In Investment Casting The Pattern Is Made Of

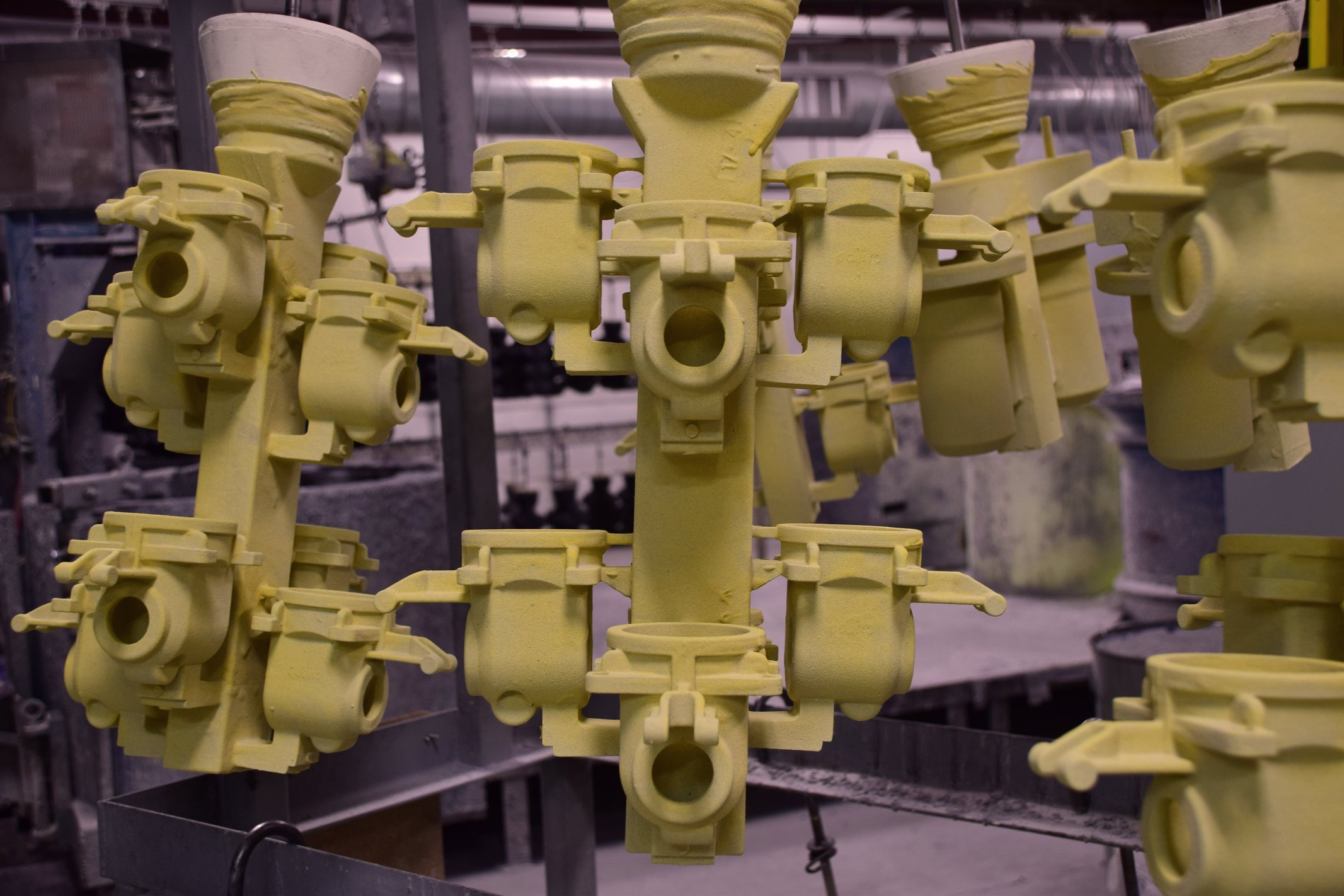

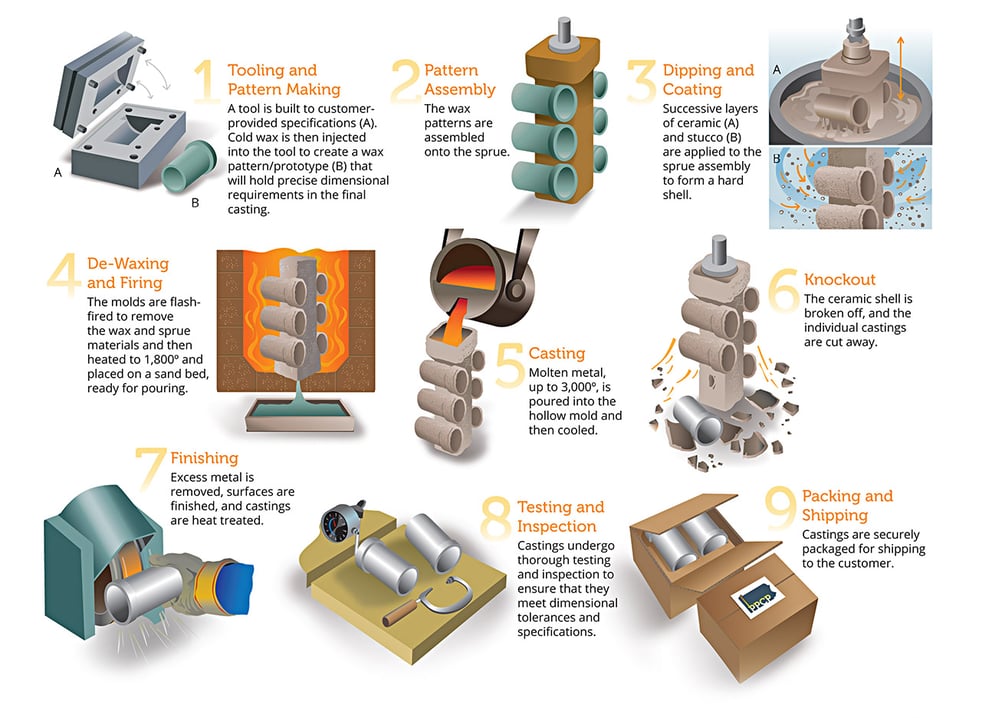

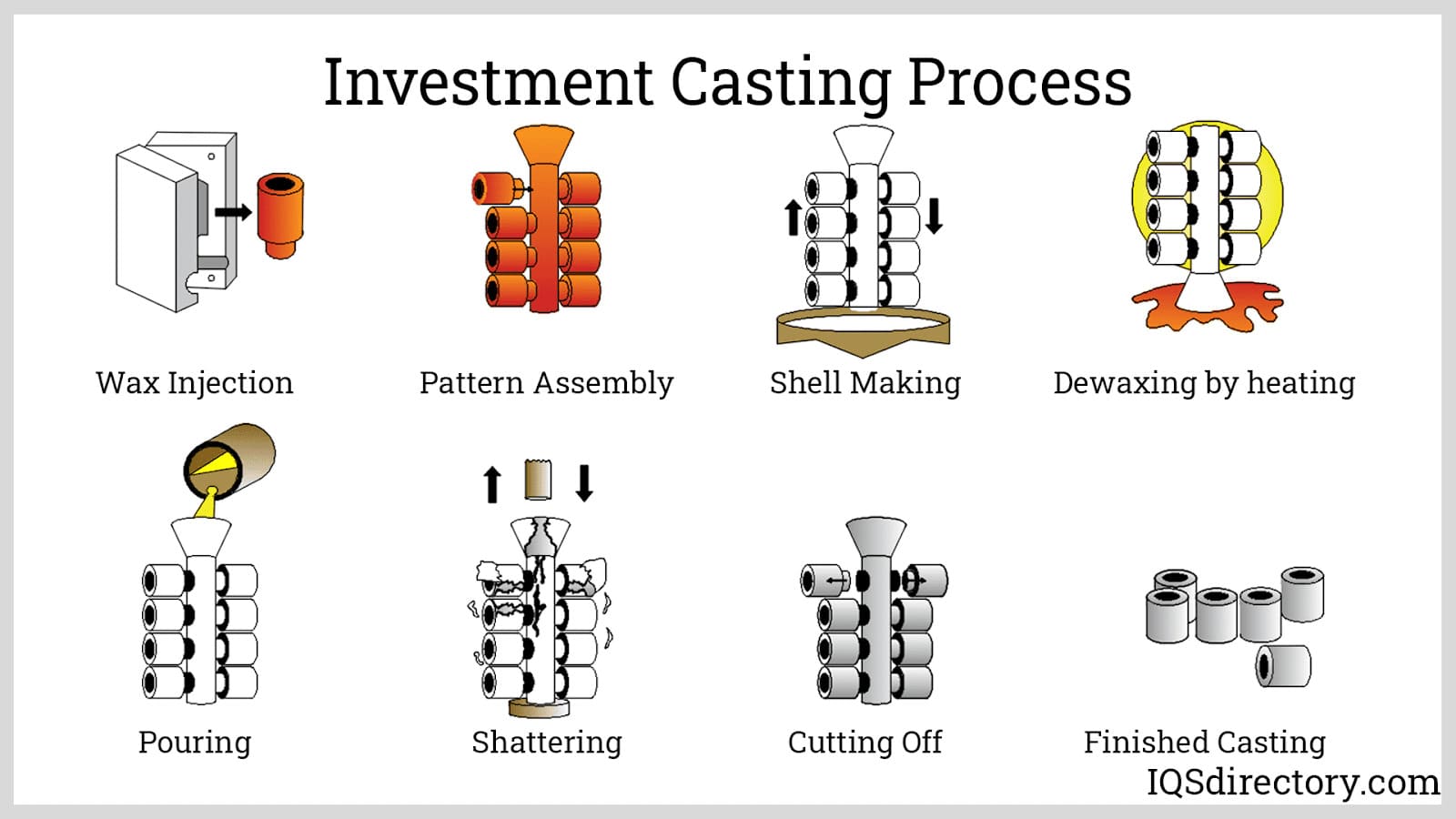

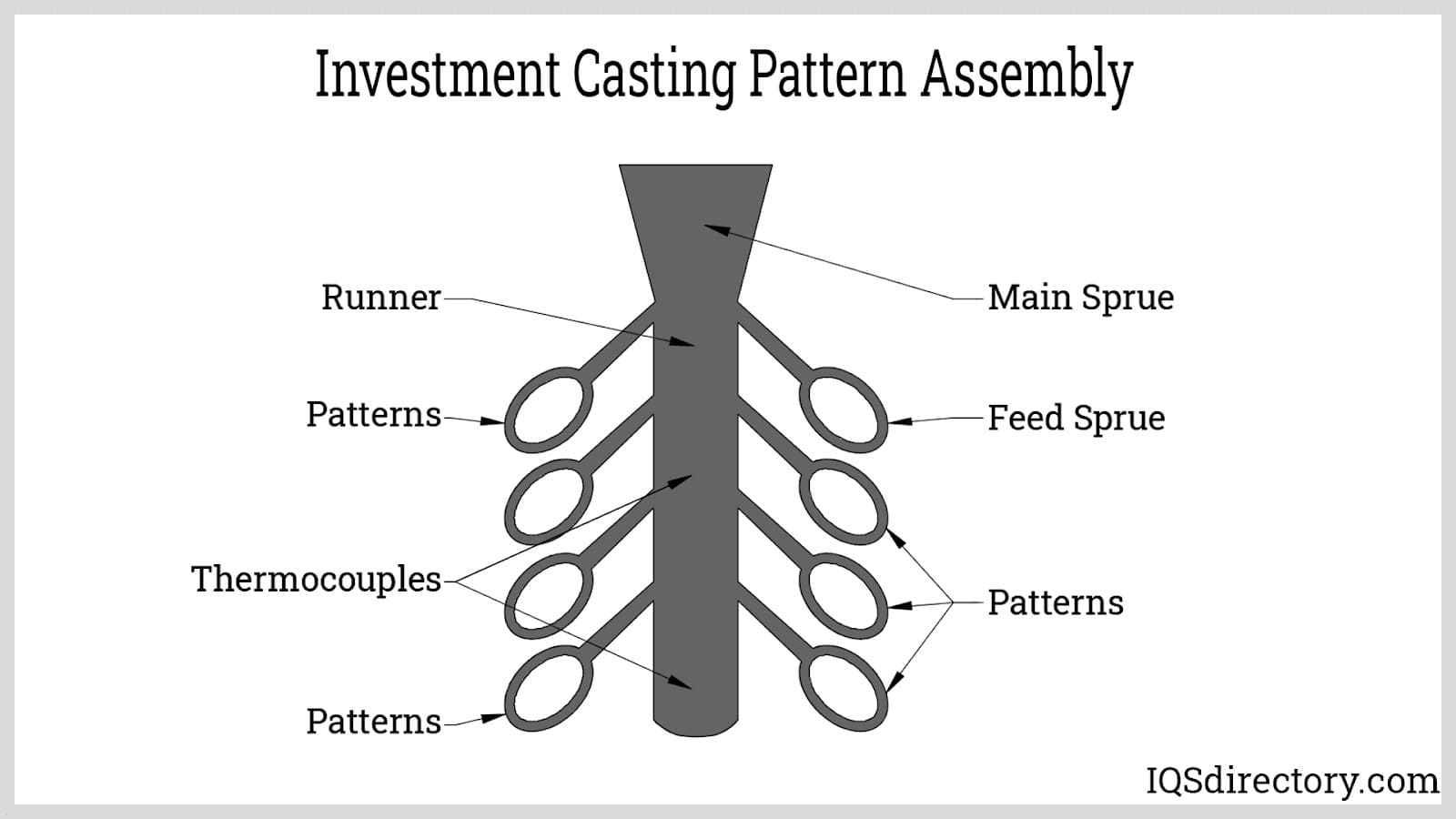

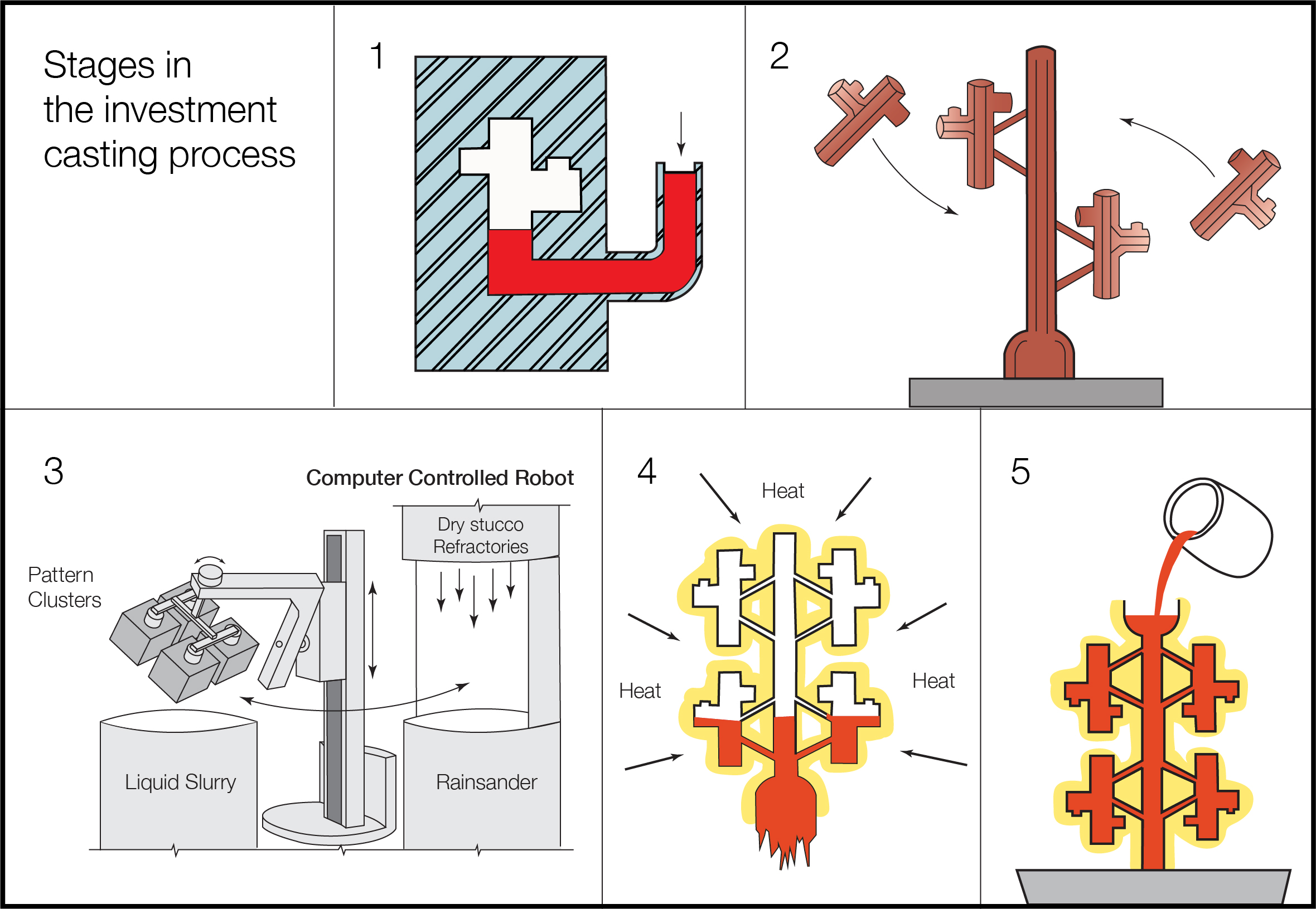

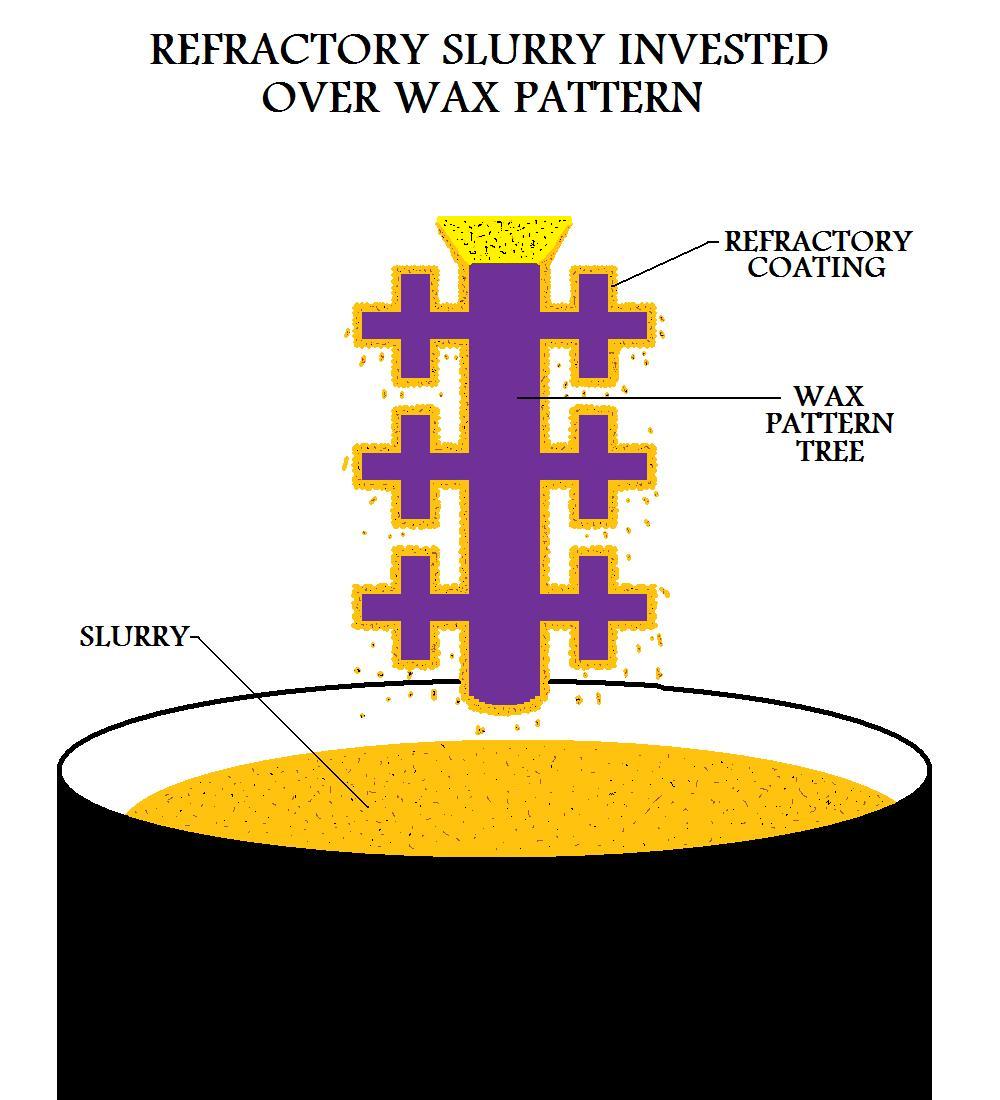

In Investment Casting The Pattern Is Made Of - Web investment casting is a type of casting process by which highly complex parts can be quickly made (to learn more about casting, read our article on the types of casting processes). Web investment casting is a metalworking process that uses a ceramic shell built over a wax pattern to produce parts with extraordinarily uniform and smooth surfaces. Web a temporary initial pattern is made from wax. Web as per their presentation, in the investment casting technique, a pattern of the desired shape, usually made of wax, is formed by injecting molten wax into a metallic die. They can be cast with high precision and an excellent surface finish. Once the ceramic material is hardened its internal geometry takes the shape of the casting. Web an overview of the investment casting process. Plaster, sand investment casting is also known by which one of the following names The more complicated the shape (because of undercuts, for example), the more costly the metal dies. Web investment casting is a type of casting technique that is used to make metal parts with complex shapes. The main steps of the investment casting process are. Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means. In investment casting, a wax or suitable polymer pattern is coated by dipping into the refractory material slurry. Web investment casting is a metalworking process that uses a ceramic. Investment casting is a process where metal is heated and poured into molds. The wax pattern is melted and removed in a furnace and metal is poured into the shell to create the casting. Web the mold in investment casting is made of which two of the following materials: Web investment casting is a type of casting technique that is. Web investment casting is a metalworking process that uses a ceramic shell built over a wax pattern to produce parts with extraordinarily uniform and smooth surfaces. Finishing can be done by hand, but in many cases it is automated. The first step of investment casting is to make the master prototype made of wax. The wax pattern is produced from. Web there are different types of patterns, but they fall into two major subtypes: Industrial applications typically involve some degree of machining, but artisans can also do this step by hand. Reusable ones for sand or plaster casting, which make impressions into many molds, or expendable patterns for investment casting, that are destroyed before casting during the process of making. The main steps of the investment casting process are. The wax pattern is covered with a ceramic layer, from which the wax is removed. Web investment casting forms the cavity by drying and then kiln baking a skin of refractory material over a pattern or master that is sacrificial. Web in investment casting ( figure 6.5 ), a metal die. The wax pattern is produced from an aluminum die. Crating wax pattern is the first step of investment casting mold for investment casting manufacturers and also the basis of the precision investment casting process. This process is repeated until the required wall thickness is achieved. The metal casting process starts with making a pattern or prototype of the desired part.. There are four main steps to the investment casting processes, shown in figure 1, and explained below. The wax pattern is produced from an aluminum die. Web a temporary initial pattern is made from wax. Web in investment casting, a wax pattern is coated with a refractory material to make a mould, which is then melted away before pouring molten. After the mold is formed, wax is injected to form a pattern. Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means. Web investment casting employs a shell made of ceramic, plaster, or plastic that is formed around a wax pattern. It is known for its ability to. Materials that can be cast include stainless steel alloys, brass, aluminium, carbon steel and glass. What is investment casting used for? Web the mold in investment casting is made of which two of the following materials: The metal casting process starts with making a pattern or prototype of the desired part. Precision and extent of detail differ greatly between casting. This process is repeated until the required wall thickness is achieved. Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means. After the mold is formed, wax is injected to form a pattern. Web investment casting is a type of casting process in which an expendable pattern is. Web investment casting pattern. Once the ceramic material is hardened its internal geometry takes the shape of the casting. Web investment casting is a metalworking process that uses a ceramic shell built over a wax pattern to produce parts with extraordinarily uniform and smooth surfaces. In investment casting, a wax or suitable polymer pattern is coated by dipping into the refractory material slurry. Web investment casting is so named because the process invests (surrounds) the pattern with refractory material to make a mould, and a molten substance is cast into the mold. It is widely used in jewelry (other techniques are also common) but also for the manufacture of turbine blades for jet engines. Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means. Web investment casting is a manufacturing process in which a wax pattern is coated with a refractory ceramic material. Web a temporary initial pattern is made from wax. What is investment casting used for? Web investment casting employs a shell made of ceramic, plaster, or plastic that is formed around a wax pattern. Web investment casting is a type of casting process in which an expendable pattern is employed, for instance, made of wax. Web in investment casting, a wax pattern is coated with a refractory material to make a mould, which is then melted away before pouring molten metal into the cavity to solidify. There are four main steps to the investment casting processes, shown in figure 1, and explained below. The main steps of the investment casting process are. Then the pattern or a cluster of such patterns are gated together to.

How the Investment Casting Process Works

Investment Casting vs. Die Casting 7 Considerations When Choosing a

Lost Wax Casting What Is It? How Does It Work? Parts, Metal

Investment Casting What Is It? How Does It Work? Uses

Pattern Assemby Investment Casting Process YouTube

Investment Casting Monmet

Investment Casting

Investment Casting Patterns Quickparts

The future of investment casting? 3D printing PMMA patterns

Investment Casting Process Investment Casting of Metal Parts

The Wax Pattern And Ceramic Mold Are Destroyed During The Investment Casting Process, So Each Casting Requires A New Wax.

The First Step Of Investment Casting Is To Make The Master Prototype Made Of Wax.

Web Investment Casting Is A Type Of Casting Process By Which Highly Complex Parts Can Be Quickly Made (To Learn More About Casting, Read Our Article On The Types Of Casting Processes).

Industrial Applications Typically Involve Some Degree Of Machining, But Artisans Can Also Do This Step By Hand.

Related Post: