the gears actually relate. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Web motive gear is your source for maximum power. One of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. In this work, basic information about the design and analysis of face gear drives is presented. The bearing contact in a face gear drive is localized (see section 1.3) to avoid the separation of tooth surfaces and edge contact. See how to set up a ring and pinion gear set. Find answers to the most asked questions about your purchase, order or shipping. The pattern should be evenly centered between tooth top land and root. Web in general, pattern movements can be summarized this way: Web the final pinion position will be verified by using the gear contact pattern method described as follows: Web 51k views 8 years ago.RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

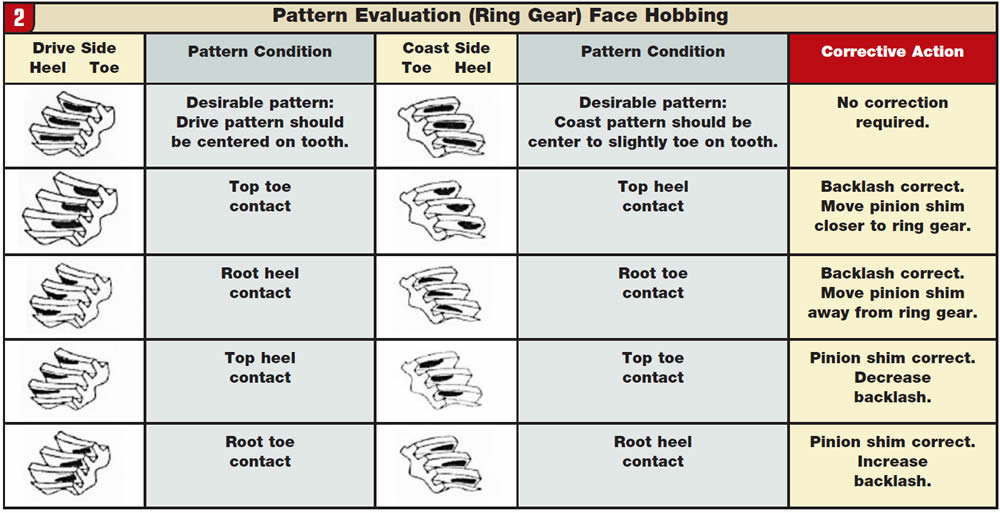

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Ring and Pinion Pattern Help! Ford Bronco Forum

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Déjà Vu All Over Again Understanding RingandPinion Setup

Once backlash is within spec you can set the pinion depth by reading

Pinion/ring gear wear pattern ?

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Pinion/ring gear wear pattern ?

Pinion/ring gear wear pattern ?

Ideal Contact Pattern Is Spread Evenly Over Tooth's Profile With Concentration Nearer Toe Than Heel.

The Toe Of The Gear Is The Portion Of The Tooth Surface.

Web Richmond’s Excel Branded Gearing, Axles And Differential Components Offer Richmond Quality At Affordable Prices For Oem Driveline Replacement Parts.

Web Every Gear Has A Characteristic Pattern.

Related Post: