Pattern Weld

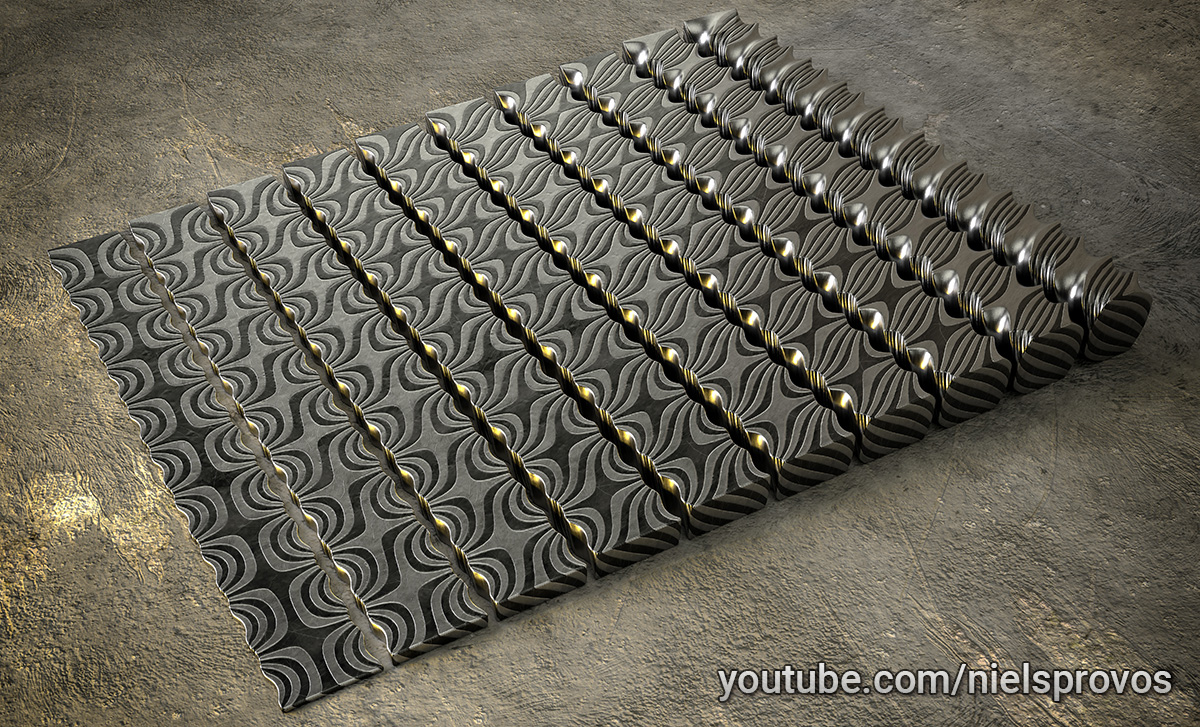

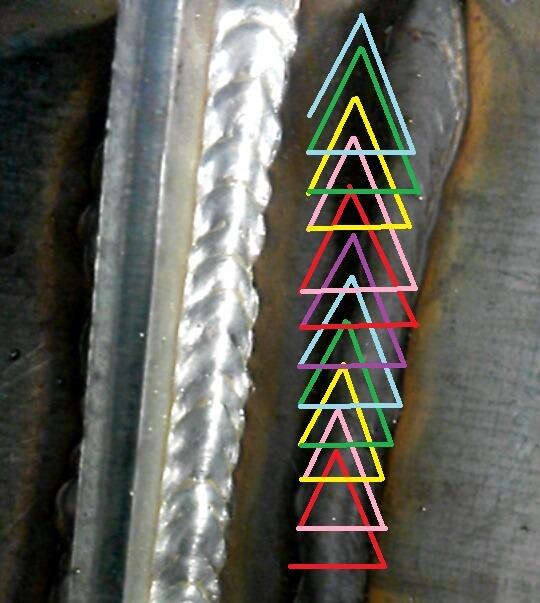

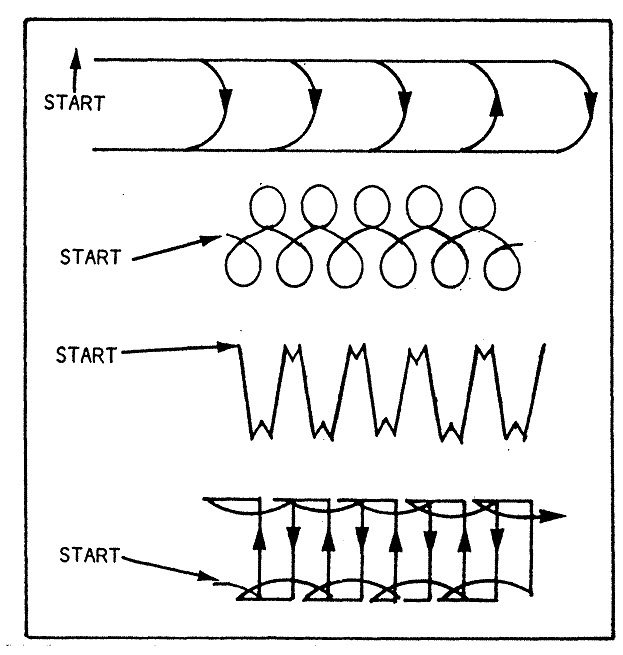

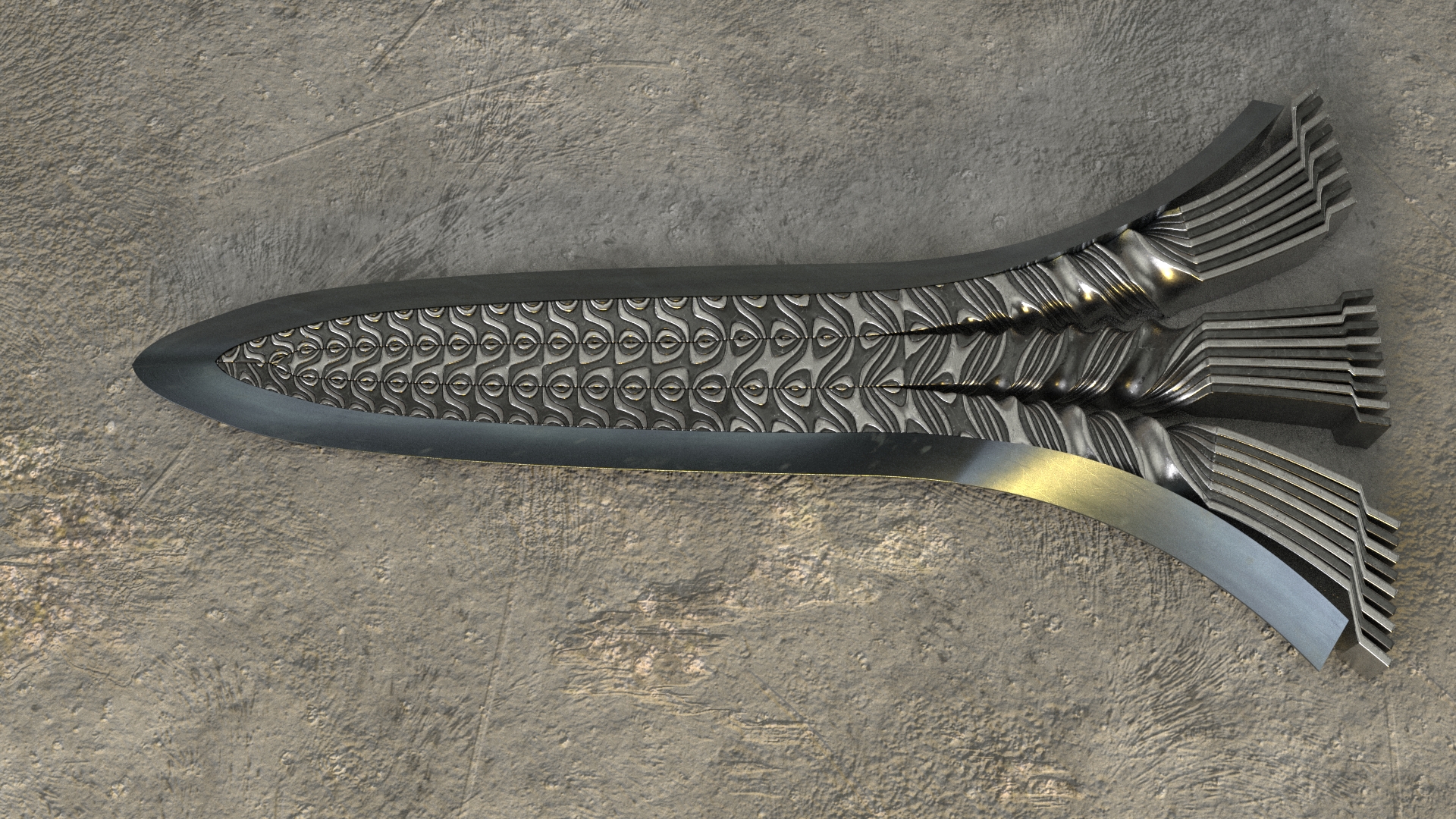

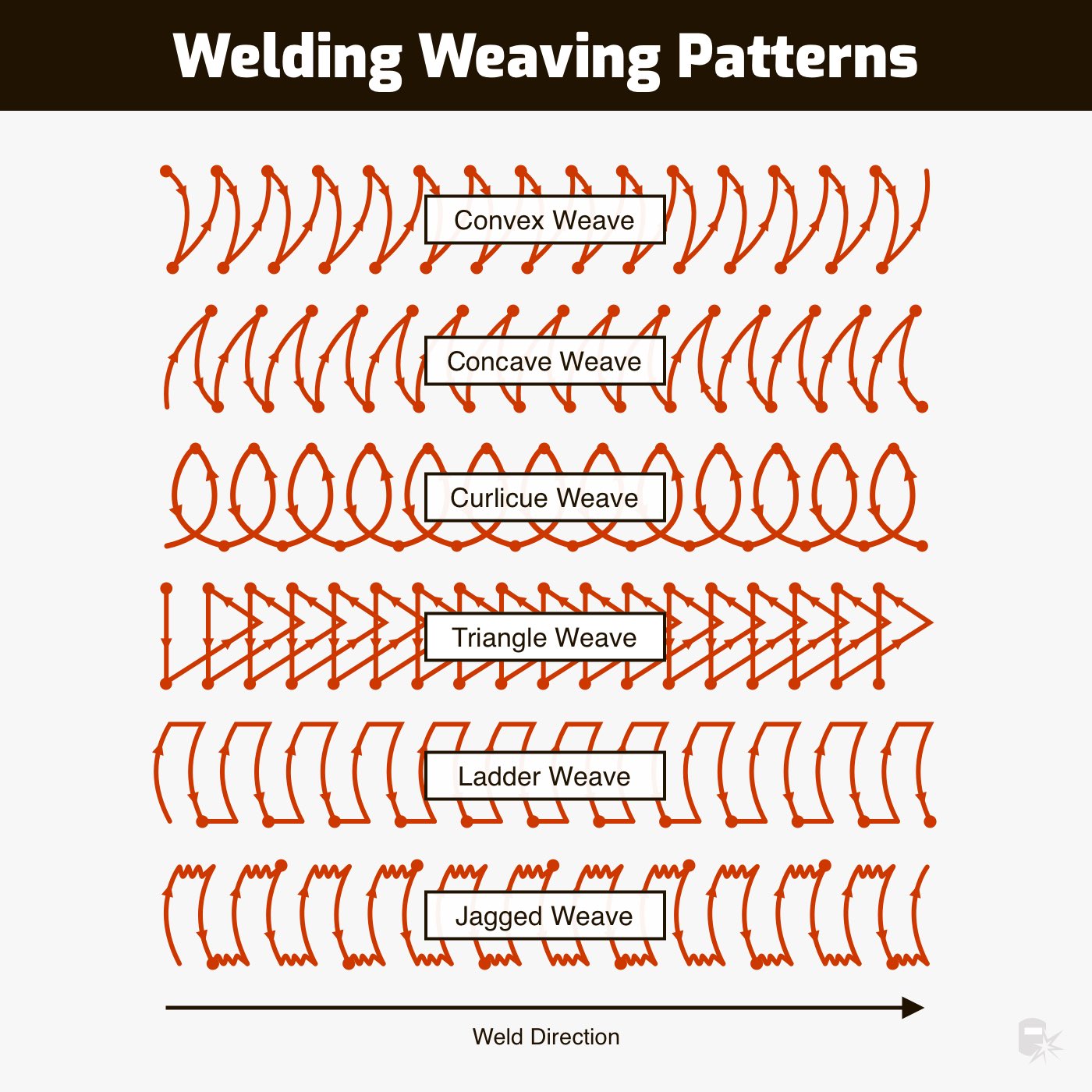

Pattern Weld - Web mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. Dealing with medium and high carbon steels. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. Forge welding differs from more more modern welding techniques such as smaw (shielded metal arc welding, commonly called “stick” welding), fcaw (flux core arc welding, commonly. Web generally speaking, there are two main welding bead techniques and patterns: Each pattern describes a specific movement or shape that the welder’s hand makes during the welding process. Web posted on september 2, 2010 by dekerseptember 2, 2010. Here is something easy that will get you started and boost your confidence. Web what patterns do is help spread out the weld the way you would spread peanut butter on bread. Pattern welding is the process of mixing different steels by forging. Web mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. Web pattern welding, also known as damascus steel or damascene technique, is a traditional method of forging metals to create intricate patterns and designs. There are several benefits of. Welders can craft various designs, such as crescent and zigzag weaving patterns. Not only among the general populous, but even among bladesmiths. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. There are several benefits of employing weaving patterns in. Pattern welding is the process of. Here is something easy that will get you started and boost your confidence. Web pattern welding, also known as damascus steel or damascene technique, is a traditional method of forging metals to create intricate patterns and designs. 60k views 2 years ago. Web the j welding technique is good for some lap joints and butt welds. Web what patterns do. Welders can craft various designs, such as crescent and zigzag weaving patterns. Web have you cried blood when attempting your first pattern welded blade? Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated. Forge welding differs from more more modern welding techniques such as smaw. Pattern welding is an amazing and amazingly old process where two different steels are forge welded together and beaten, twisted, folded and generally manipulated. Web mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. Pattern welding is the process of mixing different steels by forging. However, once you decide to. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. It makes thing smooth and uniform. All patterns have pros and cons, difficulty levels, and the best situations to use them. This is a good technique to use when you are in the vertical welding position or the overhead. It involves the joining and layering of different types of metals to produce a visually appealing and structurally strong composite material. However, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld. This is a good technique to use when you are in the vertical welding. It makes thing smooth and uniform. Web what patterns do is help spread out the weld the way you would spread peanut butter on bread. The number of layers increases nearly exponentially with the number of welds. All patterns have pros and cons, difficulty levels, and the best situations to use them. A circular motion can be a good technique. The simple “friendly to the folks” version describes how the pattern is actually in the steel itself, and not just on the surface. Forge welding differs from more more modern welding techniques such as smaw (shielded metal arc welding, commonly called “stick” welding), fcaw (flux core arc welding, commonly. It involves the joining and layering of different types of metals. The number of layers increases nearly exponentially with the number of welds. This is a good technique to use when you are in the vertical welding position or the overhead welding position. All patterns have pros and cons, difficulty levels, and the best situations to use them. Dealing with medium and high carbon steels. Here is something easy that will. Usually by folks who aren’t familliar with pattern welded steel. Web posted on september 2, 2010 by dekerseptember 2, 2010. However, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld. There are several benefits of employing weaving patterns in. Web the j welding technique is good for some lap joints and butt welds. Forge welding is second only to material preparation in importance in the creation of quality pattern welded steel. Web mig welding patterns are the varied ways in which the welding gun is manipulated to lay down the weld. Pattern welding is the process of mixing different steels by forging. Web pattern welding is the process of welding together plates of high, low and sometimes intermediate carbon content steels, drawing them out, cutting and rewelding repeatedly until the desired fineness of material distribution is achieved. Web what is pattern welding? I was reminded last night that there are still many misconceptions on damascus, pattern welding, and wootz steel. The number of layers increases nearly exponentially with the number of welds. This is a recyclable instructible as well as. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. So, i think i’m going to try and begin work on a section.continue reading →. Web what patterns do is help spread out the weld the way you would spread peanut butter on bread.

6 Essential MIG Welding Patterns To Master

Pattern Welding Explained

The Art of Pattern Welding and Damascus Steel HDMD Knives Blog

Welding Basics Weld Beads Kyle's Garage

Welding the Way — There are several types of bead weave patterns...

Welding Techniques

welding art projects for beginners Weldingart Welding art, Welding

Pattern Welding Explained

Weaving in welding A comprehensive guide to weave patterns

Welding Beads What Are They? & Different Types

This Instructible Assumes A Working Knowledge Of Pattern Welding.

Not Only Among The General Populous, But Even Among Bladesmiths.

60K Views 2 Years Ago.

It Makes Thing Smooth And Uniform.

Related Post: