Double Lvl Nailing Pattern

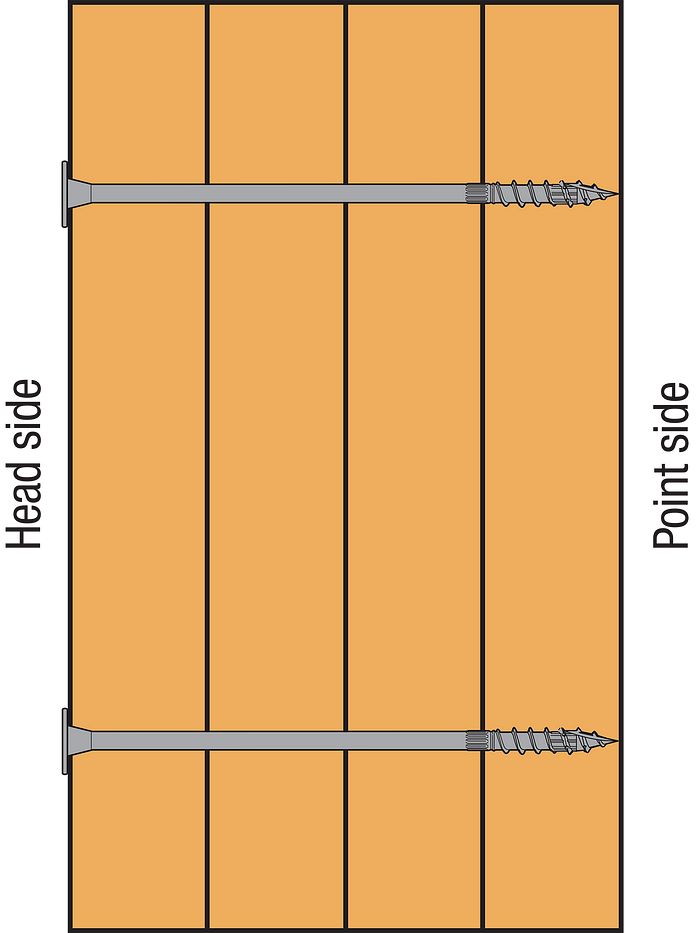

Double Lvl Nailing Pattern - Web nailing parallel to glue lines (narrow face) 1) for 1¾ thickness and greater, 2 rows of nails (such as for a metal strap) are allowed (use ½ minimum offset between rows and stagger nails). Test results for lvl block shear and tensile strengths are summarized in table 2. Ideally i would be using minimal acceptable # of fasteners for reasons i. Nail spacing, nail pattern, how many and how to join & fix bowed beams. Web #1 · jul 6, 2017. A good example of a nailing pattern on a double lvl. Microllam® lvl beams work well in applications all over the house. While still on the ground, we cut the main beam’s. Minimum nail spacing may be reduced to 5. This pattern is maintains a 3” on center. A good example of a nailing pattern on a double lvl. Microllam® lvl beams work well in applications all over the house. This pattern is maintains a 3” on center. Web the most common way to build them is simply nailing them together. I use construction adhesive between each lvl. Web minimum nail spacing for nails installed parallel to the glueline 1. There are different standards for the specifics of nailing them up. While still on the ground, we cut the main beam’s. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern. The following is an allowable load chart for determining the proper. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that. Web 4.1 lvl block shear and tensile strengths. Minimum nail spacing may be reduced to 5. Web the. Test results for lvl block shear and tensile strengths are summarized in table 2. There are different standards for the specifics of nailing them up. Web the most common way to build them is simply nailing them together. Web for beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under. Web 4.1 lvl block shear and tensile strengths. Web the most common way to build them is simply nailing them together. Web nail size nailed bolted 2 rows 16d common at 12” o.c. We are building a screen porch for a client that has been designed by the architect with a double lvl ridge beam for the purpose of having. While still on the ground, we cut the main beam’s. The average moisture content and specific gravity. Minimum nail spacing may be reduced to 5. 2 rows 1/2” bolts at 24” o.c. I use construction adhesive between each lvl. The average moisture content and specific gravity. What is the best technique for. Web #1 · jul 6, 2017. Web we nailed off the beam with 16d nails in a robust nailing pattern, keeping the pair aligned by toenailing as needed. Web the most common way to build them is simply nailing them together. 3 rows 1/2” bolts at 12” o.c. Minimum nail spacing may be reduced to 5. Test results for lvl block shear and tensile strengths are summarized in table 2. While still on the ground, we cut the main beam’s. 4.1k views 2 years ago building: Microllam® lvl beams work well in applications all over the house. 4.1k views 2 years ago building: 3 rows 1/2” bolts at 12” o.c. Minimum nail spacing may be reduced to 5. There are different standards for the specifics of nailing them up. Web nail size nailed bolted 2 rows 16d common at 12” o.c. Web #1 · jul 6, 2017. This pattern is maintains a 3” on center. Web for those who are uninitiated in the world of fasteners, a nailing pattern or fastener schedule is the national, state or regional building code allowances for fastening. We are building a screen porch. 3 rows 16d common at 12” o.c. While still on the ground, we cut the main beam’s. Web design information for timberstrand lsl, microllam lvl and parallam psl. I use construction adhesive between each lvl. Nailing perpendicular to glue lines (wide face) closest. Web 4.1 lvl block shear and tensile strengths. Microllam® lvl beams work well in applications all over the house. Web the recommended nailing pattern for fastening lvl beams together is to use pairs of 16d nails every 12 inches along the beam. The following is an allowable load chart for determining the proper. Test results for lvl block shear and tensile strengths are summarized in table 2. 4.1k views 2 years ago building: 2 rows 1/2” bolts at 12” o.c. Web for those who are uninitiated in the world of fasteners, a nailing pattern or fastener schedule is the national, state or regional building code allowances for fastening. This pattern is maintains a 3” on center. A good example of a nailing pattern on a double lvl. Web we nailed off the beam with 16d nails in a robust nailing pattern, keeping the pair aligned by toenailing as needed.

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

/LaminatedBeamLVL-103307652-56e1ad553df78c5ba0569d46.jpg)

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

Nailing Pattern For Lvl Beam Nail Ftempo

2 Rows 1/2” Bolts At 24” O.c.

Web #1 · Jul 6, 2017.

The Top Row Of Nails Should Be.

What Is The Best Technique For.

Related Post: