Nailing Pattern For Wall Sheathing

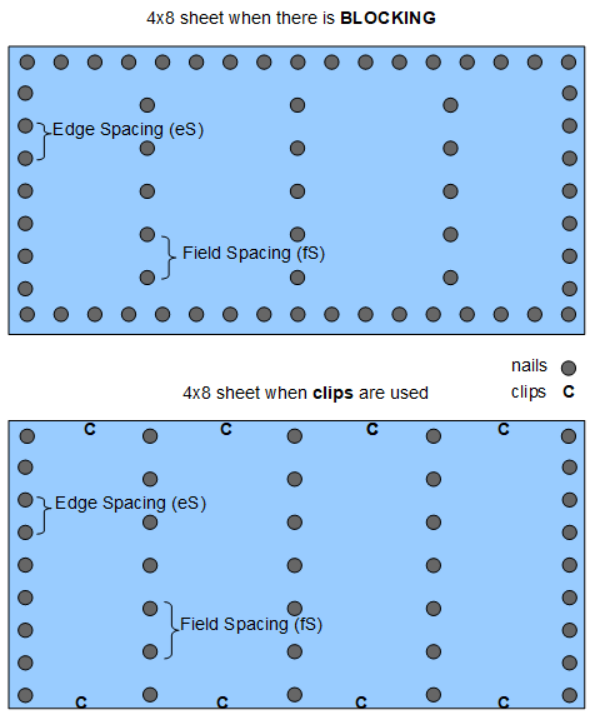

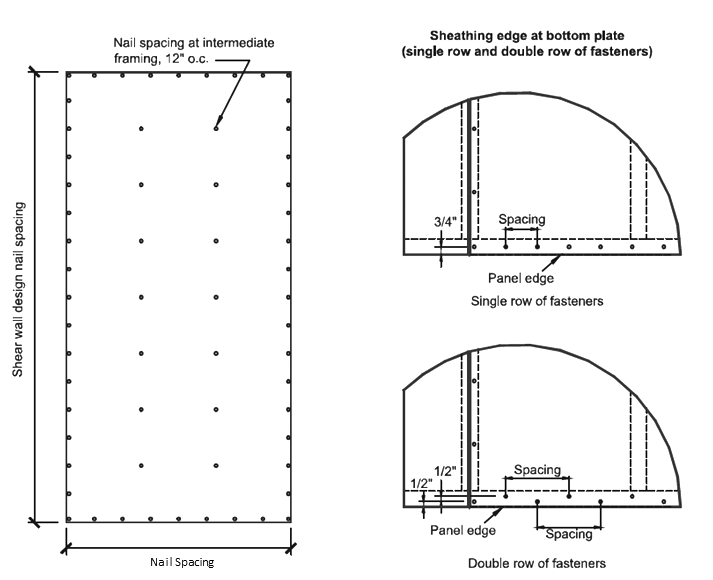

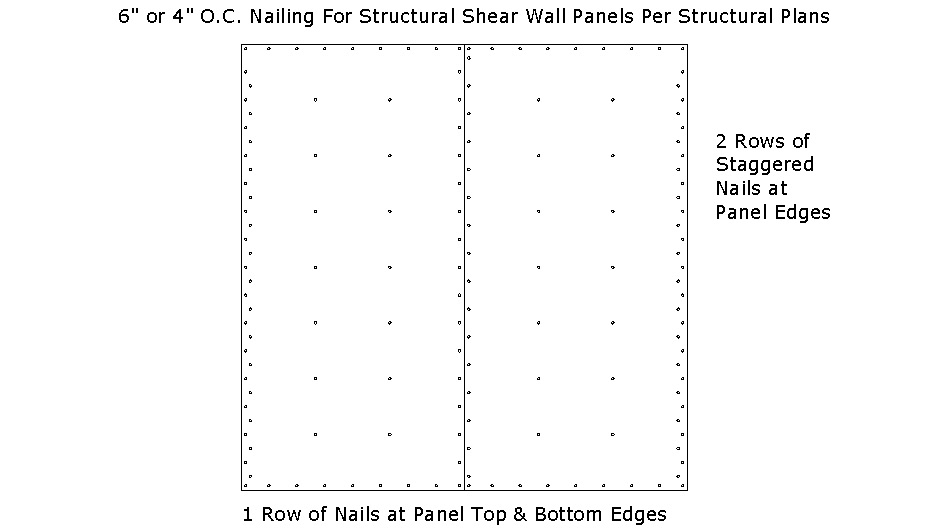

Nailing Pattern For Wall Sheathing - This installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. Web for example, an 8d common nail is 2 1/2 inches (length) x.131 inch (diameter), whereas an 8d box nail is 2 1/2 inches (length) x.113 inch (diameter). Inspect all nail patterns, ensuring they’re set correctly before moving forward. When i order nails for wall sheathing, i don’t order them by penny weight; Choose units and enter the following: Web how to correctly install plywood or osb wall sheathing. Nails or screws, as listed in the fastener chart, may be used to attach densglass sheathing to framing. Web the nails needed for sheathing on a wall calculator computes the approximate number of nails needed to nail 4x8 sheets to wall studs based on the dimensions of the wall, spacing of nails on the edges and field of the 4x8, and whether blocking or clips are use. Eliminates the gable end hinge point when windstorm extends beyond the bottom chord. Web when framing is done and you’re ready to install zip system sheathing on a house, you should first snap a level line on each wall to ensure your first course of panels is straight. When a pneumatic fastening system into metal is used to attach densglass sheathing, consult with manufacturer for application specifications and shear resistance data. Web for example, particleboard wall sheathing to framing requires 6d common or deformed nails measuring 2″ × 0.113″ x 0.266″ head, while wood structural panel exterior wall sheathing to wall framing requires 8d common or deformed nails. Start by holding the corner of each sheet up to the line and setting one nail, and then lift the rest of the panel until it’s lined up and continue nailing. 80 ksi for shank diameter of 0.192 inch (20d common nail), 90 ksi for shank diameters larger than 0.142 inch but not larger than 0.177 inch, and 100 ksi. When a pneumatic fastening system into metal is used to attach densglass sheathing, consult with manufacturer for application specifications and shear resistance data. When i order nails for wall sheathing, i don’t order them by penny weight; Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. There are two common nail patterns. There are two common nail patterns used for roof sheathing: The staggered pattern is a popular. Web wood structural panels, including plywood and osb, are recognized by the building codes for their strength and performance in wall construction. This installation manual covers basic installation recommendations for zip system sheathing when used in both roof and wall applications. At intermediate supports,. Use the nailing lines on the sheets as guides. What’s the permeability of zip system sheathing panels? Nailing the sheathing to the mudsills provides a structural connection between the walls and the foundation. Not 2” or 3” or 4” but 3/8” from the corner. Windstorm lengths are available from 97 1/8″ up to 145 1/8″ in 7/16 and 15/32 thickness. Wipe down the seam areas with a dry rag or use a. The nails should be about 3/8 in. Proper nail patterns distribute the load evenly, preventing sagging, and ensuring a secure roof. Use the nailing lines on the sheets as guides. Instead, i order by the length and diameter. Walls continuously sheathed in plywood or osb also provide an excellent nail base for brick ties, siding and trim. What’s the permeability of zip system sheathing panels? Web for example, an 8d common nail is 2 1/2 inches (length) x.131 inch (diameter), whereas an 8d box nail is 2 1/2 inches (length) x.113 inch (diameter). Web nailing of wall sheathing. Refer to lateral force resisting systems section for screw requirements for shear wall applications. Web installation manual | zip system sheathing and tape. Web no, the integrated protective overlay of a zip system wall sheathing panel is permeable to allow for drying to the outside. Web for example, an 8d common nail is 2 1/2 inches (length) x.131 inch (diameter),. At intermediate supports, fasten panels 12 inches on center. They hold the corner down and keep it from lifting. Nailing the sheathing to the mudsills provides a structural connection between the walls and the foundation. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Angling the nailer helps to ensure the nails. Nails used for framing and sheathing connections shall have minimum average bending yield strengths as shown: Nails or screws, as listed in the fastener chart, may be used to attach densglass sheathing to framing. In typical construction, siding, trim and brick ties are attached to framing members. 80 ksi for shank diameter of 0.192 inch (20d common nail), 90 ksi. When a pneumatic fastening system into metal is used to attach densglass sheathing, consult with manufacturer for application specifications and shear resistance data. Fasteners should be 3/8 inch from panel ends and 3/8 inch from panel. Web for nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. Web we're pushing along on a 3,000sf farmhouse duplex, on a lot that is going to make the building process much more difficult. In typical construction, siding, trim and brick ties are attached to framing members. Instead, i order by the length and diameter. Web the nails needed for sheathing on a wall calculator computes the approximate number of nails needed to nail 4x8 sheets to wall studs based on the dimensions of the wall, spacing of nails on the edges and field of the 4x8, and whether blocking or clips are use. There are two common nail patterns used for roof sheathing: Web wood structural panels, including plywood and osb, are recognized by the building codes for their strength and performance in wall construction. At intermediate supports, fasten panels 12 inches on center. Inspect all nail patterns, ensuring they’re set correctly before moving forward. They hold the corner down and keep it from lifting. Web no, the integrated protective overlay of a zip system wall sheathing panel is permeable to allow for drying to the outside. Use the nailing lines on the sheets as guides. The nails should be about 3/8 in. Nails at the corners must be 3/8” from the corner;

Shear Walls, The Basics JLC Online

Nailing Patterns Common Nailing Schedules & Why They Are So Important

Wall Sheathing Nailing Pattern Timber Structures / Estruturas de Ma…

Nails for Wall Sheathing

Plywood Sheathing Nailing Pattern Nail Ftempo

Plywood Sheathing Nailing Pattern Nail Ftempo

Structural Shear Wall Nailing in Commercial and Residential Framing

Plywood Sheathing Nailing Pattern Nail Ftempo

Nailing Patterns Common Nailing Schedules & Why They Are So Important

Shear Walls, The Basics JLC Online

Windstorm Lengths Are Available From 97 1/8″ Up To 145 1/8″ In 7/16 And 15/32 Thickness Categories.

Web For Example, Particleboard Wall Sheathing To Framing Requires 6D Common Or Deformed Nails Measuring 2″ × 0.113″ X 0.266″ Head, While Wood Structural Panel Exterior Wall Sheathing To Wall Framing Requires 8D Common Or Deformed Nails Measuring 2 1/2″ × 0.131″ X 0.281″ Head.

Web When Framing Is Done And You’re Ready To Install Zip System Sheathing On A House, You Should First Snap A Level Line On Each Wall To Ensure Your First Course Of Panels Is Straight.

Web Least 3/8” (9 Mm) From The Ends And Edges Of The Sheathing.

Related Post: