Lug Nut Tightening Pattern

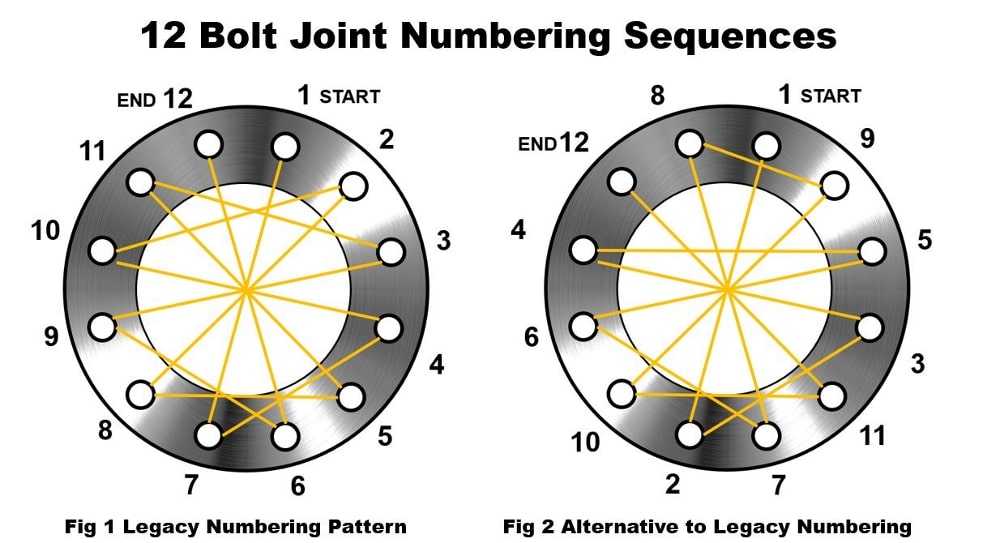

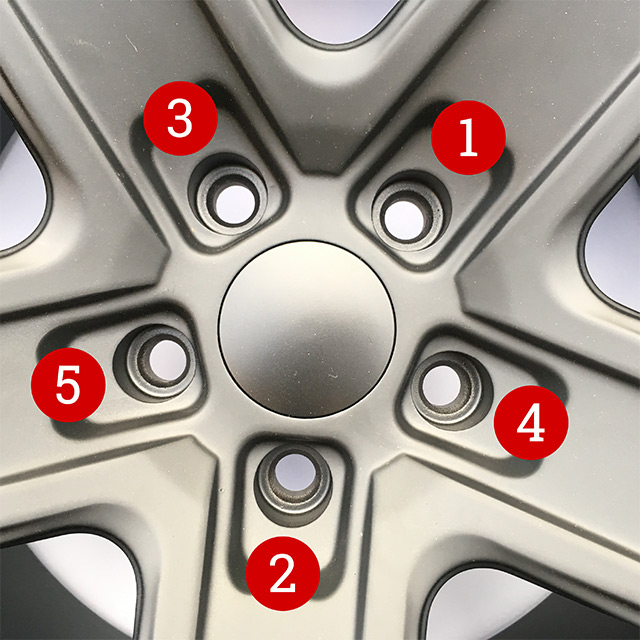

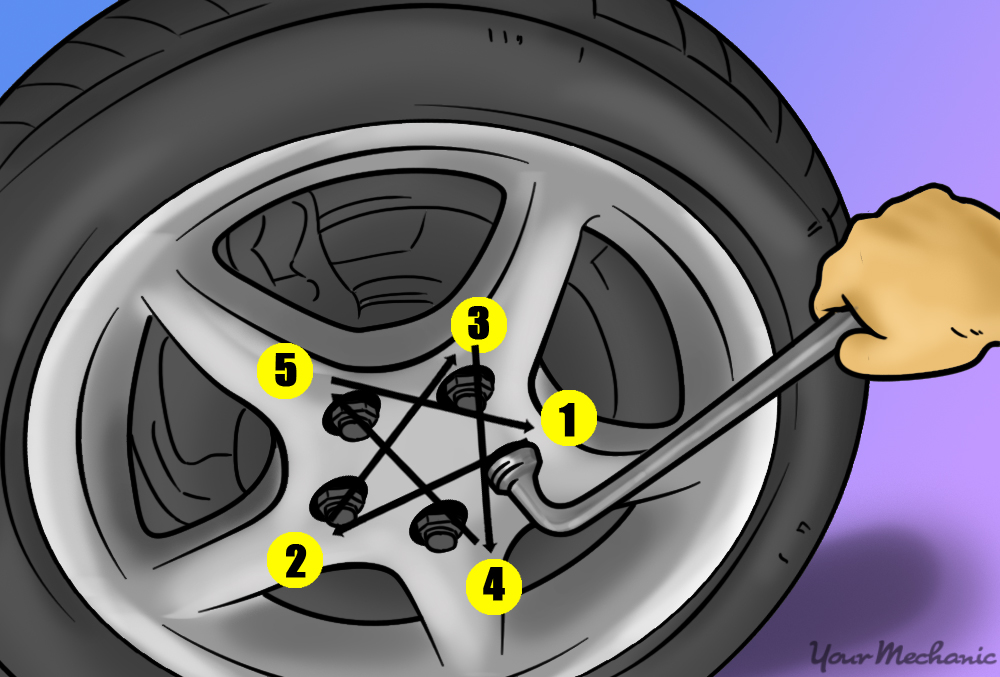

Lug Nut Tightening Pattern - Web after setting the torque wrench to the specification in the owner’s manual or repair manual, there are three steps to tighten lug nuts properly: This will allow you to verify that the lug nuts are the right thread size for the vehicle, and the lugs are safely threading. The friction torque is measured against should come from the hardware seats. Check also that the wheels are in good condition and that the surface where they bolt up to the hub is clean and flat. Have you ever found yourself grappling with those pesky lug nuts during wheel maintenance? Looking at your lug nuts, you wouldn't think how important it. Using the above diagram, tighten your lug nuts in the correct order that corresponds with the number of lug bolts your wheel has. You see when you tighten a single nut, it keeps getting tighter and tighter till the point the wheel mounting face (what you're tightening against) gets stuck to the hub. The first being the number of lug holes, while the second indicates the diameter of the imaginary circle formed by those bolt holes. Make sure that you use a crisscross pattern to tighten and torque the nuts for proper load distribution. Web installing the new wheel stud. Thread a lug nut onto the stud to prevent the stud from slipping out during installation. Don't let this happen to your vehicle! Web 3 wheel security. Knowing how to tighten lug nuts correctly is not just a nifty skill—it’s vital for car safety. Don't let this happen to your vehicle! Web a lug nut tightening pattern, also known as a “star pattern,” is the order in which you should tighten the lug nuts on a wheel. Web this pattern is made up of two numbers: Web remove any rust from exposed threads. Looking at your lug nuts, you wouldn't think how important it. This will allow you to verify that the lug nuts are the right thread size for the vehicle, and the lugs are safely threading. Web this ez to read page shows the wheel (lug) torque sequence for bolt 4, 5, 6 and 8 lug patterns. Fit the new wheel stud into the wheel hub from the rear, aligning it with. Check the studs, nuts, or the bolts for damage being sure that the threads are clean. Web wheel hub damage — threaded wholes stripped out. Use a wire brush to clean the wheel stud and lug nut threads, and then dry them. Get it wrong and you could be in for a rough ride! Install the wheels, ensuring the contact. Then put on the lug nuts and tighten them finger tight. Lubricating hardware threads and seats alters the friction generated at the lug seat, which could result in inaccurate torque application. Replace damaged studs or nuts. If any of the threads are damaged you may need to get a wheel stud replaced or new bolts if that is what you. The friction torque is measured against should come from the hardware seats. A included angle tapered seat lug nut is a very common automotive lug nut design. The torque specification for your vehicle is based on clean dry threads. Web this sequence involves tightening the nuts in a star pattern, alternating between opposite sides to ensure even distribution of torque.. Web here's the secret: Web tightening and loosening patterns. Use a wire brush to clean the wheel stud and lug nut threads, and then dry them. Make sure that you use a crisscross pattern to tighten and torque the nuts for proper load distribution. This pattern is essential for evenly distributing force across the wheel, which helps prevent issues like. Fit the new wheel stud into the wheel hub from the rear, aligning it with the lug holes. Tightening them in a cross pattern reduces the likelihood of things shifting and flexing, which means that your lugs will stay tight after you torque them. Web things can shift underneath even the tightest lug nut or bolt. Web if your car. Web after setting the torque wrench to the specification in the owner’s manual or repair manual, there are three steps to tighten lug nuts properly: Web the proper way to tighten lug nuts. It is also important to tighten lug nuts or bolts incrementally to the final torque specification and doing so in the proper sequence. Web a lug nut. Web a lug nut tightening pattern, also known as a “star pattern,” is the order in which you should tighten the lug nuts on a wheel. Web then the advisor must estimate and recommend the appropriate repair or parts replacement. Follow the tightening and loosening pattern shown below. Web 3 wheel security. Get it wrong and you could be in. Using the above diagram, tighten your lug nuts in the correct order that corresponds with the number of lug bolts your wheel has. Web here's the secret: Web then the advisor must estimate and recommend the appropriate repair or parts replacement. Web things can shift underneath even the tightest lug nut or bolt. Install the wheels, ensuring the contact is even on the mounting surfaces. Don't let this happen to your vehicle! The torque specification for your vehicle is based on clean dry threads. Web installing the new wheel stud. This pattern is essential for evenly distributing force across the wheel, which helps prevent issues like wheel imbalance or warped brake rotors. Web this sequence involves tightening the nuts in a star pattern, alternating between opposite sides to ensure even distribution of torque. Then put on the lug nuts and tighten them finger tight. Web after setting the torque wrench to the specification in the owner’s manual or repair manual, there are three steps to tighten lug nuts properly: Be careful to tighten to the manufacturer's specifications. This pattern will ensure you are tightening your wheels evenly and adequately. Check the studs, nuts, or the bolts for damage being sure that the threads are clean. Follow the tightening and loosening pattern shown below.

Lug Bolt Tightening Sequence And Bolt Torque Chart Method Statement Hq

How to Tighten Lug Nuts YourMechanic Advice

Wheel Bolt Patterns & Typical Lug Nut Torque Specifications Quadratec

How to Change a Tire on an RV? Les Schwab

6 lug tightening sequence World

How To Quickly & Safely Change A Flat Tire Using The CrissCross Lug

How to Diagnose and Repair Noisy Brakes YourMechanic Advice

How to Change a Tire Les Schwab

How to Install New Rotors YourMechanic Advice

/stp-500-481503701-5c4f9fc8c9e77c00014afc8f.jpg)

Wheel Lug Nut Tightening Order by Bolt Pattern

If Any Of The Threads Are Damaged You May Need To Get A Wheel Stud Replaced Or New Bolts If That Is What You Have.

A Included Angle Tapered Seat Lug Nut Is A Very Common Automotive Lug Nut Design.

Knowing How To Tighten Lug Nuts Correctly Is Not Just A Nifty Skill—It’s Vital For Car Safety.

This Is Important Because The Initial Tightening And Driving Can Cause Slight Settling, Resulting In Decreased Torque.

Related Post: