Pier Foundry And Pattern Shop

Pier Foundry And Pattern Shop - Web pier foundry & pattern shop weigh counts all of the castings it ships to its customers to ensure an accurate quantity. Web pier foundry offers solutions to arrange and manage all of your secondary operations. Reduce internal & external scrap. Conversion will reduce manufacturing time, improve cosmetic appearance & can save 30. Web all of the tooling used at pier foundry is created from 3d cad models and cnc cut to ensure the utmost accuracy. Web pier foundry and pattern shop is passionately committed to providing you with the highest level of service, support and value which you expect from a grey iron and ductile. A pre & post production inspection takes place on all. Web pier foundry & pattern shop can take your existing weldment and convert it into a casting. We offer inventory management including kanban & jit. Industrial foundry patterns (cope & drag / split p/l's) and core boxes. Web pier foundry & pattern shop weigh counts all of the castings it ships to its customers to ensure an accurate quantity. Reduce internal & external scrap. Web pier foundry offers solutions to arrange and manage all of your secondary operations. During cleaning, castings undergo a tumble blasting process to remove all excess sand from the casting. We utilize both. Conversion will reduce manufacturing time, improve cosmetic appearance & can save 30. We offer a variety of value added services including but not limited to: Web all of the tooling used at pier foundry is created from 3d cad models and cnc cut to ensure the utmost accuracy. Web pier foundry offers solutions to arrange and manage all of your. We offer a variety of value added services including but not limited to: After blasting, iron castings are ground to. Web pier foundry & pattern shop can take your existing weldment and convert it into a casting. Conversion will reduce manufacturing time, improve cosmetic appearance & can save 30. Web a core is used to produce a cavity or an. We utilize both cold and warm box. Reduce internal & external scrap. Web recycling and beneficial use of foundry byproducts; Conversion will reduce manufacturing time, improve cosmetic appearance & can save 30. Web pier foundry & pattern shop weigh counts all of the castings it ships to its customers to ensure an accurate quantity. Web pier foundry & pattern shop weigh counts all of the castings it ships to its customers to ensure an accurate quantity. Web today pier foundry is one of the most efficient, and modern jobbing shops in the upper midwest. We utilize both cold and warm box. Web pier foundry and pattern shop is passionately committed to providing you with. Web pier foundry and pattern shop is passionately committed to providing you with the highest level of service, support and value which you expect from a grey iron and ductile. Web pier foundry & pattern shop can take your existing weldment and convert it into a casting. Reduce internal & external scrap. With the addition of electric melting, automatic molding. Web a core is used to produce a cavity or an interior detail on a casting. Web pier foundry and pattern shop is passionately committed to providing you with the highest level of service, support and value which you expect from a grey iron and ductile. We utilize both cold and warm box. With the addition of electric melting, automatic. Web all of the tooling used at pier foundry is created from 3d cad models and cnc cut to ensure the utmost accuracy. A pre & post production inspection takes place on all. We offer a variety of value added services including but not limited to: Web a core is used to produce a cavity or an interior detail on. Web pier foundry & pattern shop can take your existing weldment and convert it into a casting. After blasting, iron castings are ground to. We offer a variety of value added services including but not limited to: Industrial foundry patterns (cope & drag / split p/l's) and core boxes. Web pier foundry offers solutions to arrange and manage all of. With the addition of electric melting, automatic molding and material handling,. Reduce internal & external scrap. We utilize both cold and warm box. Pier foundry has the capability to produce cores from ounces to 70 lbs. During cleaning, castings undergo a tumble blasting process to remove all excess sand from the casting. Pier foundry has the capability to produce cores from ounces to 70 lbs. Reduce internal & external scrap. Web pier foundry offers solutions to arrange and manage all of your secondary operations. After blasting, iron castings are ground to. Conversion will reduce manufacturing time, improve cosmetic appearance & can save 30. With the addition of electric melting, automatic molding and material handling,. Industrial foundry patterns (cope & drag / split p/l's) and core boxes. Web today pier foundry is one of the most efficient, and modern jobbing shops in the upper midwest. Web pier foundry & pattern shop can take your existing weldment and convert it into a casting. Web all of the tooling used at pier foundry is created from 3d cad models and cnc cut to ensure the utmost accuracy. Web recycling and beneficial use of foundry byproducts; Web pier foundry & pattern shop weigh counts all of the castings it ships to its customers to ensure an accurate quantity. We utilize both cold and warm box. We offer inventory management including kanban & jit. We offer a variety of value added services including but not limited to:

Pouring Pier Foundry

Engineering Pier Foundry

Pier Foundry Invests in Sinto FBOIIIS Mold Machine & Handling System

Facility Pier Foundry

Pattern Shop South Lincs Foundry

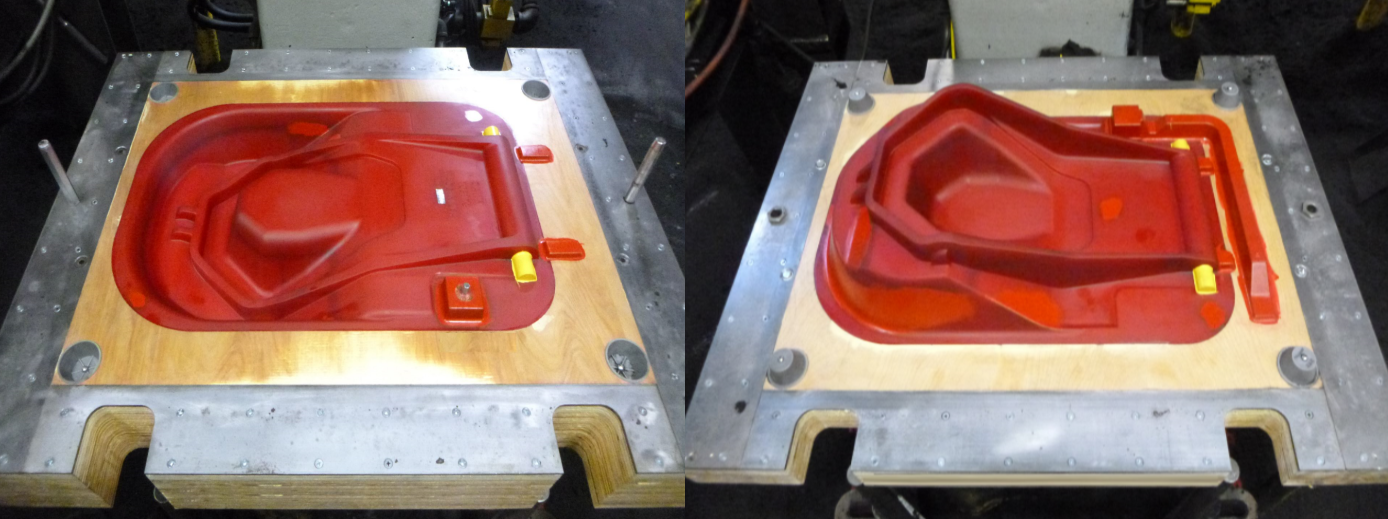

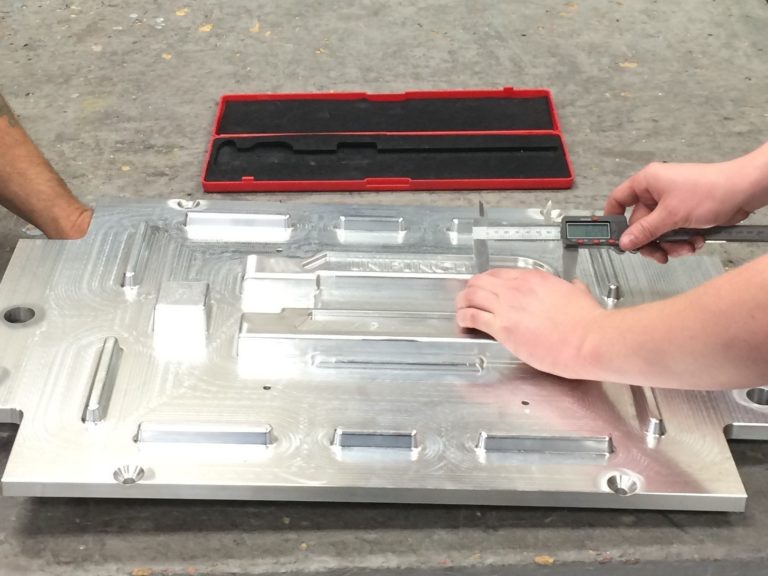

Pattern Tooling Pier Foundry

Facility Pier Foundry

Molding Pier Foundry

Pouring Pier Foundry

Sand Casting Pattern Design Foundry Pattern Shop Badger Alloys

A Pre & Post Production Inspection Takes Place On All.

During Cleaning, Castings Undergo A Tumble Blasting Process To Remove All Excess Sand From The Casting.

Web Pier Foundry And Pattern Shop Is Passionately Committed To Providing You With The Highest Level Of Service, Support And Value Which You Expect From A Grey Iron And Ductile.

Web A Core Is Used To Produce A Cavity Or An Interior Detail On A Casting.

Related Post: