Foundry Pattern Making

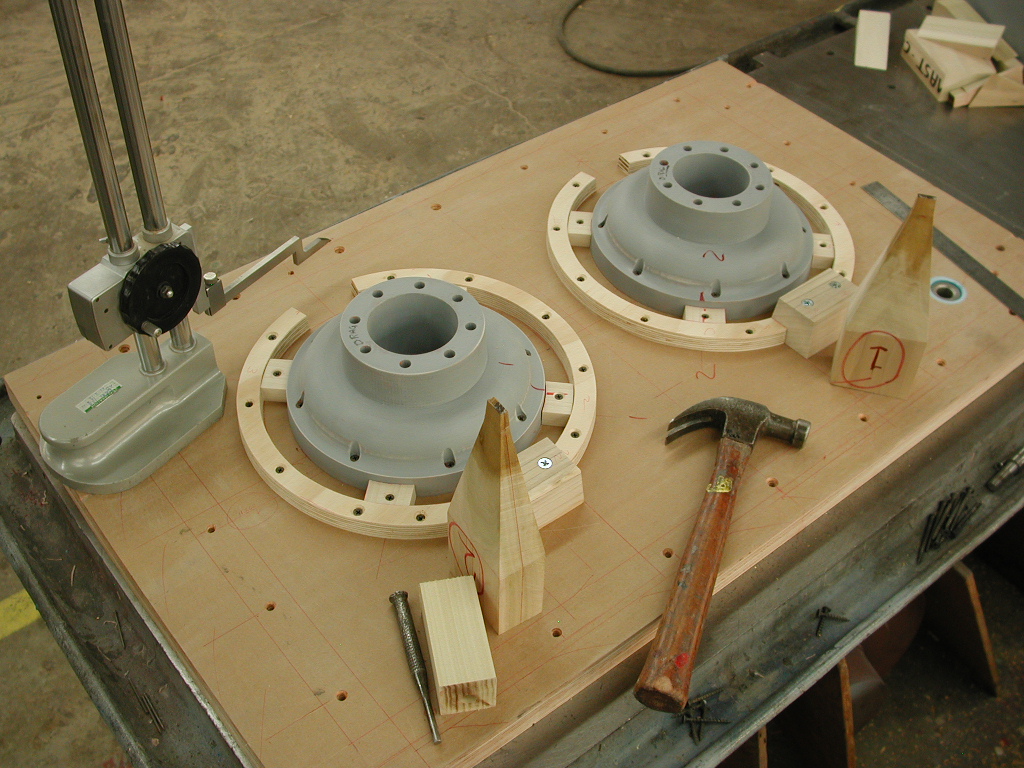

Foundry Pattern Making - Web foundry patterns for gears were first made of wood and then cast into metal. There are different types of patterns, but they fall into two major subtypes: Our use of polystyrene patterns for that “breakdown” one piece casting process, has many times put a customer back in operation in less than 2 weeks. Web discover the old world metal foundry craft. We have a very skilled group of designers and patternmakers using the best equipment and methods to capture the complexity. Every pattern includes a gating system that delivers liquid metal to the mold cavity. Cores to accommodate holes can be seen in the bottom half of the mould, which is called the drag. We work hard to find the balance between the different types of tooling based on the number of castings needed, total project duration, and casting. However, casting remains unparalleled in producing complex, large parts with minimal wastage. Yuval atsmon is a senior partner who leads the new mckinsey center for strategy innovation, which studies ways new technologies can augment the timeless principles of strategy. We have a very skilled group of designers and patternmakers using the best equipment and methods to capture the complexity. The gating system also regulates the speed that the metal enters the mold—too fast, and the turbulent liquid. Reusable ones for sand or plaster casting, which make. Foundry pattern making involves producing the model that allows the mold for metal. In metal casting, patterns are the objects used to create expendable molds. The art and science of preparing the pattern is called pattern making. This book provides a good overview to pattern making within the context of the foundry. The pattern is used to create the mold cavity into which molten material will be poured to solidify and form the.. We work hard to find the balance between the different types of tooling based on the number of castings needed, total project duration, and casting. Patterns are produced in wood, plastic or polystyrene. Precision cnc wood and urethane pattern construction. Web this will be a multi part video on foundry pattern making. Draft, fillets and radii (each depicted in fig. In casting, a pattern is a replica of the object to be cast, used to form the sand mould. Usually made out of wood, metal or model board, patterns are used to create cavities in moulds. Foundry pattern making involves producing the model that allows the mold for metal casting to be manufactured in the foundry. Foundry pattern making is. We work hard to find the balance between the different types of tooling based on the number of castings needed, total project duration, and casting. Announced another leadership change for the chipmaker’s contract manufacturing efforts, making marvell technology inc. Web helldivers 2 fans are making cape designs out of steam reviews, and they might appear in the game the accidental. Draft, fillets and radii (each depicted in fig. Your foundry patterns, master patterns, and match plates will be designed and manufactured by experts. Web foundry patterns for gears were first made of wood and then cast into metal. 2.2.1 pattern materials some of the common materials used for pattern making are wood, metal, plaster, wax and plastic. Pattern construction can. All patterns need a gating system. Web pact casting quality, none can make up for a poor pattern design. Announced another leadership change for the chipmaker’s contract manufacturing efforts, making marvell technology inc. Web and of course, for low volume parts, the 3d printing process is ideal. A wooden pattern is used to make an impression in the sand mold. Cpm designs and builds pattern equipment to meet the needs of the casting as well as the foundry. Key steps in the steel foundry process a. In metal casting, patterns are the objects used to create expendable molds. This book provides a good overview to pattern making within the context of the foundry. Foundry pattern making is a field of. The top half of the mould is called the cope. 2.2.1 pattern materials some of the common materials used for pattern making are wood, metal, plaster, wax and plastic. Announced another leadership change for the chipmaker’s contract manufacturing efforts, making marvell technology inc. We work hard to find the balance between the different types of tooling based on the number. When the water cools at least 0.9 degree fahrenheit below average for three. Announced another leadership change for the chipmaker’s contract manufacturing efforts, making marvell technology inc. While casting is integral to steel production, it is not the sole method. Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. Executive. O’buckley was named senior vice president and general manager of foundry services, the unit tasked with manufacturing chips for. Web the foundry patternmaking nc ii is one of the most essential competencies offered by tesda, designed to equip individuals with the skills and techniques required to manufacture all types of patterns and pattern component parts, from general engineering patterns to complex master patterns with multiple contraction.through the program, students learn. In metal casting, patterns are the objects used to create expendable molds. Draft, fillets and radii (each depicted in fig. All patterns need a gating system. Web foundry patterns for gears were first made of wood and then cast into metal. Many factors have to be taken into consideration when. Key steps in the steel foundry process a. In casting, a pattern is a replica of the object to be cast, used to form the sand mould. Executive kevin o’buckley head of its foundry division. At arnette, we specialize in providing high quality, precision, wood, plastic, and metal foundry patterns for the metal casting industry. The pattern is used to create the mold cavity into which molten material will be poured to solidify and form the. Web this will be a multi part video on foundry pattern making. Patterns are produced in wood, plastic or polystyrene. Executive kevin o’buckley head of its foundry division. It is the first step in the ductile iron casting process.

Sand Casting Pattern Design Foundry Pattern Shop Badger Alloys

Patternmaking and Casting Pattern Making Patternmaking Castings

Learn about patterns definition, classification and how to make pattern

Foundry Pattern Making Life of a Casting Reliance Foundry

Pattern Shop South Lincs Foundry

Foundry Pattern Service Experienced patternmakers equipped to handle

Foundry Pattern Making Life of a Casting Reliance Foundry

Foundry Pattern Making Life of a Casting Reliance Foundry

Pattern Making for the Foundry The Basics you NEED to Know! YouTube

Foundry Pattern Making Life of a Casting Reliance Foundry

Usually Made Out Of Wood, Metal Or Model Board, Patterns Are Used To Create Cavities In Moulds.

Cpm Designs And Builds Pattern Equipment To Meet The Needs Of The Casting As Well As The Foundry.

The Gating System Also Regulates The Speed That The Metal Enters The Mold—Too Fast, And The Turbulent Liquid.

Web What Is Foundry Pattern Making?

Related Post: