Gdt Pattern Of Holes

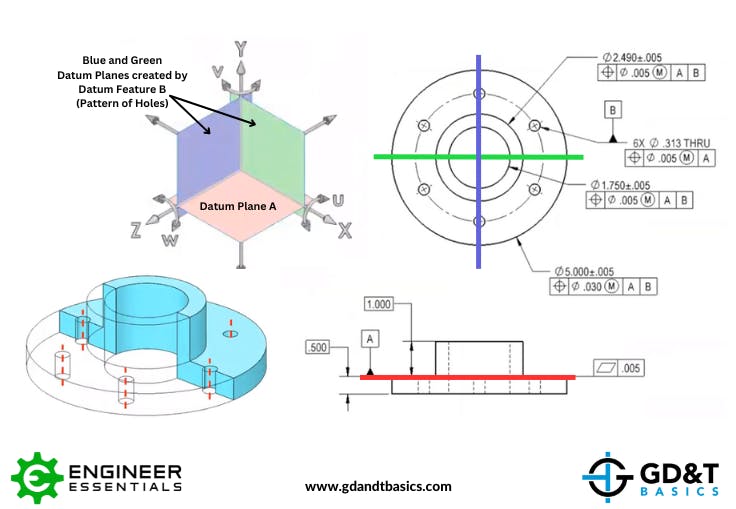

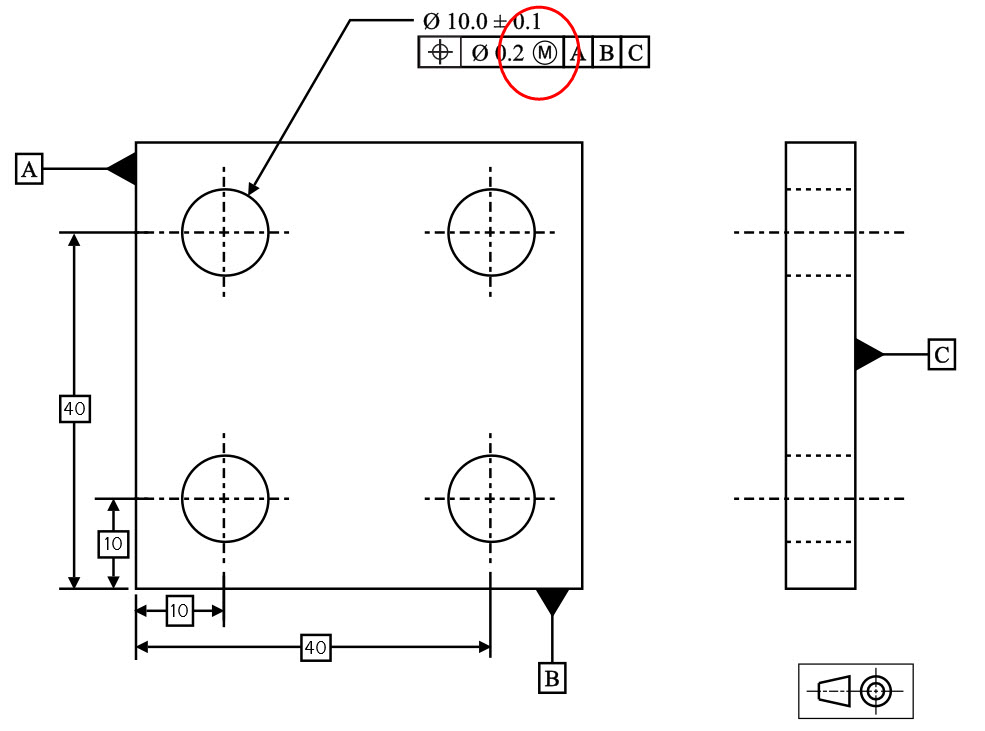

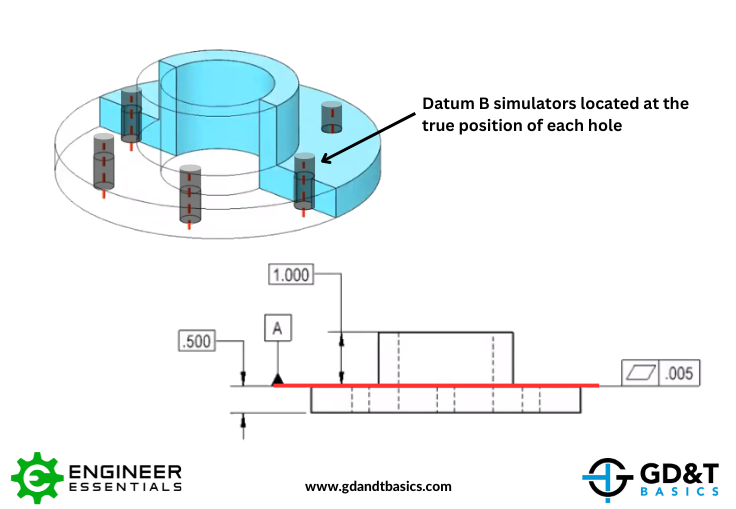

Gdt Pattern Of Holes - Flanged part with a pattern of bolt holes. We are now making this available to eve. Web using one of the holes as a datum, has the advantage that it translates more directly into an inspection procedure. Web true position = 2 x sqrt (xvar^2 + yvar^2) so, we take the difference in x (difference between actual and measured x), square it, add that to the difference in y squared, take the square root of that sum and multiply by 2. Let’s have a look at this simple plate with six holes in figure 1 and see how they are dimensioned. It's really another virtual condition, but when it's applied to a datum feature of size all of the cool gd&t geeks call it a max material boundary. This figure represents one of the possible displacements of the pattern. That gives us the following true position formula: A simple example would be a set of holes (pattern) used to affix a name plate. These dimensions set up the true position of the bolt holes, and there is no tolerance associated with them. The max material boundary is the. Web an example of this is shown below in figure 1, where we have a drawing of a flanged part with a pattern of bolt holes. It's really another virtual condition, but when it's applied to a datum feature of size all of the cool gd&t geeks call it a max material boundary. Tolerance. That gives us the following true position formula: Web hole / feature pattern plot ; The max material boundary is the. Web the position tolerance is the gd&t symbol and tolerance of location. This can be polar (radius/angle) or cartesian (x,y coordinates) or. In this drawing, the dimensions for the bolt circle diameter and the bolt hole pattern angle are now shown as basic dimensions, highlighted in red in figure 2. This figure represents one of the possible displacements of the pattern. The relative position of the holes is. This is a typical example of what you may find in a number of. The #x designator is used to prevent redundant dimensions when a print has multiple identical features or a pattern. Web hole / feature pattern plot ; Web a datum reference symbol is typically attached to the diameter dimension of the holes in a pattern. Web quickly shows how to use gd&t to locate a simple clearance hole on a flat. Flanged part with a pattern of bolt holes. G&t geometric tolerancing iso 1101 training ; And most likely it does not reflect how the part will be inspected. The holes in the pattern have a feature size tolerance of ±0.1 mm and a position tolerance of 0.5 mm at mmc with respect to datum reference frame abc. This is a. The better datum scheme, the one that reflects how the part functions and how it should be gaged, is shown below. Web hole pattern located by composite tolerancing (primary and secondary datums in lower segment). Web the position tolerance is the gd&t symbol and tolerance of location. The #x designator is used to prevent redundant dimensions when a print has. Web with the dimension scheme completed, add individual geometric tolerances and gd&t symbols. Web true position = 2 x sqrt (xvar^2 + yvar^2) so, we take the difference in x (difference between actual and measured x), square it, add that to the difference in y squared, take the square root of that sum and multiply by 2. By true position,. By true position, we mean the ideal position of the feature according to design. (click on the image to enlarge.) image courtesy of. Web a datum reference symbol is typically attached to the diameter dimension of the holes in a pattern. We are now making this available to eve. You can see on the drawing that the datum feature symbol. A simple example would be a set of holes (pattern) used to affix a name plate. Hole, slot) from its true position. Gd&t geometric dimensioning tolerancing intermediate training ; Web hole pattern located by composite tolerancing (primary and secondary datums in lower segment). The position of the holes with respect to the edges of the plate are of little importance. Web basic dimensions are theoretically exact dimensions. Web in a recent live instruction webinar, we answered four common gd&t questions that we have received from our students. Web the intended interpretation of the gdt in detail c: The max material boundary is the. (click on the image to enlarge.) image courtesy of. Because the oscillating shafts that pass through the bushings do not interface with each other, there is an independent relationship between the (20) individual pairs. The max material boundary is the. Make sure to select ‘bilateral’ or ‘limit’ as tolerance type for features where the plus and minus limit are unequal. Web the intended interpretation of the gdt in detail c: This can be polar (radius/angle) or cartesian (x,y coordinates) or. The true position tolerance in gd&t informs us of the maximum allowable deviation of a feature (e.g. By true position, we mean the ideal position of the feature according to design. The relative position of the holes is. We are now making this available to eve. Web since location if the pattern of holes is not as critical as orientation, the top line of the composite tolerance locates the pattern of holes within 0.4. Web an example of this is shown below in figure 1, where we have a drawing of a flanged part with a pattern of bolt holes. And most likely it does not reflect how the part will be inspected. Web hole pattern located by composite tolerancing (primary and secondary datums in lower segment). It's really another virtual condition, but when it's applied to a datum feature of size all of the cool gd&t geeks call it a max material boundary. Web hole / feature pattern plot ; The position of the holes with respect to the edges of the plate are of little importance to me, say the entire hole pattern could be.

Common GD&T Student Questions A Pattern of Holes as a Datum Feature

Common GD&T Student Questions A Pattern of Holes as a Datum Feature

True Position GD&T Basics

Common GD&T Student Questions A Pattern of Holes as a Datum Feature

Hole Pattern Position With Central Hole as Datum Drafting Standards

Hole Pattern Position With Central Hole as Datum Drafting Standards

GD&T Tip Datums Watch placement of datum triangles in the latest

Composite tolerancing a multifeature hole pattern Drafting Standards

Composite Position Tolerance for Hole pattern. Drafting Standards, GD

Common GD&T Student Questions A Pattern of Holes as a Datum Feature

An Established “True” Central Plane Is Established From The Datum And For The Symmetry To Be In Tolerance, The Median Distance Between Every Point On The Two Surface Features Needs To Fall Near That Central Plane.

Web Quickly Shows How To Use Gd&T To Locate A Simple Clearance Hole On A Flat Plate.instagram:

(Click On The Image To Enlarge.) Image Courtesy Of.

Hole, Slot) From Its True Position.

Related Post: