Pattern Molding

Pattern Molding - The first step in shell molding is creating a pattern part. Once the mold is complete, the match plate pattern is removed and the molten metal is poured into the mold cavity. Web patterns are a fundamental part of the casting process, ensuring that the end products are produced with the desired dimensions and quality. Create all the pattern parts. This is achieved by first machining a metal pattern tool, usually from iron. Web wax pattern molding is a specialized technique used in the production of intricate and complex metal components. Some of the basics you need to know if you are going to make a pattern to have cast in metal at a foundry along with examples of. Web patternmaking, in materials processing, the first step in casting and molding processes, the making of an accurate model of the part, somewhat oversize to allow for shrinkage of. In terms of structure, molds have concave shapes (negative mold) or convex shapes (positive mold) designed according to the final design the manufacturer intends to create. • draft—is the angle applied to. In terms of structure, molds have concave shapes (negative mold) or convex shapes (positive mold) designed according to the final design the manufacturer intends to create. There are different types of patterns in casting. This is achieved by first machining a metal pattern tool, usually from iron. The first step in shell molding is creating a pattern part. This is. Create all the pattern parts. Some of them are briefly. Web the match plate pattern is placed in a mold box and the molding sand is packed around it to create the mold cavity. It involves creating a precise wax replica, also known as a. Web in casting, a pattern is a replica of the object to be cast, used. Web accurate pattern designs and builds plugs and molds for fiberglass composite laminating customers in the aerospace, energy, military, transportation and related industries. It involves creating a precise wax replica, also known as a. Web the match plate pattern is placed in a mold box and the molding sand is packed around it to create the mold cavity. So the. When deciding on types of trim. Web accurate pattern designs and builds plugs and molds for fiberglass composite laminating customers in the aerospace, energy, military, transportation and related industries. Over the past 5 decades, we have cultivated. An explanation of each of these three “tricks” is given below: Some of them are briefly. Web patterns are a fundamental part of the casting process, ensuring that the end products are produced with the desired dimensions and quality. Web pattern, mold and core design involves orientation and parting. Web in casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during. Web you might like: Web click the image to see all patterns in that category or go straight to the pattern number you are looking for. So the pattern is very critical to the final part. Web the molding system specifies the mounting arrangement of the pattern (as well as often limiting the material choice. Over the past 5 decades,. Foundry patterns for gears were first made of wood and then cast into metal. Web the molding system specifies the mounting arrangement of the pattern (as well as often limiting the material choice. Web wax pattern molding is a specialized technique used in the production of intricate and complex metal components. An explanation of each of these three “tricks” is. Web the molding system specifies the mounting arrangement of the pattern (as well as often limiting the material choice. There are different kinds of patterns depending on the complexity and procedure of casting and molding. Web the sophistication, depth, and style that wall moldings bring to a space are unmatched, turning an ordinary wall into an art piece. It involves. Web the sophistication, depth, and style that wall moldings bring to a space are unmatched, turning an ordinary wall into an art piece. This is achieved by first machining a metal pattern tool, usually from iron. There are various types of patterns used in a foundry. It involves creating a precise wax replica, also known as a. Wax or wood. An explanation of each of these three “tricks” is given below: Following are the different types of pattern used in casting: Web accurate pattern designs and builds plugs and molds for fiberglass composite laminating customers in the aerospace, energy, military, transportation and related industries. Properties and types of moulding sand. Once the initial step of designing and creating the pattern. Web moulding is a design element that adds drama and detail to a room or space. Wax or wood patterns for metal casting. There are a variety of moulding types, shapes, sizes and designs. Web patterns are a fundamental part of the casting process, ensuring that the end products are produced with the desired dimensions and quality. Once the mold is complete, the match plate pattern is removed and the molten metal is poured into the mold cavity. This is an era where individuality. When deciding on types of trim. Over the past 5 decades, we have cultivated. Web patternmaking, in materials processing, the first step in casting and molding processes, the making of an accurate model of the part, somewhat oversize to allow for shrinkage of. Web the match plate pattern is placed in a mold box and the molding sand is packed around it to create the mold cavity. Foundry patterns for gears were first made of wood and then cast into metal. Web in casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process. First, the sand is mixed with a suitable bonding substance. It involves creating a precise wax replica, also known as a. Web plied to foundry patterns to assist mold production and help eliminate casting defects. Web the molding system specifies the mounting arrangement of the pattern (as well as often limiting the material choice.

33 Crown Molding Ideas For Your Home Rhythm of the Home

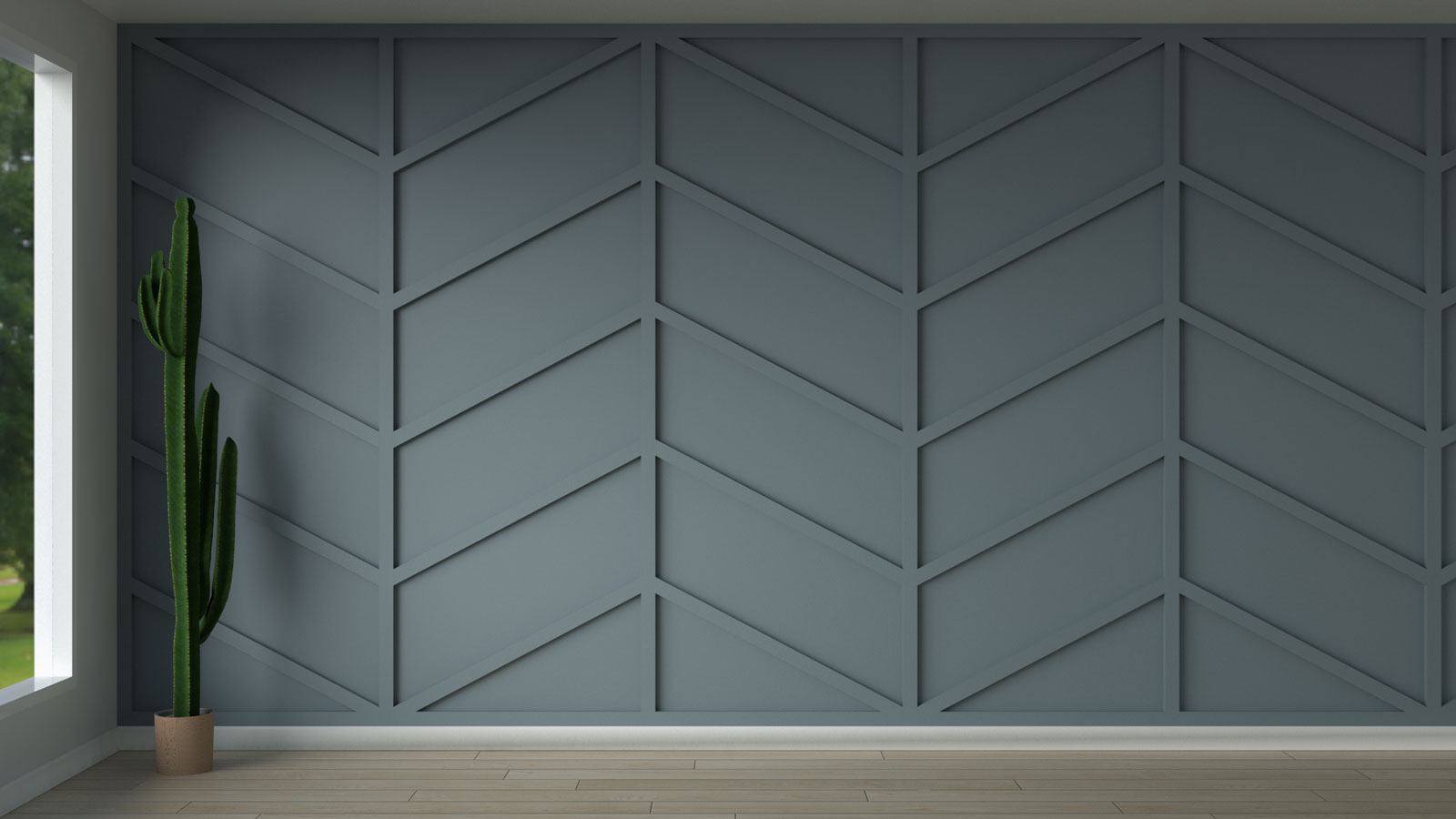

15 Modern Wall Molding Pattern Ideas (Stylish and Trendy Design

Blue Ox Millworks Crown Molding Patterns

Instant Architecture Modern Wall Molding Patterns + Trim Ideas

25 Wall molding patterns. Jenny Patricia

15 Modern Wall Molding Pattern Ideas (Stylish and Trendy Design

15 Modern Wall Molding Pattern Ideas (Stylish and Trendy Design

Blue Ox Millworks Crown Molding Patterns

Molding Ideas North American Architectural Woodwork Standards

15 Modern Wall Molding Pattern Ideas (Stylish and Trendy Design

Web Wax Pattern Molding Is A Specialized Technique Used In The Production Of Intricate And Complex Metal Components.

The First Step In Shell Molding Is Creating A Pattern Part.

The Metal Solidifies And The Match Plate Pattern Is Separated From The Cast Part, Leaving The Desired Metal Object.

Web You Might Like:

Related Post: