Pattern Welded

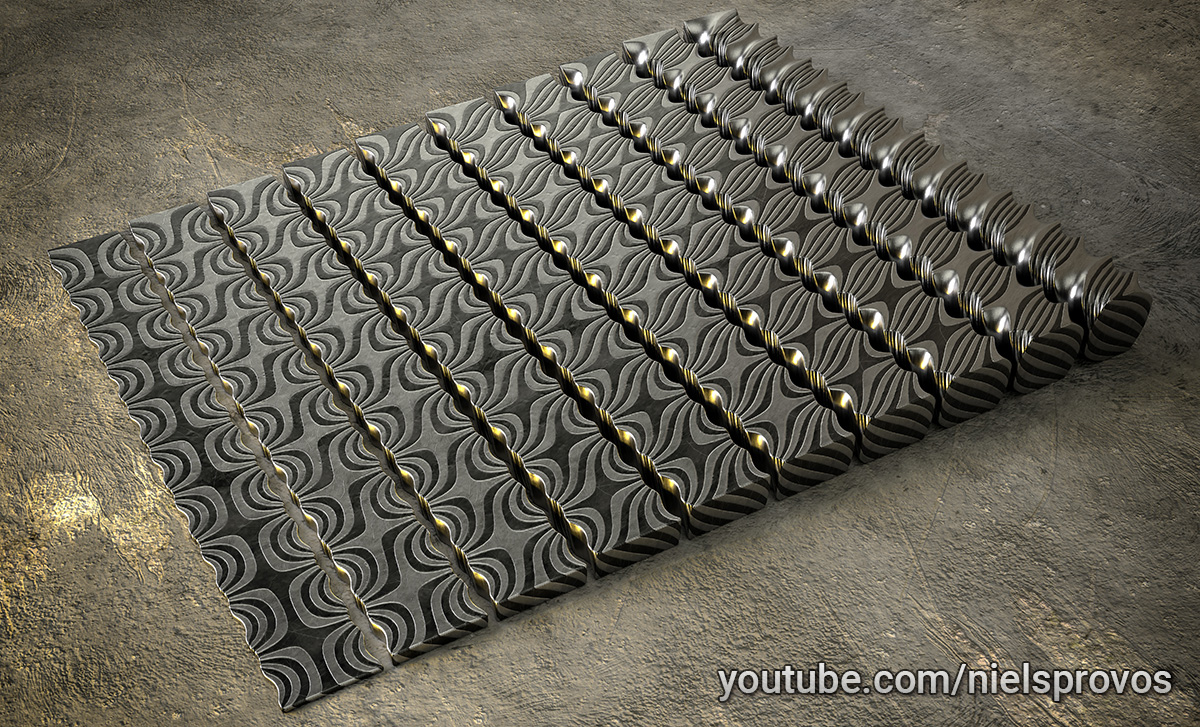

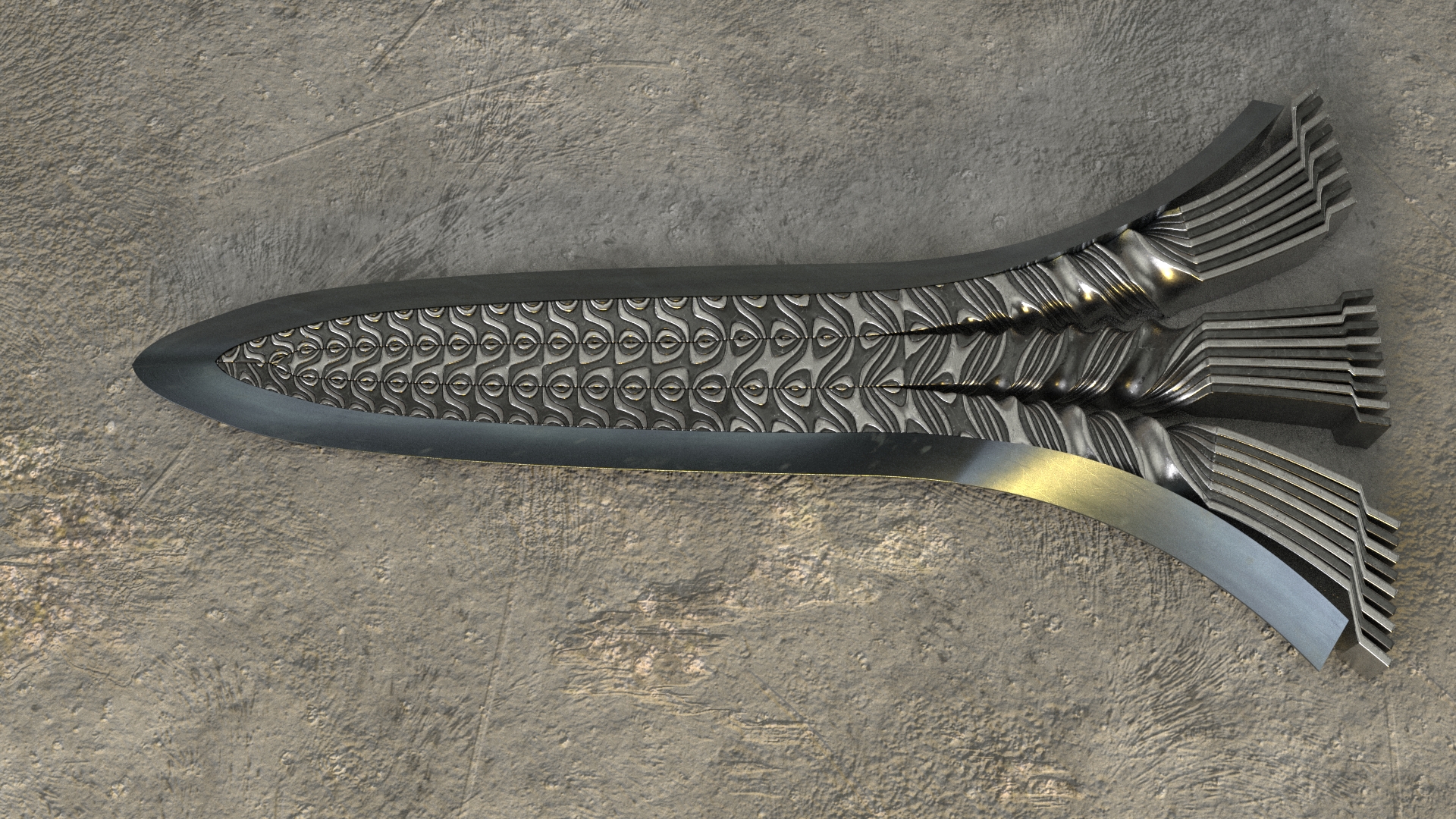

Pattern Welded - You will also need to clean the washers to remove the fire scale. I’m often asked where the patterns in my steel come from. Web forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Web pattern welded steel covering the soft iron core had a similar purpose to the san mai knives of the japanese. The plates are heated to increase deformability of the material. Web making raindrop damascus by forge welding 15n20 and 1070 high carbon steel.huge thanks to @mymechanicsinsights for making me new flat dies and enabling this. Pattern welding is more common than believed in history. The technique is an extensive process that creates a strong, hard, and flexible steel. Unlike wootz steel, whose pattern arises from the presence of one or more impurities, pattern welded steel is the deliberate combination of billets made from different metals (iron alloys) during the making of a blade. It is not however, any form of magic. The esthetic result is similar: However, rust and other oxidation forms make it challenging to notice the. The iron or steel used must be contrasting so that they are optically different and should be visible at the surface of the sword. Web the process of pattern welding. Web pattern welding offers a middle way out of the dichotomy between rigorous. Web the seax can vary greatly in form , from a small 5” long scramaseax used for every day tasks, to the 24”+. Web forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Pattern welding is more common than believed in history. Web pattern welding, developed for laminated or laminated steel,. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. Web pattern welding is the process of mixing different steels by forging. Heat up all the spring steel washers in the forge, and straighten them. These are the most basic damascus patterns and the same patterning techniques,. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipu. Web pattern welded steel covering the soft iron core had a similar. Pattern welded steel has also been around for many centuries, from approximately the 2nd century ad [5], produced in swords in europe in different locations. Usually by folks who aren’t familliar with pattern welded steel. It is not however, any form of magic. Web pattern welding is the process of mixing different steels by forging. Web the seax can vary. The soft iron core would absorb impact and shock without bending or chipping the cutting edge. Web pattern welded steel covering the soft iron core had a similar purpose to the san mai knives of the japanese. Before moving on to more advanced patterns and techniques, the damascus steel maker should become adept at the forge. These are the most. Moran displayed his knives at the knifemakers’ guild show. Waves and circular patterns of light and. The technique is an extensive process that creates a strong, hard, and flexible steel. Before moving on to more advanced patterns and techniques, the damascus steel maker should become adept at the forge. The simple “friendly to the folks” version describes how the pattern. The technique is an extensive process that creates a strong, hard, and flexible steel. When somebody who is familiar with pattern welding, whether it be in. Web pattern welding is the process of mixing different steels by forging. Pattern welded steel has also been around for many centuries, from approximately the 2nd century ad [5], produced in swords in europe. However, rust and other oxidation forms make it challenging to notice the. Web the process of pattern welding. The soft iron core would absorb impact and shock without bending or chipping the cutting edge. Virtually all existing swords from these times are in excavated condition and in many cases weak acidity in the earth or water. Forge welding differs from. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. Web pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipu. Web pattern welding was an outgrowth of laminated or piled steel, a. The nails are naturally scarfed. It is not however, any form of magic. Waves and circular patterns of light and. Web pattern welding is the process of mixing different steels by forging. The soft iron core would absorb impact and shock without bending or chipping the cutting edge. Web pattern welding is a process used to forge and create a composite steel material with distinctive patterns. Usually by folks who aren’t familliar with pattern welded steel. Web pattern welding was an outgrowth of laminated or piled steel, a similar technique used to combine steels of different carbon contents, providing a desired mix of hardness and toughness. Pattern welded steel has also been around for many centuries, from approximately the 2nd century ad [5], produced in swords in europe in different locations. Many but not all seaxs are pattern welded and the complexity of the patterning vary s greatly with region, time and presumably with the wealth of the original owner. The technique is an extensive process that creates a strong, hard, and flexible steel. That is, welds made below the temperature of fusion. Pattern welding is more common than believed in history. Web pattern welding, developed for laminated or laminated steel, is a comparable method for the fusion of steels with different levels of carbon to obtain the desired combination of toughness and hardness. I’m often asked where the patterns in my steel come from. Web the process of pattern welding.

Pattern Welding Explained

Pattern Welding Explained

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

welding art projects for beginners Weldingart Welding art, Welding

How Pattern Welded Steel is Made Explained by Blacksmiths (Part 2 of

Pattern welded Damascus steel knives KnifesDaggersSwords Pinter…

a pattern welded Viking sword part 1. YouTube

Weaving in welding A comprehensive guide to weave patterns

Everything about Pattern Welding Steel

Help me understand pattern welding. Beginners Place Bladesmith's

Web The Seax Can Vary Greatly In Form , From A Small 5” Long Scramaseax Used For Every Day Tasks, To The 24”+.

When Somebody Who Is Familiar With Pattern Welding, Whether It Be In.

The Esthetic Result Is Similar:

Before Moving On To More Advanced Patterns And Techniques, The Damascus Steel Maker Should Become Adept At The Forge.

Related Post: