Lvl Beam Nailing Pattern

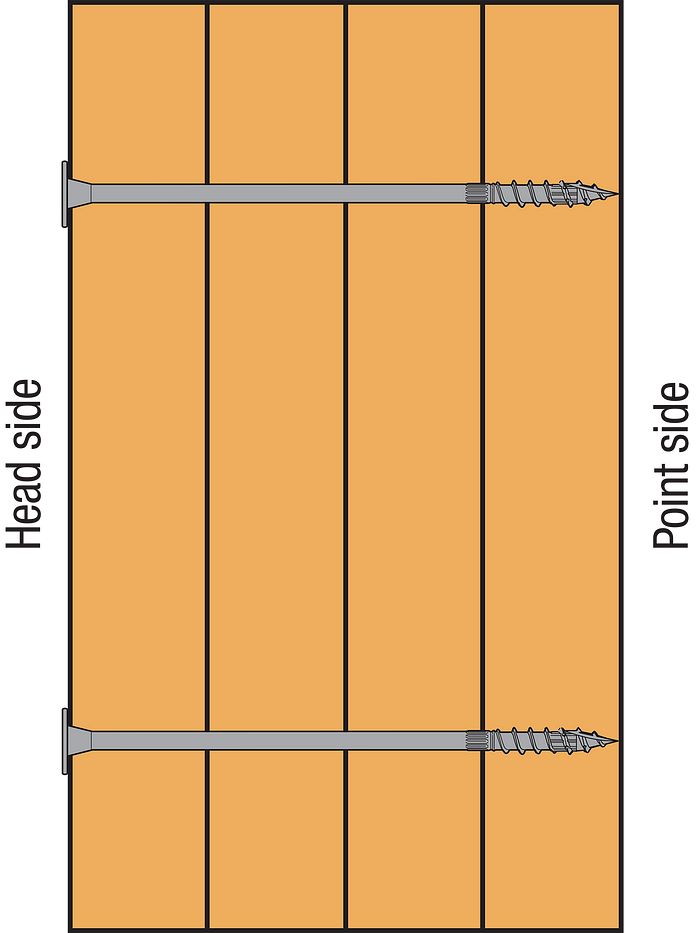

Lvl Beam Nailing Pattern - Hanger must distribute load to each ply of the assembly. Proper preparation, tools, and techniques are essential for attaching lvl beams to posts. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and to. This wide spread market acceptance has been. The following is an allowable load chart for determining the proper. Carefully review and adhere to the design and installation information available from each of the screw. Beams wider than 7 must be designed by the engineer of record. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. Web 16d box nails = 0.135” diameter x 3.5” length, 16d sinker nails = 0.148” diameter x 3.25” length. Find out the recommended nailing pattern,. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. 6) a qualified designer shall ensure the.. Web 16d box nails = 0.135” diameter x 3.5” length, 16d sinker nails = 0.148” diameter x 3.25” length. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. Beams wider than 7 must be designed by the engineer of record. Web. Beams wider than 7 must be designed by the engineer of record. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Hanger must distribute load to each ply of the assembly. Lvl beams are strong, durable, and versatile,. Web the successful design and installation of engineered wood beams such as microllam® lvl, timberstrand® lsl and parallam® psl goes beyond just looking up a. Web (1) where a beam is made up of individual pieces of lumber that are nailed together, the individual members shall be 38 mm or greater in thickness and installed on edge. Web laminated veneer. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. O u r h i. The following. Web laminated veneer lumber (lvl) is widely used in residential housing from bearers and joists through to roof framing elements. Install hanger per manufacturer's instructions. Web (1) where a beam is made up of individual pieces of lumber that are nailed together, the individual members shall be 38 mm or greater in thickness and installed on edge. The following is. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Hanger must distribute load to each ply of the assembly. Web (1) where a beam is made up of individual pieces of lumber that are nailed together, the individual. Hanger must distribute load to each ply of the assembly. Conditions where the loading is not applied evenly across the top of all plies,. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. Microllam® lvl beams work well in applications all. Web (1) where a beam is made up of individual pieces of lumber that are nailed together, the individual members shall be 38 mm or greater in thickness and installed on edge. Web laminated veneer lumber (lvl) • can easily be built up on site to reduce heavy lifting • offers reliable and economical solutions for beam and header applications. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and to. Web from window openings to garage door headers, weyerhaeuser microllam® lvl is a versatile solution that supports heavy loads without worry. O u r h i. Web 16d box nails. Beams wider than 7 must be designed by the engineer of record. Web when sizing beams and headers, you need to have sufficient moment capacity (fb), sufficient shear capacity (fv), sufficient stiffness (ei) to satisfy the live and total load. Web laminated veneer lumber (lvl) is widely used in residential housing from bearers and joists through to roof framing elements. 6) a qualified designer shall ensure the. Web laminated veneer lumber (lvl) • can easily be built up on site to reduce heavy lifting • offers reliable and economical solutions for beam and header applications •. Conditions where the loading is not applied evenly across the top of all plies,. Lvl beams are strong, durable, and versatile, and posts. Hanger must distribute load to each ply of the assembly. O u r h i. The following is an allowable load chart for determining the proper. Web the capacity of the lvl or psl beam may be less and should be checked by a qualified designer or with the manufacturer's literature. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Web from window openings to garage door headers, weyerhaeuser microllam® lvl is a versatile solution that supports heavy loads without worry. Web 16d box nails = 0.135” diameter x 3.5” length, 16d sinker nails = 0.148” diameter x 3.25” length. Carefully review and adhere to the design and installation information available from each of the screw. Web the successful design and installation of engineered wood beams such as microllam® lvl, timberstrand® lsl and parallam® psl goes beyond just looking up a./LaminatedBeamLVL-103307652-56e1ad553df78c5ba0569d46.jpg)

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Find Out The Recommended Nailing Pattern,.

This Wide Spread Market Acceptance Has Been.

Microllam® Lvl Beams Work Well In Applications All Over The House.

Web Joists And Lvl Beams, Along With Weyerhaeuser Rim Board, Are Engineered To Provide Both Strength And Consistency — Features That Help Builders Save On Installation Time And.

Related Post: