Header Nailing Pattern

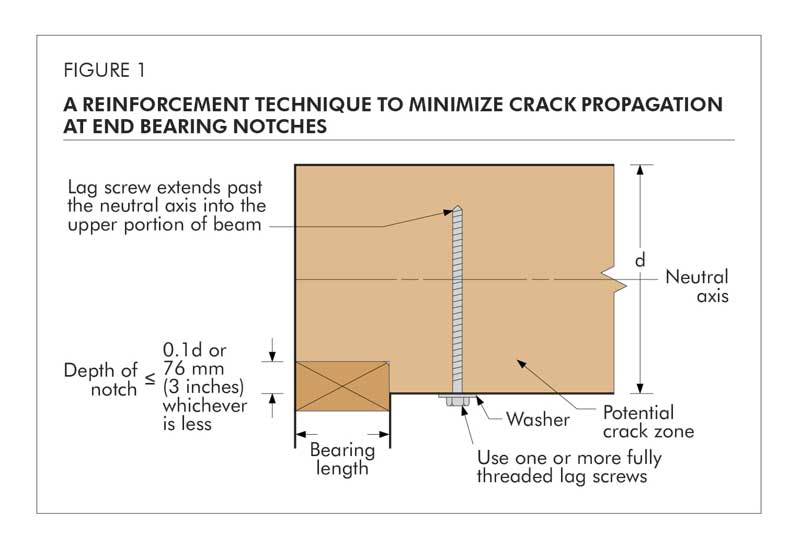

Header Nailing Pattern - He also discusses several alternative designs to the double 2×12 and when they are appropriate: Flip header and repeat the inverse on the other side. Web lumber manufacturers will often have nailing pattern for beams (same thing really). Filler and backer block dimensions should accommodate required nailing without splitting. For fast, accurate installation of door and window headers and other cross members. Web if you’ve ever installed shingles, plywood, headers or drywall, you probably already know all about nailing patterns. Now, your attachment to your posts is critical, so fill us in with more information and/or pictures if you can. A magnetic nail holder is incorporated into the head to help you start nails with one hand when you’re stretched out on a ladder. Web the fastest an easiest way is to sandwich and nail together the headers without any plywood or insulation. Nailing schedule is most always limited to three 16's every 16, nailed from both sides. He also discusses several alternative designs to the double 2×12 and when they are appropriate: For nailing of wood structural panel and particleboard diaphragms and shear walls, refer to section 2314.3. If 2 x 6 studs are to be used for the wall construction, another layer of plywood and an additional header board are used to bring the total thickness. Web use your framing nail gun to nail the header together, making sure to use enough nails to hold it securely. If 2 x 6 studs are to be used for the wall construction, another layer of plywood and an additional header board are used to bring the total thickness of the header to 5 ½ inches. Web if you’ve. Web lumber manufacturers will often have nailing pattern for beams (same thing really). Flip header and repeat the inverse on the other side. Web i was wondering what the common nailing pattern is when laminating two 2x8s. Web that pattern is generally followed ever 12in. Web if you’ve ever installed shingles, plywood, headers or drywall, you probably already know all. Now, your attachment to your posts is critical, so fill us in with more information and/or pictures if you can. Just nail the header flush to the outside of the wall and let the insulator install the insulation on the inside. Web take a deeper look into the proper quantity, placement, and techniques for nailing wall assemblies together with different. Web use your framing nail gun to nail the header together, making sure to use enough nails to hold it securely. I've yet to see one specified with bolts unless there was a flitch plate or something else off the beaten path going on. Web that pattern is generally followed ever 12in. Properly nailed frames distribute the load evenly, enhancing. Web i frequently frame new homes with 2x12 built up girders for the main beams in the basement. Just nail the header flush to the outside of the wall and let the insulator install the insulation on the inside. Nail from both sides of the header to sandwich the boards together. Two/three nails on the end depending on board size,. A magnetic nail holder is incorporated into the head to help you start nails with one hand when you’re stretched out on a ladder. Simpson strong tie sells special screws for beam building.rated for shear forces. Web i drew up this portal frame detail to show the nailing pattern per code so that a person with little or no construction. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and to disperse the naturally occurring characteristics of wood, such as knots, that can weaken a sawn lumber beam. Solid sawn lumber header and girder spans for the exterior bearing walls reduce. Two/three nails on the end depending on board size, then 1 nail every 12 alternating top and bottom. Web use your framing nail gun to nail the header together, making sure to use enough nails to hold it securely. For fast, accurate installation of door and window headers and other cross members. Web lumber manufacturers will often have nailing pattern. Web lp solidstart lvl is made from ultrasonically and visually graded veneers that are arranged in a specific pattern to maximize the strength and stiffness of the veneers and to disperse the naturally occurring characteristics of wood, such as knots, that can weaken a sawn lumber beam. Flip header and repeat the inverse on the other side. I think 2. The nailing pattern will be determined by the engineer. Two/three nails on the end depending on board size, then 1 nail every 12 alternating top and bottom. He also discusses several alternative designs to the double 2×12 and when they are appropriate: Nail from both sides of the header to sandwich the boards together. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that critical. I've yet to see one specified with bolts unless there was a flitch plate or something else off the beaten path going on. Hh header hangers can speed up the job, strengthen the frame and eliminate the need for trimmers. Be sure to nail through the plywood strips. Web when securing 2 or more dimensional wood boards together to form a beam you will need to use the proper number and size nails to create a solid member. If 2 x 6 studs are to be used for the wall construction, another layer of plywood and an additional header board are used to bring the total thickness of the header to 5 ½ inches. Suggested minimum length is 24 for filler and 12 for backer blocks; Web the nailing pattern mentioned by neal is correct. Web if you’ve ever installed shingles, plywood, headers or drywall, you probably already know all about nailing patterns. For fast, accurate installation of door and window headers and other cross members. Simpson strong tie sells special screws for beam building.rated for shear forces. Web i frequently frame new homes with 2x12 built up girders for the main beams in the basement.

How to Make a Nail Header YouTube

Nailing Pattern For Lvl Beam Nail Ftempo

2X10 Beam Nailing Pattern New Images Beam

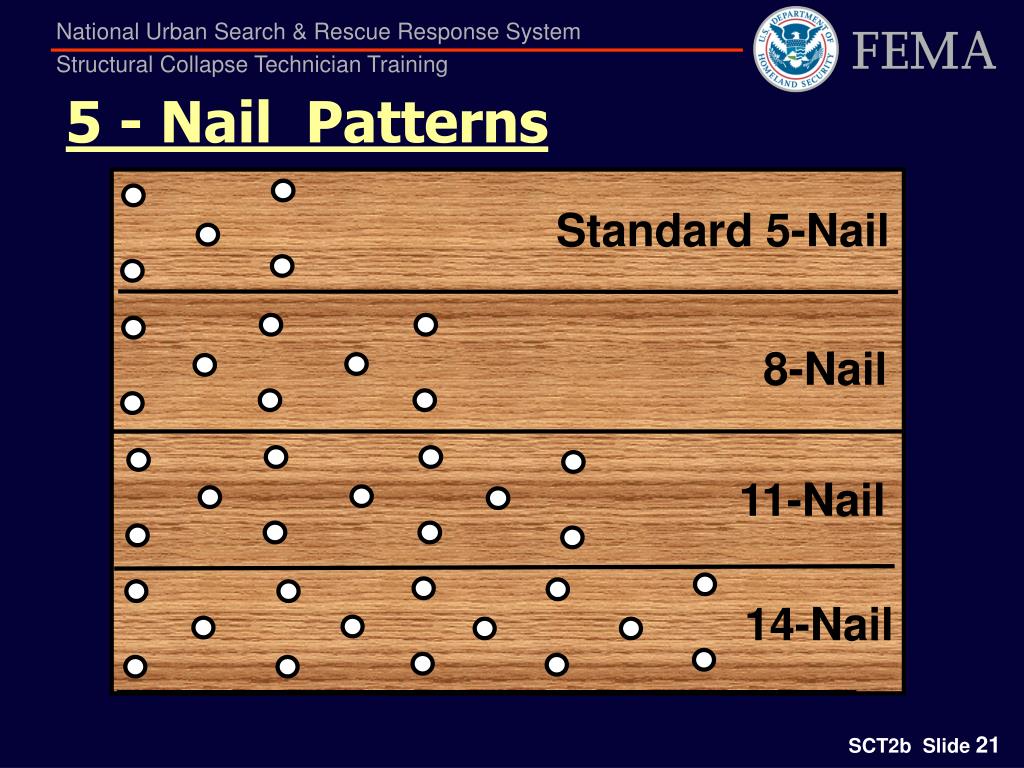

PPT Structural Collapse Technician Training Ver. 3.1 PowerPoint

Nailing Pattern For Lvl Beam Nail Ftempo

2X12 Beam Nailing Pattern The Best Picture Of Beam

Napa Guidelines Plywood Nailing Bay Area Retrofit

Beam layout and nailing patterns. YouTube

/LaminatedBeamLVL-103307652-56e1ad553df78c5ba0569d46.jpg)

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Patterns Common Nailing Schedules & Why They Are So Important

Now, Your Attachment To Your Posts Is Critical, So Fill Us In With More Information And/Or Pictures If You Can.

Web Nails Spaced At 6 Inches (152 Mm) On Center At Edges, 12 Inches (305 Mm) At Intermediate Supports Except 6 Inches (152 Mm) At All Supports Where Spans Are 48 Inches (1219 Mm) Or More.

For Nailing Of Wood Structural Panel And Particleboard Diaphragms And Shear Walls, Refer To Section 2314.3.

Properly Nailed Frames Distribute The Load Evenly, Enhancing The Longevity Of The Structure.

Related Post: