Nail Pattern For Subfloor

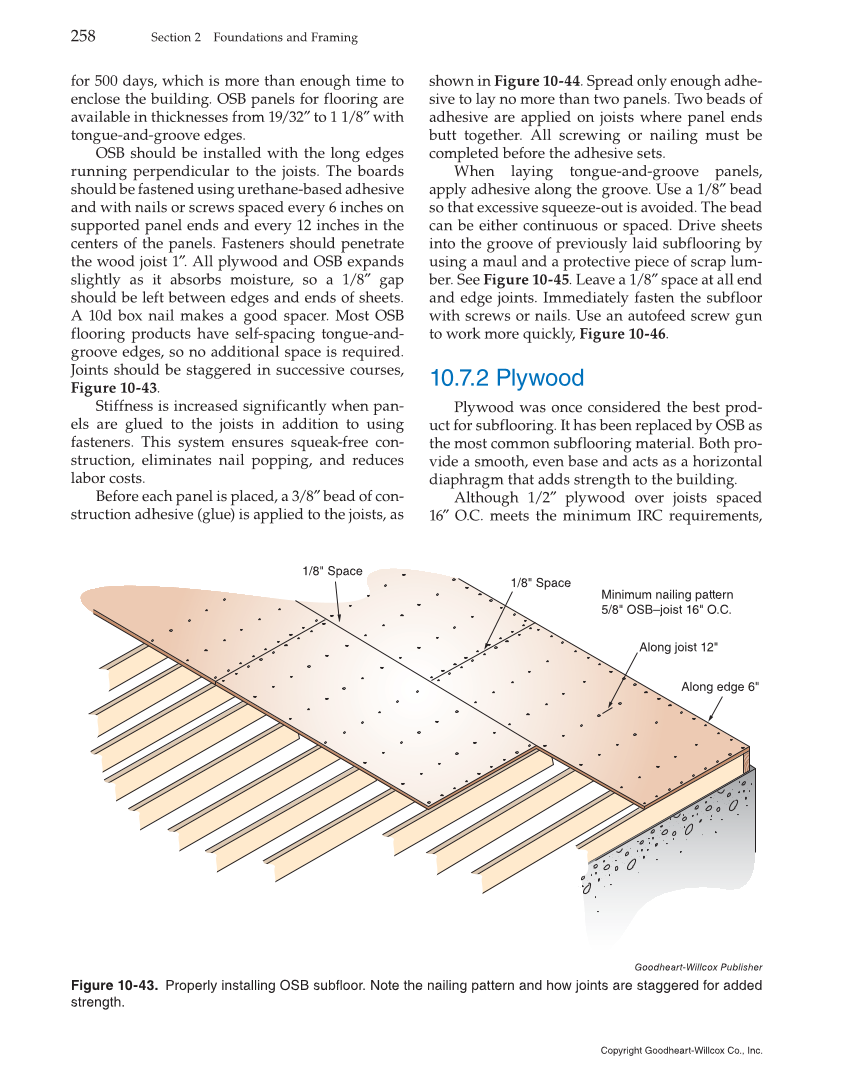

Nail Pattern For Subfloor - Remember not to nail towards the last 10″ of the tongue side. Web nailing down 1/4″ luan. Web as far as nails go, ring shank nails are a popular choice for subflooring. Web the subfloor is nailed and glued, i am not certain as to the nail spacing. I’ve got to fasten down 40 sheets of 1/4″ luan underlayment on monday. So why shouldn’t you just use nails instead of dealing with the hassle of screws? This protects the tongue of next panel from damage when tapped into. Web using nails to install subflooring would be so much faster and easier than using screws. Grip the top panel edge with. Screws are a great alternative that you can easily remove, but they are not as sturdy. • once installed on subfloors, ring shank nails will not back out or break free. So why shouldn’t you just use nails instead of dealing with the hassle of screws? Web wipe any mud, dirt or water from joists before gluing. Lay first panel with tongue side to wall and nail in place. Remember not to nail towards the last. Paulbny | posted in construction techniques on april 5, 2009 03:38am. So why shouldn’t you just use nails instead of dealing with the hassle of screws? • once installed on subfloors, ring shank nails will not back out or break free. However, it is much harder to get. I’ve got to fasten down 40 sheets of 1/4″ luan underlayment on. Web using nails does make installing subfloors faster and easier, and makes it so that you don’t have to really think because of how fast the process is. I’ve got to fasten down 40 sheets of 1/4″ luan underlayment on monday. The second (top) layer of plywood joints should not coincide with the joists and the. Remember not to nail. Web the subfloor is nailed and glued, i am not certain as to the nail spacing. Web nailing down 1/4″ luan. However, it is much harder to get. Nails need to be 8d, spaced every 4 and staggered. Web using nails to install subflooring would be so much faster and easier than using screws. A ring shank has extra grip and holding power, compared to other shank types, and creates a tighter. Lay first panel with tongue side to wall and nail in place. Web as far as nails go, ring shank nails are a popular choice for subflooring. This protects the tongue of next panel from damage when tapped into. Web wipe any. Screws are superior in terms of reducing floor squeaks, but the. Stand the panel vertically with its 4' edge on the floor and the panel face towards you (the staple/nail pattern will be facing you). Web we prefer 2 inch subfloor nails with reverse threads and coated in glue. Web using nails to install subflooring would be so much faster. Remember not to nail towards the last 10″ of the tongue side. Web using nails to install subflooring would be so much faster and easier than using screws. Web to fasten subfloor, use screws or nails specifically designed for subfloor installation. A ring shank has extra grip and holding power, compared to other shank types, and creates a tighter. Stand. This protects the tongue of next panel from damage when tapped into. I’ve got to fasten down 40 sheets of 1/4″ luan underlayment on monday. Screws are superior in terms of reducing floor squeaks, but the. Remember not to nail towards the last 10″ of the tongue side. The second (top) layer of plywood joints should not coincide with the. Nails need to be 8d, spaced every 4 and staggered. To avoid nail pops, pullouts, and shiners (nails that barely hit the joist), all of which can cause squeaks, use the correct nail size and spacing, and ensure the. Web using nails to install subflooring would be so much faster and easier than using screws. I’ve got to fasten down. Paulbny | posted in construction techniques on april 5, 2009 03:38am. A ring shank has extra grip and holding power, compared to other shank types, and creates a tighter. Lay first panel with tongue side to wall and nail in place. The second (top) layer of plywood joints should not coincide with the joists and the. Web this installation manual. Web wipe any mud, dirt or water from joists before gluing. I’ve got to fasten down 40 sheets of 1/4″ luan underlayment on monday. Web using nails to install subflooring would be so much faster and easier than using screws. So why shouldn’t you just use nails instead of dealing with the hassle of screws? Web using nails does make installing subfloors faster and easier, and makes it so that you don’t have to really think because of how fast the process is. This protects the tongue of next panel from damage when tapped into. Stand the panel vertically with its 4' edge on the floor and the panel face towards you (the staple/nail pattern will be facing you). Web we consulted the manufacturer of our floor joists for nailing recommendations. A ring shank has extra grip and holding power, compared to other shank types, and creates a tighter. Remember not to nail towards the last 10″ of the tongue side. • once installed on subfloors, ring shank nails will not back out or break free. Web to fasten subfloor, use screws or nails specifically designed for subfloor installation. Web we prefer 2 inch subfloor nails with reverse threads and coated in glue. Grip the top panel edge with. Web as far as nails go, ring shank nails are a popular choice for subflooring. However, it is much harder to get.

Advantech Flooring Nailing Tips. YouTube

Nailing down a quality hardwood floor with OSB Page 2 of 2

9 Common Subfloor Mistakes—and How to Avoid Them Installing hardwood

88 Hardwood floors nails type Trend in 2021 Flooring and Decor

Phenolic Glue 15mm Underlayment Plywood With Nail Pattern Buy

Plywood Nailing Schedule Nail Ftempo

Advantech Floor Sheathing Nail Patterns & Staggering Sheets 11 YouTube

Plywood Sheathing Nailing Pattern Bios Pics

DAANIS Plywood Subfloor Nailing Schedule

Subfloor nail pattern and nail description (all dimensions in mm

Web This Installation Manual Covers Basic Installation Recommendations For Advantech Subflooring When Used As A Subfloor Panel.

Lay First Panel With Tongue Side To Wall And Nail In Place.

Screws Are Superior In Terms Of Reducing Floor Squeaks, But The.

The Second (Top) Layer Of Plywood Joints Should Not Coincide With The Joists And The.

Related Post: