Installation Qualification Template

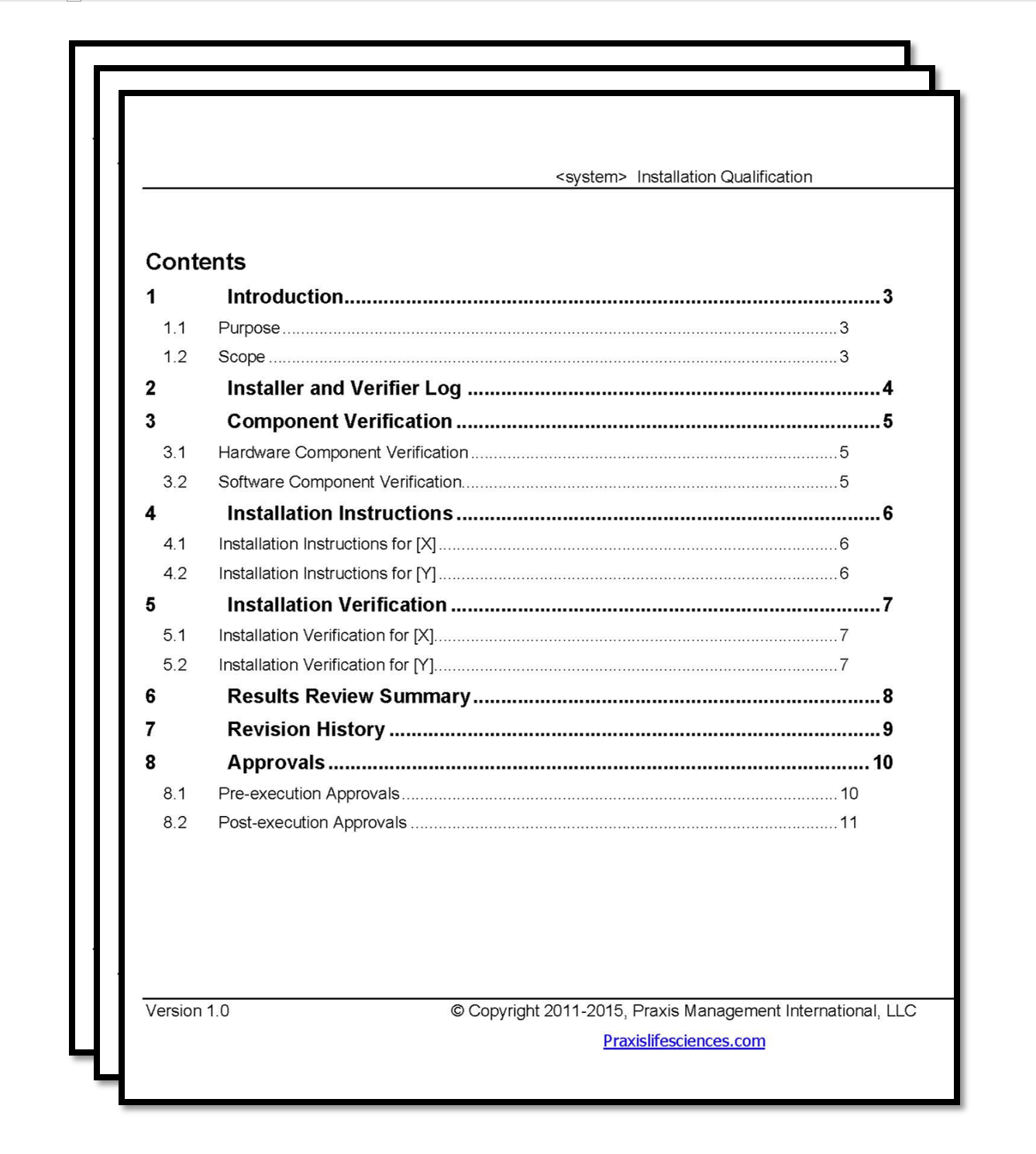

Installation Qualification Template - Web this template describes the required resources and their configuration. Web installation qualification is the documented process that verifies equipment and any parts that comes with it against a checklist of specifications from the. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Oq stands for operational qualification. Web the purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user. It also includes clickup features such. Web the installation qualification ensures the equipment/system and its components are installed correctly according to the original manufacturer’s. This task involves identifying the equipment that needs to undergo installation qualification. For an example of protocol execution, see our fastval electronic protocol execution. Web the purpose of this installation qualification plan for sample is to define the testing activities, expected results, and acceptance criteria for qualifying the installation and. Web installation qualification (iq) is ascertaining that all the important aspects of process equipment together with ancillary system installation follow the approved. Web this template describes the required resources and their configuration. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. Oq stands for operational. Web this installation qualification (iq) details the activities required to execute the iq phase of the qualification of the [equipment/service title] at companyname (shortname). Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. Web the purpose of this installation qualification (iq) protocol is to verify. Web this doc template contains all the necessary sections and content to guide you through the equipment qualification and validation process. Web the purpose of this installation qualification plan for sample is to define the testing activities, expected results, and acceptance criteria for qualifying the installation and. For an example of protocol execution, see our fastval electronic protocol execution. Web. Web this template describes the required resources and their configuration. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. It also includes clickup features such. Web installation qualification. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. Web this template describes the required resources and their configuration. The installation qualification (iq) portion of the protocol was. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. It also includes clickup features such. Oq can be considered a risk assessment step in process validation. Web installation qualification (iq) is ascertaining that all the important aspects of process equipment together with ancillary system installation. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Web the objective of this protocol is to define the installation qualification (iq) and operational qualification (oq) requirements and. Oq stands for operational qualification. Oq can be considered a risk assessment step in process validation. Web the installation qualification ensures the equipment/system and its components are installed correctly according to the original manufacturer’s. Web this doc template contains all the necessary sections and content to guide you through the equipment qualification and validation process. Identify the equipment for installation. Web installation qualification (iq) is ascertaining that all the important aspects of process equipment together with ancillary system installation follow the approved. Web installation qualification is the documented process that verifies equipment and any parts that comes with it against a checklist of specifications from the. Web the purpose of this installation qualification plan for sample is to define the. Web this doc template contains all the necessary sections and content to guide you through the equipment qualification and validation process. It also includes clickup features such. The deviation was investigated and closed off. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. For an. This task involves identifying the equipment that needs to undergo installation qualification. It plays a crucial role in. Web the installation qualification ensures the equipment/system and its components are installed correctly according to the original manufacturer’s. Oq stands for operational qualification. For an example of protocol execution, see our fastval electronic protocol execution. Web the purpose of this installation qualification plan for sample is to define the testing activities, expected results, and acceptance criteria for qualifying the installation and. Web this doc template contains all the necessary sections and content to guide you through the equipment qualification and validation process. The installation qualification (iq) portion of the protocol was written, executed, and approved to ensure that the system, composed of both. Web installation qualification (iq) is ascertaining that all the important aspects of process equipment together with ancillary system installation follow the approved. Web for more examples, see our installation qualification template. It also includes clickup features such. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as. Web installation qualification is the documented process that verifies equipment and any parts that comes with it against a checklist of specifications from the. Identify the equipment for installation qualification. Web the objective of this protocol is to define the installation qualification (iq) and operational qualification (oq) requirements and acceptance criteria for the [insert system name. Web an installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as.

IQ / OQ Installation / Operation Qualification Protocol PDF Download

Installation Qualification IQ Procedure

(PDF) Installation Qualification Template · Installation Qualification

Automating the Installation Qualification (IQ) Step to Expedite GxP

Installation Qualification Format Checklist YouTube

Installation Qualification Template

Template For Installation Qualification Protocol Pharmaceutical

5 Domestic Electrical Installation Certificate Template 62670

Installation Qualification (IQ) Template Validation Center

Contractor’s qualification statement form in Word and Pdf formats

Web This Template Describes The Required Resources And Their Configuration.

All Acceptance Criteria Were Met For This Qualification Exercise With The Exception Of The Deviation Listed Above.

Oq Can Be Considered A Risk Assessment Step In Process Validation.

The Deviation Was Investigated And Closed Off.

Related Post: