Metal Casting Pattern

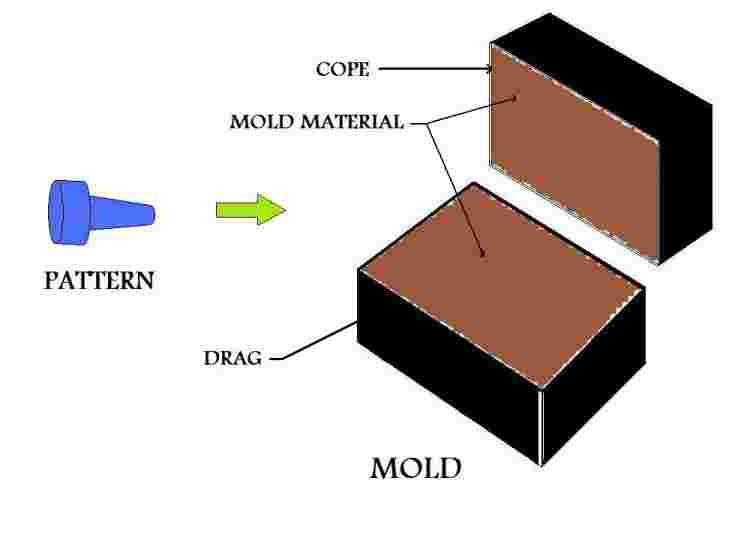

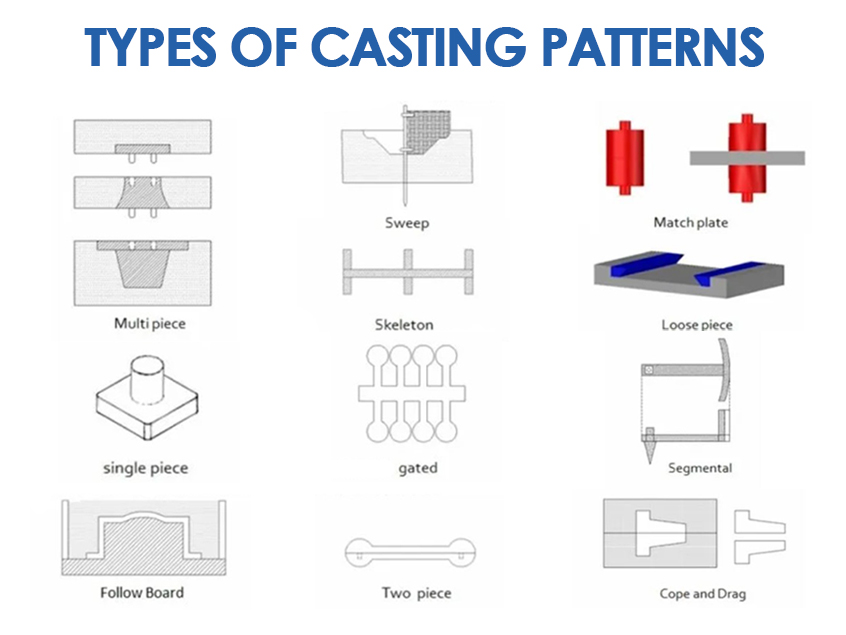

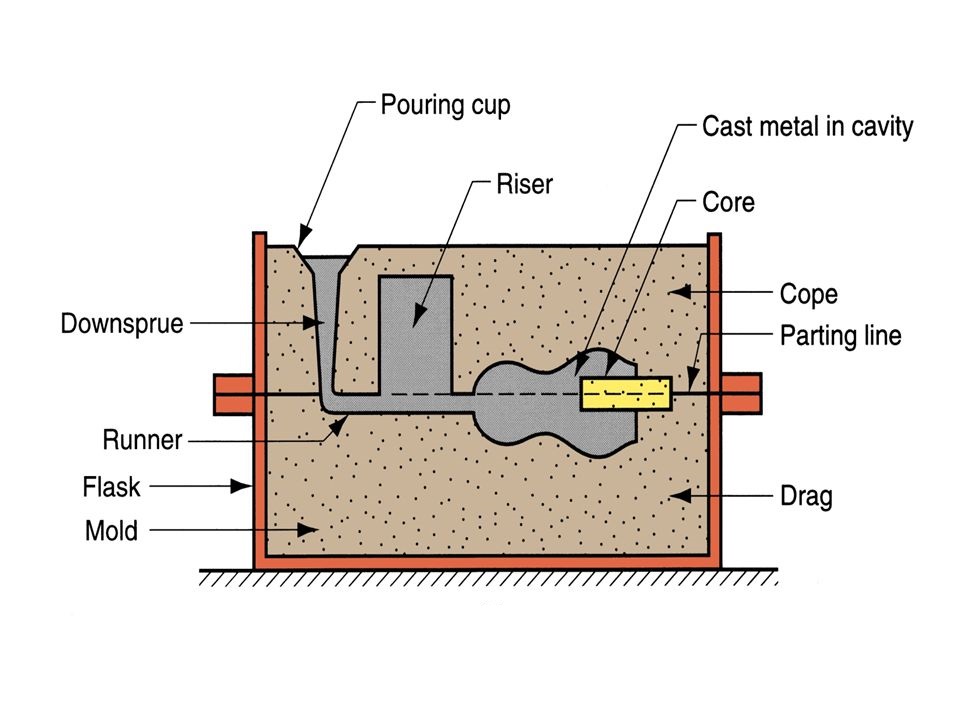

Metal Casting Pattern - Accommodate the characteristics of the metal cast Difference between brazing and soldering [explained] #13 ceramic mold casting. The mold is made from a pattern, which is a replica of the final product. Web making a pattern, also known as an object with a shape like the desired product, is the first step in the metal casting process. Manufacturers coat the cavity, melt the metal, pour it in, and then wait for the metal to solidify. During the process of solidification, a mold must have been designed to suitably place the appropriate sized risers to supply the molten metal into casting. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Once the sand is packed tight, the pattern can be removed and the cast will. This slurry is composed of ethyl silicate hydrolysate and refractory sands, such as fused. This optimization minimizes the defects and ensures consistent quality production of sound castings. Gate pattern can consist of one or more patterns into a pattern molding pattern. Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. A core is a replica, (actually an inverse), of the internal features of the part to be cast. These types of casting process creates castings using a ceramic slurry.. Web because the pattern determines casting form, a casting can be no better than the pattern from which it is made. Most often, metallic patterns are used. Reasons for this are the various design considerations that affect whether the pattern creates a mold that will, in turn, create a product of acceptable. Pattern making is an art in itself, which. Pattern making is an art in itself, which requires a a lot of patience and hard work. Web this kind of casting pattern is widely used in metal casting like aluminum casting. Web for large castings, a special metal pattern is needed, which increases the cost. Gate pattern can consist of one or more patterns into a pattern molding pattern.. This can be achieved using various methods, including cutting, molding, or 3d printing. Difference between brazing and soldering [explained] #13 ceramic mold casting. Pattern making is an art in itself, which requires a a lot of patience and hard work. This optimization minimizes the defects and ensures consistent quality production of sound castings. A pattern is an object that resembles. This is known as metal sand casting. Patterns are larger than the final product and may look somewhat distorted, too. The metal is then poured directly into the mold, which vaporizes the foam upon contact. (ap) — a swiss company will build a plant in georgia to make lightweight parts cast from metal for vehicles and energy generation. Learn to. In casting, a pattern is a replica of the object to be cast, used to form the sand mould. To produce a quality casting, it is essential that the pattern is carefully designed, constructed, and finished. December 23, 2022 by fazfoundry. Web a replica pattern is used to create a mold out of rubber, metal, or resin. This is known. Web for metal castings with internal geometry cores are used. Carlos vasto, president of gf. Web shell molding, also referred to as shell mold casting, is a precise casting process suitable for alloy steel and has six main steps. This is known as metal sand casting. Cores to accommodate holes can be seen in the bottom half of the mould,. This approach, which has roots in antiquity, offers simplicity and economics. Green sand, or molding sand, is packed into the flask around the pattern. To produce a quality casting, it is essential that the pattern is carefully designed, constructed, and finished. It is designed for the mold which makes multiple components in one casting process. Ceramic mold casting ceramic mold. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. Cnc machining is often used to create metal casting patterns. Web the materials most commonly used for sand casting. Web for large castings, a special metal pattern is needed, which increases the cost. Web patternmaking is the initial and critical step in the metal casting process. Web metal casting is a process of shaping molten metal into a desired form by pouring it into a mold. This slurry is composed of ethyl silicate hydrolysate and refractory sands, such as. The main functions of a pattern are to: This approach, which has roots in antiquity, offers simplicity and economics. Web metal casting pattern: During the process of solidification, a mold must have been designed to suitably place the appropriate sized risers to supply the molten metal into casting. The top half of the mould is called the cope. A pattern is a replica of the final product that will be cast, designed to include allowances for shrinkage of the metal during cooling and solidification. Difference between brazing and soldering [explained] #13 ceramic mold casting. Web metal casting is a process of shaping molten metal into a desired form by pouring it into a mold. Web a pattern with a faulty draft angle on vertical surfaces, badly finished corner fillets, or a pattern, which has not been made to an ultra smooth finish will be hard to work with. This slurry is composed of ethyl silicate hydrolysate and refractory sands, such as fused. In metal casting, patterns are used to create the sand molds. The casting process can produce everything from art pieces to engine parts. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. This is known as metal sand casting. Web molding is a multistep process that will form a cast around the pattern using molding sand. Web for metal castings with internal geometry cores are used.

Types of Pattern in Casting Process (Explained in Detail) PDF

Metal Casting Process

Casting Patterns and Patternmaking Metal Casting Blog

An Introduction to Metal Casting Process Stanford Advanced Materials

Metal Casting With Single Sided Patterns.... Two Ways YouTube

Metal Casting Example Problem Casting Pattern design calculations

Casting Patterns Functions, Material, Types, Allowances, Disadvantages

CASTING TERMINOLOGY Bajrang Engineering

3D Printed Patterns For Metal Casting YouTube

handverker sand casting using a 3d print as a pattern for casting in

In Sand Casting, The Split Pattern Enables The Mold To Be Opened And Closed, Making The Process Efficient For Producing A Variety Of Shapes And Sizes.

These Types Of Casting Process Creates Castings Using A Ceramic Slurry.

Patterns Are A Model For The Object To Be Cast.

The Pattern Can Be Made From Various Materials, Including Wood, Plastic, Or Metal, Depending On The Complexity Of.

Related Post: