Knurl Patterns

Knurl Patterns - Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Cut knurls tend to be a bit crisper than rolled ones but have some limitations on how they can be applied ie the tool needs to be advanced axially from one end of the knurl as opposed to rolling. Knurling wheel sets are also. The purpose of knurling is to improve the grip or enhance the appearance of the object, making it easier to handle or manipulate by hand. It is mainly used for: A great example of knurling is seen on the thimble of most micrometers. These patterns can consist of straight lines, angles, or interlocking designs. Knurl diamond pattern on the workpiece is equal to the width of the knurl wheel tool depth with standard circular. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. The knurling process enhances the part’s durability and aesthetics while improving its grip. The following table gives standardized diameter pitches and dimensional relationships when producing straight, diagonal, and diamond knurling on cylindrical surfaces having teeth of uniform pitch parallel to the cylinder axis or at a. Here’s a guide to help you differentiate between the different knurl patterns on a bar. Knurling is done to increase the friction on a surface, and is. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface. Web what makes knurl function way different between bars is not just the depth but the pattern of knurl, and there are only a few general types of patterns. The knurling process enhances the part’s durability. Knurling uses the tool to displace material. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. This process creates small ridges along the surface of the metal object so that it can be easily handled. You can now jump into the knurling operation. Web. It’s also affected by the finish that’s applied over the top. The knurling process enhances the part’s durability and aesthetics while improving its grip. The wheels are pressed against the workpiece simultaneously, creating a crisscross pattern. Diagonal, diamond and straight are the three most common patterns generated by knurling wheels. Web knurling is the process of creating a pattern on. It is mostly performed on round or cylindrical parts, but in some cases, is performed on flat surfaces as well. Three common knurl patterns are: The embossed patterns can be decorative, but more often act as hand grips and are commonly seen on handles, knobs or rollers. You can now jump into the knurling operation. Web there are two knurl. Increasing the friction of an area on a part for easier human grip. Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Knurling uses the tool to displace material. For example, a micrometer knob. The wheels are pressed against the workpiece simultaneously, creating a crisscross. Knurling uses the tool to displace material. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. It is mainly used for: The knurling tool is typically mounted in the tool turret of the cnc lathe. It’s also affected by the finish that’s applied over the top. Use a slow speed with a medium feed. Increasing the friction of an area on a part for easier human grip. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. This is achieved by a rotating tool that impressions the desired pattern into the metal. This moving of the. For example, a micrometer knob. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: Web knurling is a machining process that creates a patterned texture on a workpiece's surface, improving grip and aesthetics. It is mainly used for: Web barbell knurling is the crosshatch pattern on the shaft of olympic barbells that is intended to increase friction between your hands and the bar and thus improving grip. Web knurling is the process of creating a pattern on a workpiece to improve the visual appearance or to create a better grip on the part. A great example of knurling. This process creates small ridges along the surface of the metal object so that it can be easily handled. It is mainly used for: Knurl diamond pattern on the workpiece is equal to the width of the knurl wheel tool depth with standard circular. Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Ansi standard knurls and knurling. Web knurling is a manufacturing technique usually conducted on a lathe that involves the production of complex patterns on a component’s surface. Cut knurls tend to be a bit crisper than rolled ones but have some limitations on how they can be applied ie the tool needs to be advanced axially from one end of the knurl as opposed to rolling. Left/right with tips raised, spiral angle: Web knurling is a manufacturing process used to create a textured pattern on the surface of a cylindrical or flat workpiece, typically made of materials like metal, plastic, or wood. Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. In general, knurling operations can act as a repair method. Three common knurl patterns are: This is achieved by a rotating tool that impressions the desired pattern into the metal. This technique produces a more aggressive texture than straight knurling, providing an even more secure grip. Increasing the friction of an area on a part for easier human grip.

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

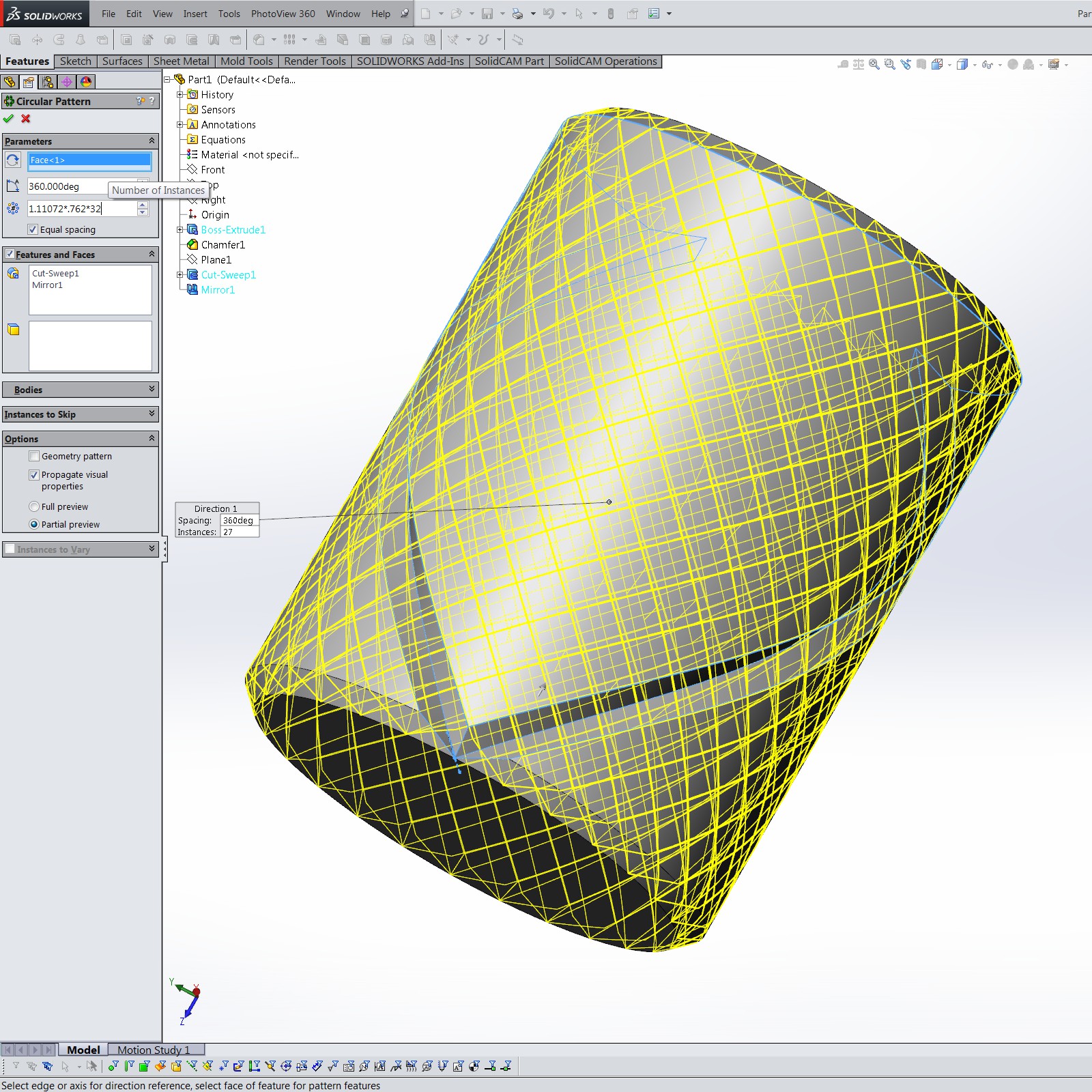

Accurate Knurls in SolidWorks Tom's Maker Site

Knurl Patterns 1000 Free Patterns

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

Knurling designs

Knurling.jpg (720×1200) Patterns & Textures Pinterest Patterns

knurling operation? Purpose of knurling 5 knurl patterns knurling

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

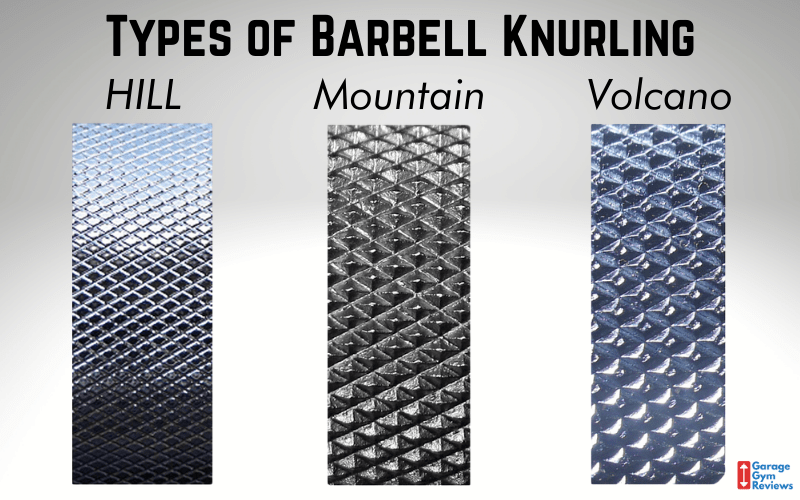

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Knurling designs

The Following Table Gives Standardized Diameter Pitches And Dimensional Relationships When Producing Straight, Diagonal, And Diamond Knurling On Cylindrical Surfaces Having Teeth Of Uniform Pitch Parallel To The Cylinder Axis Or At A.

Knurling Uses The Tool To Displace Material.

It Starts By Determining The Location And Length Of The Knurl And Then Setting The Machine For Knurling.

Use A Slow Speed With A Medium Feed.

Related Post: