Fat Test Template

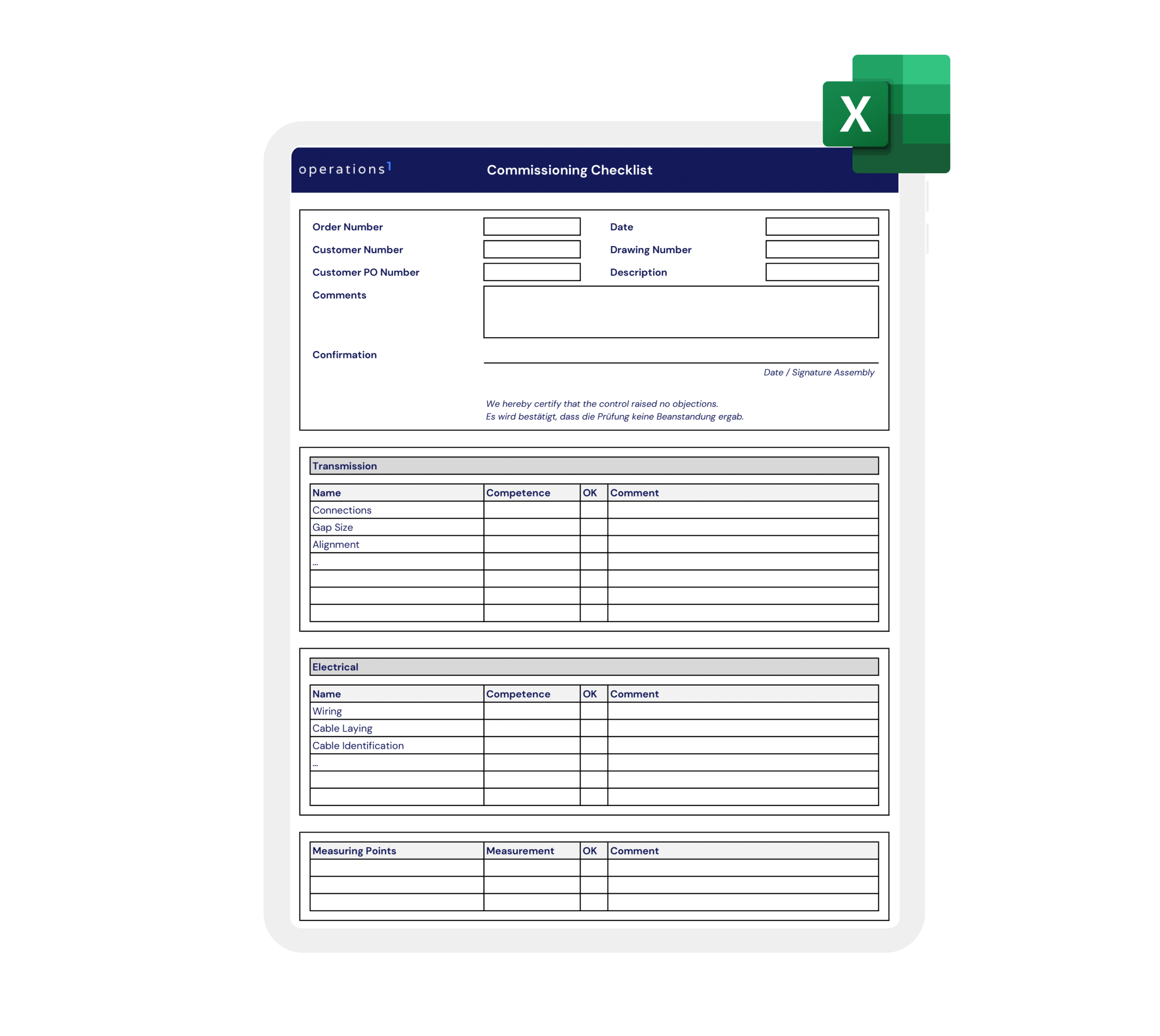

Fat Test Template - Web the factory acceptance test (fat) refers to the functional test that is performed by the vendor upon completion of the manufacturing process to prove the equipment has the. This is often the level of acceptance test for equipment that is similar to other. Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. Web steps to write a factory acceptance test fat protocol for the equipment purchased for pharmaceutical manufacturing. Why is a factory acceptance test checklist? Web the checklist tool for factory acceptance tests assists you in setting clear expectations for machine functionality and allows you to validate these were met prior to shipment from. In the world of industrial automation, a factory acceptance test or fat is simply a test for a newly manufactured control. Web factory acceptance testing (fat) is a process within the manufacturing and quality assurance phase of industrial equipment or systems. Web use this factory acceptance test (fat) checklist to document the complete/incomplete fat protocol, capture photo evidence of the entire fat procedure, including hazard. A good factory acceptance test checklist should enable quality managers to verify the following and more: This article deals with the following topics: Web the template applies mainly to system testing for hydropower plants, but can easily be modified for other plant types, since the system parts and functions. Web the checklist tool for factory acceptance tests assists you in setting clear expectations for machine functionality and allows you to validate these were met prior to. Before a bpcs/sis is shipped from its staging site to the final plant site, a factory acceptance test (fat) may. It ensures the equipment does. Contact us to get ms word document without the footer. So the plc panel will be tested at the factory and only accepted by the client if it is functioning properly as per the design.. Web template document prepared by sensum. So the plc panel will be tested at the factory and only accepted by the client if it is functioning properly as per the design. Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. Safety devices test # test. Why is a. Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. Web template document prepared by sensum. This is often the level of acceptance test for equipment that is similar to other. This article deals with the following topics: Web factory acceptance testing (fat) is a process within the manufacturing. Sample protocol template is also. Web the factory acceptance test (fat) refers to the functional test that is performed by the vendor upon completion of the manufacturing process to prove the equipment has the. Web factory acceptance testing (fat) is a process within the manufacturing and quality assurance phase of industrial equipment or systems. Web this process is called fat. This article deals with the following topics: Web the factory acceptance test (fat) refers to the functional test that is performed by the vendor upon completion of the manufacturing process to prove the equipment has the. Web factory acceptance testing (fat) is a process within the manufacturing and quality assurance phase of industrial equipment or systems. Web factory acceptance testing. Web template document prepared by sensum. This article deals with the following topics: Sample protocol template is also. The purpose of the fat is to identify any. Web factory acceptance testing (fat) is a test performed for newly manufactured and packaged equipment by the vendor prior to shipping to ensure the equipment meets its. This is often the level of acceptance test for equipment that is similar to other. Web template document prepared by sensum. Web factory acceptance tests (fats) are performed to verify that the equipment’s specification suits a buyer's requirements. Web a factory acceptance test (fat) is a series of tests and inspections that are completed by an equipment supplier. The purpose. Pdf template, use this factory acceptance test (fat) checklist to document the complete::incomplete fat. Before a bpcs/sis is shipped from its staging site to the final plant site, a factory acceptance test (fat) may. Web template document prepared by sensum. It ensures the equipment does. This article deals with the following topics: This article deals with the following topics: A good factory acceptance test checklist should enable quality managers to verify the following and more: Rigorous safety tests during the fat ensure the equipment adheres to all relevant safety regulations and standards,. The purpose of the fat is to identify any. Web the template applies mainly to system testing for hydropower plants,. Web a factory acceptance test (fat) is a series of tests and inspections that are completed by an equipment supplier. Web factory acceptance testing (fat) is a test performed for newly manufactured and packaged equipment by the vendor prior to shipping to ensure the equipment meets its. Safety devices test # test. Before a bpcs/sis is shipped from its staging site to the final plant site, a factory acceptance test (fat) may. Web the factory acceptance test (fat) refers to the functional test that is performed by the vendor upon completion of the manufacturing process to prove the equipment has the. Sample protocol template is also. Why is a factory acceptance test checklist? Web enhanced safety and quality: Web this process is called fat (factory acceptance test). Web a factory acceptance test template is an essential tool for ensuring successful factory acceptance testing (fat) of equipment and machinery. This is often the level of acceptance test for equipment that is similar to other. Rigorous safety tests during the fat ensure the equipment adheres to all relevant safety regulations and standards,. Overall check of installation & connections of all cabling (separate fat already done in factory of panel builder) check good functioning of all mdbs. Web use this factory acceptance test (fat) checklist to document the complete/incomplete fat protocol, capture photo evidence of the entire fat procedure, including hazard. It ensures the equipment does. The purpose of the fat is to identify any.

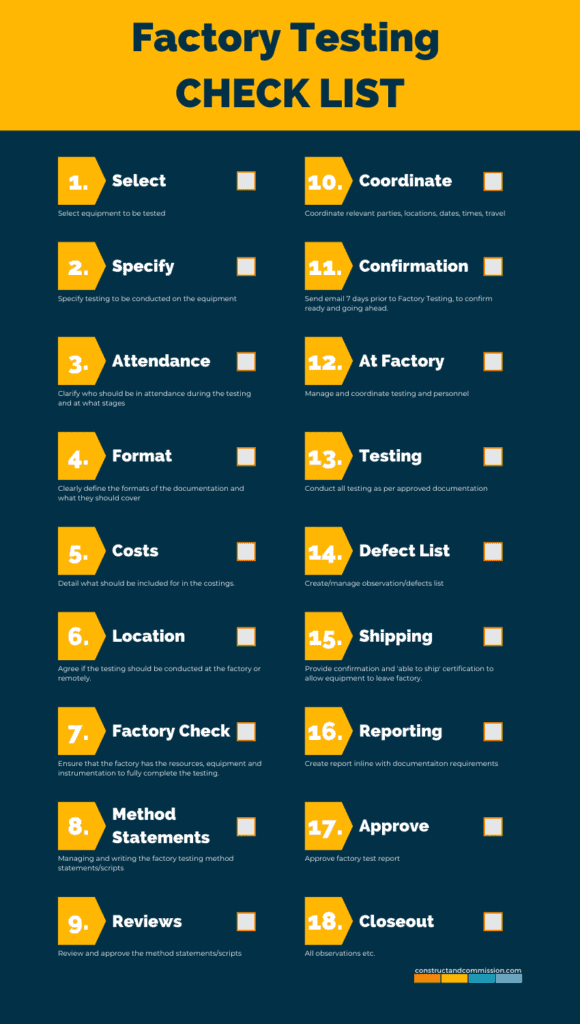

Free Factory Acceptance Testing checklist (FAT) Better than PPT & PDF

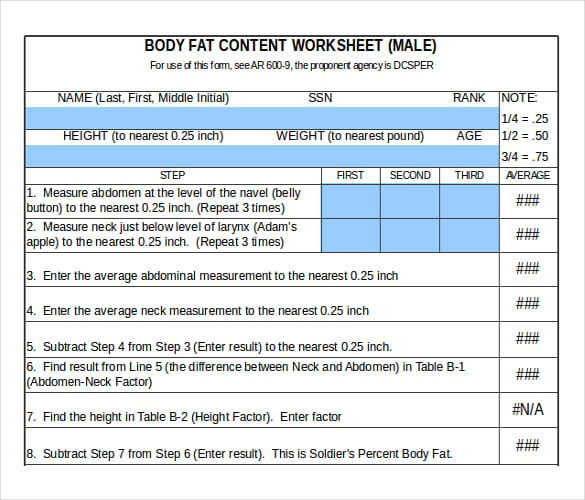

FREE 7+ Sample Body Fat Percentage Chart Templates in PDF MS Word

FAT PROCEDURE & TEST PLAN.pptx

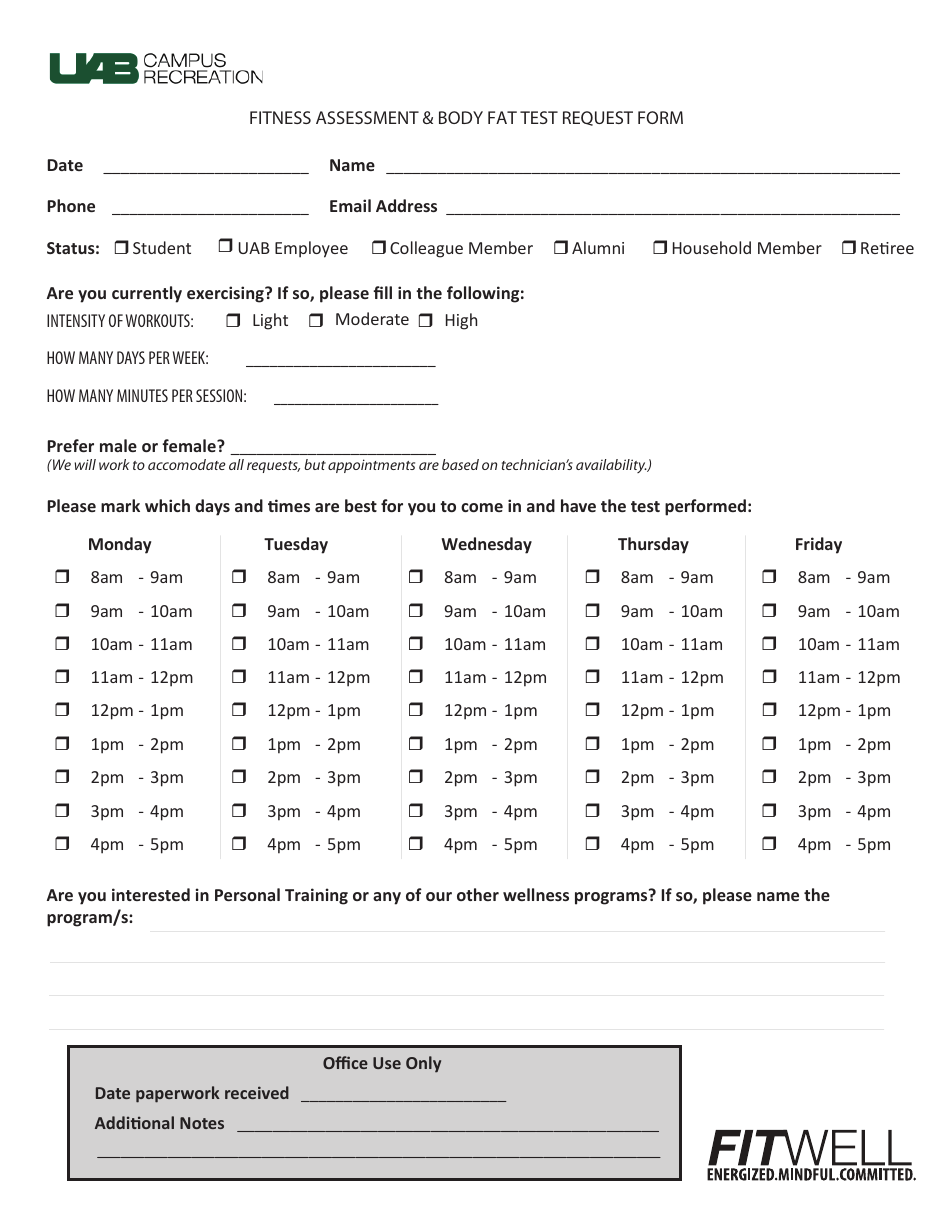

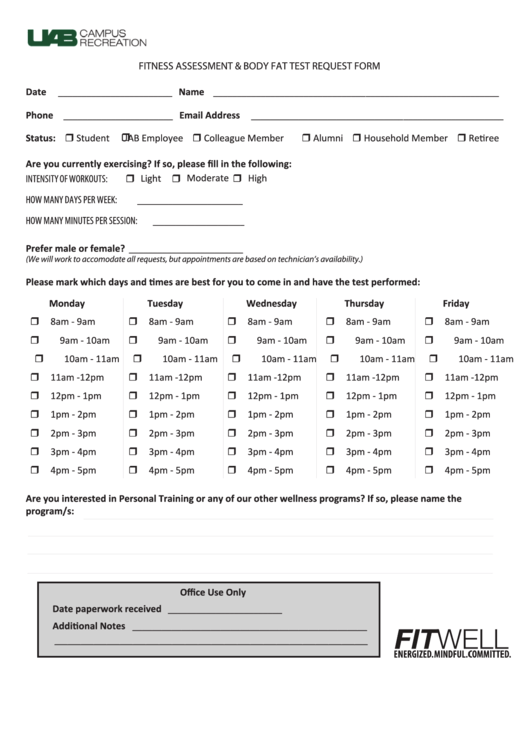

Fitness Assessment & Body Fat Test Request Form Campus Recreation

Fillable Online 100 Gram Fat Test Diet Fax Email Print pdfFiller

Free Factory Acceptance Testing checklist (FAT) Better than PPT & PDF

FACTORY ACCEPTANCE TESTING Guideline, Agenda & Report

FAT Protocol Template Free Download

Fitness Assessment & Body Fat Test Request Form printable pdf download

Body Fat Chart Templates 6+ Free Excel, PDF Documents Download Free

Contact Us To Get Ms Word Document Without The Footer.

Pdf Template, Use This Factory Acceptance Test (Fat) Checklist To Document The Complete::incomplete Fat.

Web The Checklist Tool For Factory Acceptance Tests Assists You In Setting Clear Expectations For Machine Functionality And Allows You To Validate These Were Met Prior To Shipment From.

Progress Of A Factory Acceptance Test.

Related Post: