Differential Gear Patterns

Differential Gear Patterns - Web five cut ring & pinion gears (face milled): Web our differential installation and setup guide comes with each sierra gear & axle master differential installation kit. In this video we give a quick demonstration of how to apply. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Every gear has a characteristic pattern. The top land of a gear tooth is the surface of the top of the tooth. Use shims to move the ring gear closer to the pinion to decrease backlash. Low contact pattern is concentrated in the root of the drive gear tooth. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the toe. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Begin by setting proper pinion bearing preload, total turning preload,. Pulling off a proper differential setup comes down to. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web here's how to achieve the best ring & pinion contact pattern , every time, in just. Web five cut ring & pinion gears (face milled): ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. The order in which adjustments are made during differential assembly and setup are: Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Web the pattern refers. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. If you're installing gears, we recommend reading through all of the below links (okay, maybe not #4). Web our differential installation and setup guide comes with each sierra gear & axle master differential installation kit. The coast pattern will move deeper toward the tooth flank. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. The order in which adjustments are made during differential assembly and setup are: Use shims to move the ring gear closer to the pinion to decrease. Tooth contact patterns are a function of the relative positions of the ring gear and the pinion. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web how to read a differential gear pattern: Web the heel of the gear tooth is the portion of the tooth. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. If you're installing gears, we recommend reading through all of the below links (okay, maybe. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. The top land of a gear tooth. Web high contact pattern is concentrated at the crown of the drive gear tooth. Web after differential preload and gear backlash adjustments are complete, check the tooth contact pattern and adjust if necessary. Pattern adjustment cause & effect. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long. Tooth contact patterns are a function of the relative positions of the ring gear and the pinion. Web high contact pattern is concentrated at the crown of the drive gear tooth. Use shims to move the ring gear closer to the pinion to decrease backlash. One is manufactured by face hobbing, while the other one is manufactured by face milling.. You'll get some different points of view on. Web after differential preload and gear backlash adjustments are complete, check the tooth contact pattern and adjust if necessary. Web in general, pattern movements can be summarized this way: Web this is a demonstration of the proper setup of a ring and pinion gear set in the rear. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. Tooth contact patterns are a function of the relative positions of the ring gear and the pinion. Use shims to move the ring gear closer to the pinion to decrease backlash. Low contact pattern is concentrated in the root of the drive gear tooth. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web there are two types of gears which are determined by the machining method. Begin by setting proper pinion bearing preload, total turning preload, and ring gear backlash. This video was created to give people a basic understanding of how to read gear patterns when. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. See how to set up a ring and pinion gear set. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Pattern adjustment cause & effect.

How to Set up Your Rear Gear Correctly RacingJunk News

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

How to Set up Your Rear Gear Correctly RacingJunk News

How To Create & Read Ring Gear Patterns

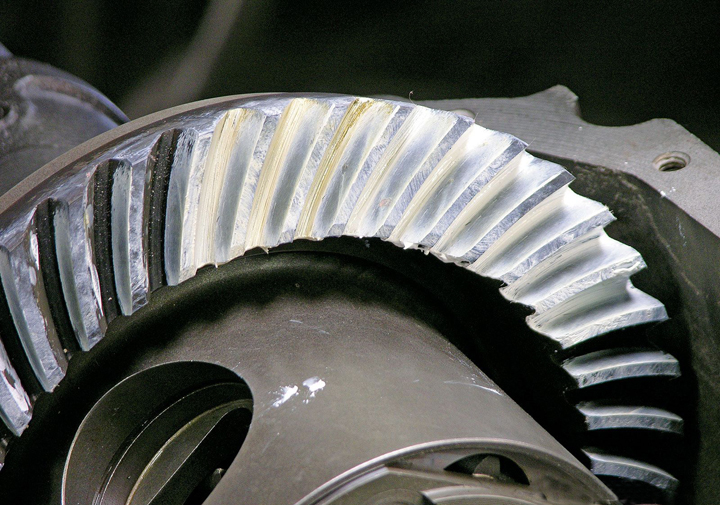

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Differential Installation Instructions West Coast Differentials

Differential Unitec automotive engineering study 2012

Fig. 1 Drive Axle Gear Tooth Pattern s

Once backlash is within spec you can set the pinion depth by reading

Web The Heel Of The Gear Tooth Is The Portion Of The Tooth Surface At The Outer End.

The Order In Which Adjustments Are Made During Differential Assembly And Setup Are:

Pulling Off A Proper Differential Setup Comes Down To.

One Is Manufactured By Face Hobbing, While The Other One Is Manufactured By Face Milling.

Related Post: