Gd And T Drawings

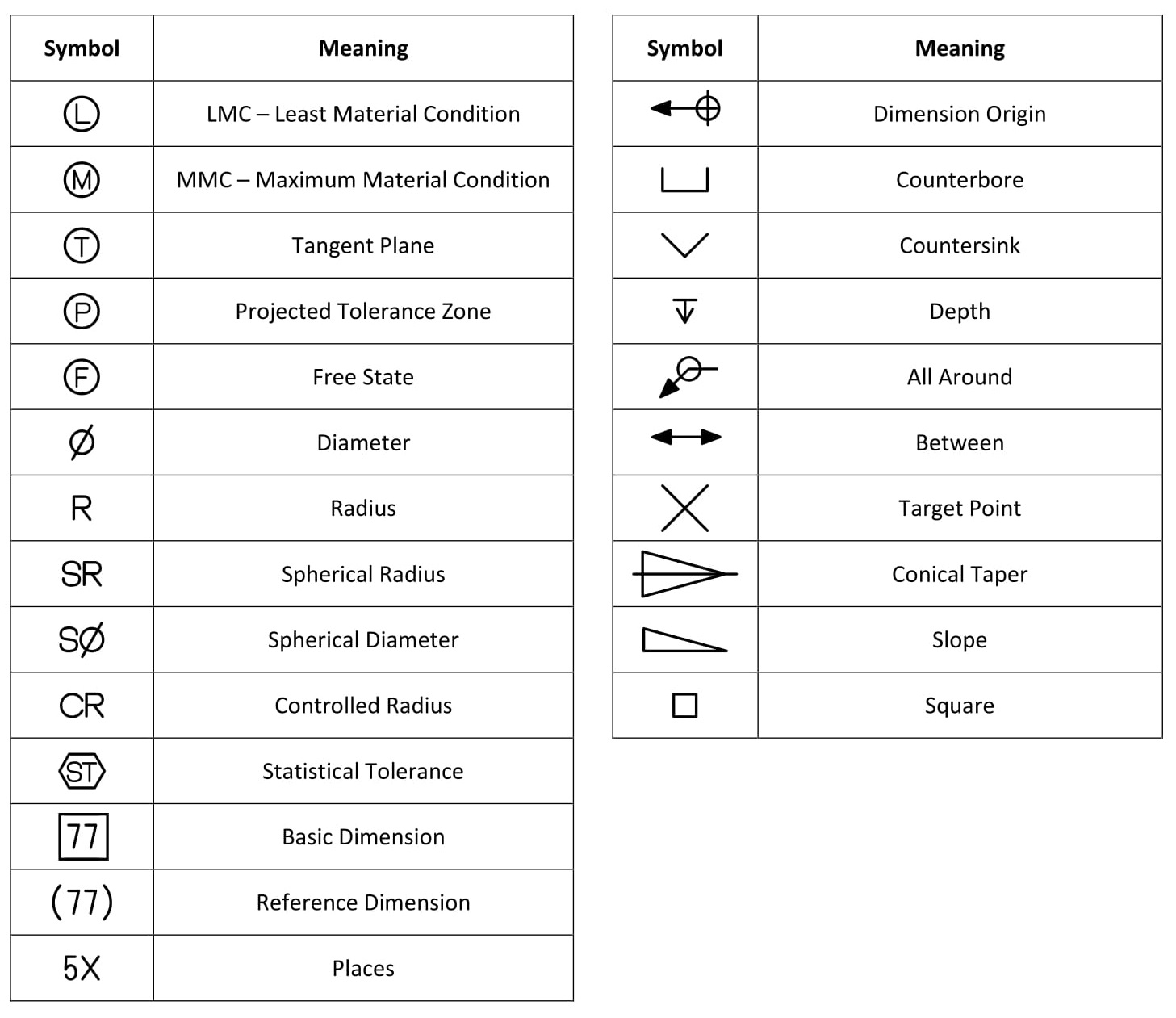

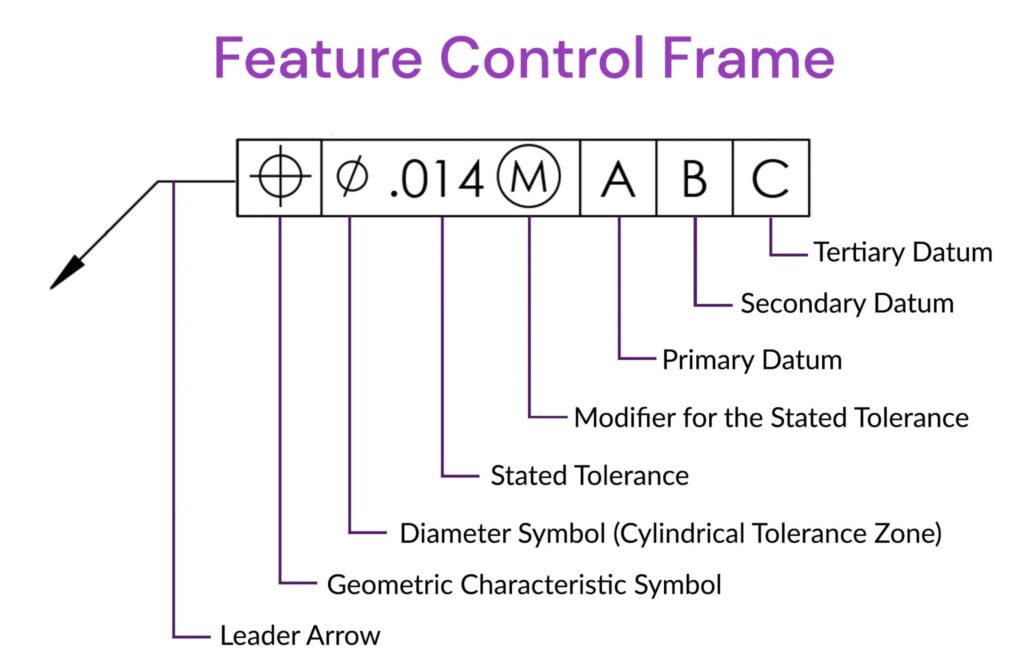

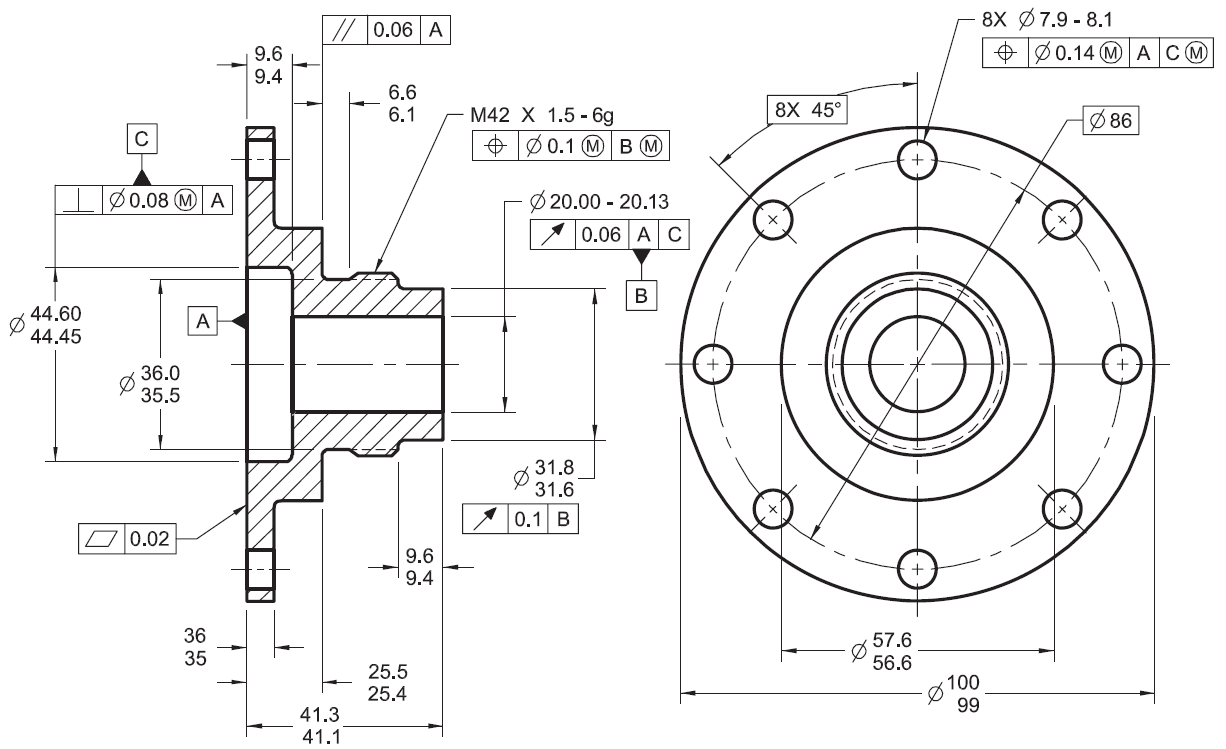

Gd And T Drawings - Web gd&t symbols and definitions help convey the designed object and allow for the manufacturing of mechanical parts in a way that improves quality, lowers manufacturing costs, and shortens delivery time. Web a very common issue that we see on gd&t drawings is the failure to indicate which gd&t standard is being applied. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. Parker’s determination of position (or true position) has since grown to include other concepts including flatness, profile, runout, roundness and much more. Web it establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting gd&t and related requirements for use on engineering drawings, models defined in digital data files, and in related documents. Web gd&t allows for comprehensive and consistent tolerances with the use of relatively simple tools. “learning gd&t from scratch,” provided by keyence, walks you through the basics of geometric dimensioning and tolerancing, datums, and measurements by coordinate measuring. “learning gd&t from scratch,” provided by keyence, walks you through the basics of geometric dimensioning and tolerancing, datums, and measurements by coordinate measuring machines. These are grouped into symbols relating to form, profile, orientation, runout and location. Web gd&t ( geometrical dimensions and tolerances ) is the new vocabulary of engineering drawings. Geometric dimensioning and tolerancing is an international language used in drawings to accurately describe a. Web a very common issue that we see on gd&t drawings is the failure to indicate which gd&t standard is being applied. Web this page explains the 16 symbols used in gd&t, and the classification thereof. Distinguish between a feature and a datum. Common gd&t. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. These are grouped into symbols relating to form, profile, orientation, runout and location. Web a very common issue that we see on gd&t drawings is the failure to. Geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. Distinguish between a feature and a datum. Web a very common issue that we see on gd&t drawings is the failure to indicate which gd&t standard is being applied. A. Web a convenient guide for geometric dimensioning and tolerancing (gd&t) symbols at your fingertips. The concept of gd&t was adopted by the military in the 1950s and is now in use in multiple industries around the world. As with all new systems, there is a learning curve with gd&t. It is an important tool for ensuring the interchangeability, functional accuracy,. Web gd&t ( geometrical dimensions and tolerances ) is the new vocabulary of engineering drawings. In this video, jason highlights the importance of indicating the standard being used and how to. It is an important tool for ensuring the interchangeability, functional accuracy, and reliability of manufactured components. “learning gd&t from scratch,” provided by keyence, walks you through the basics of. By providing uniformity in drawing specifications and interpretation, geometric dimensioning and tolerancing reduces controversy, guesswork, and assumptions throughout the manufacturing and inspection process. Web gd&t ( geometrical dimensions and tolerances ) is the new vocabulary of engineering drawings. These are grouped into symbols relating to form, profile, orientation, runout and location. Gd&t controls variations of size, form, orientation, location and. Web it establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting gd&t and related requirements for use on engineering drawings, models defined in digital data files, and in related documents. Web let's understand the step by step approach to do gd&t for mechanical drawing.understand difference between general dimensioning and tolerancing.understand th. Web gd&t symbols and definitions. Web geometric dimensioning and tolerancing (gd&t) consists of a set of symbols and rules for applying them that communicates the requirements of an engineering blueprint. Web the gd&t methodology was created to standardize the “language” of engineering drawings, so that no matter who you are, or where you were in the world, you could read a drawing and understand exactly. Gd&t controls variations of size, form, orientation, location and runout individually or in combination. This course will teach you the basics of how to understand gd&t symbols and their use. A part drawing may include a single gd&t callout, or the drawing may be fully defined using gd&t depending on part requirements. Web a very common issue that we see. Web the gd&t methodology was created to standardize the “language” of engineering drawings, so that no matter who you are, or where you were in the world, you could read a drawing and understand exactly what is required for that component. Web this page shows a list of gd&t symbols and associated symbols used by iso and asme. In this. Web what is gd&t? “learning gd&t from scratch,” provided by keyence, walks you through the basics of geometric dimensioning and tolerancing, datums, and measurements by coordinate measuring machines. Web gd&t ( geometrical dimensions and tolerances ) is the new vocabulary of engineering drawings. This course will teach you the basics of how to understand gd&t symbols and their use. What is geometric dimensioning & tolerancing (gd&t) By providing uniformity in drawing specifications and interpretation, geometric dimensioning and tolerancing reduces controversy, guesswork, and assumptions throughout the manufacturing and inspection process. Web geometric dimensioning and tolerancing (gd&t) consists of a set of symbols and rules for applying them that communicates the requirements of an engineering blueprint. Web gd&t allows for comprehensive and consistent tolerances with the use of relatively simple tools. Web gd&t is an international language used on engineering drawings. If you are involved in design or manufacturing, you may be familiar with the term, “gd&t,” or “geometric dimensioning and tolerancing”. Web this page explains the 16 symbols used in gd&t, and the classification thereof. Describe the scope of gd&t standards. This is the language that your drawings speak. Web a very common issue that we see on gd&t drawings is the failure to indicate which gd&t standard is being applied. The concept of gd&t was adopted by the military in the 1950s and is now in use in multiple industries around the world. Common gd&t symbols are listed in the table below.

GD&T The Beginner's Guide to Geometric Dimensioning and Tolerancing

Design Tech Academy (1)Geometric Dimensioning and Tolerancing (GD&T

What are Geometric dimensioning and tolerancing GD & T Symbols

GD&T 101 An Introduction to Geometric Dimensioning and Tolerancing

Examples on how to interpret GD&T Form, orientation, location and run

GD&T Tips Profile As a General Tolerance

GD&T Drawings KOHLEX

Engineering Drawings & GD&T For the Quality Engineer Mechanical

GD&T Basics What You Need to Know

GD&T for beginners step by step approach to do gd&t for mechanical

Web This Videos Covers The Different Geometric Characteristics And Other Key Aspects Of Gd&T Including Datums, Material Modifiers (Mmc, Lmc And Rfs), The Envelope Principle (Also Called Gd&T Rule #1.

Web The Gd&T Methodology Was Created To Standardize The “Language” Of Engineering Drawings, So That No Matter Who You Are, Or Where You Were In The World, You Could Read A Drawing And Understand Exactly What Is Required For That Component.

Web Gd&T Symbols And Definitions Help Convey The Designed Object And Allow For The Manufacturing Of Mechanical Parts In A Way That Improves Quality, Lowers Manufacturing Costs, And Shortens Delivery Time.

As With All New Systems, There Is A Learning Curve With Gd&T.

Related Post: