Casting Pattern

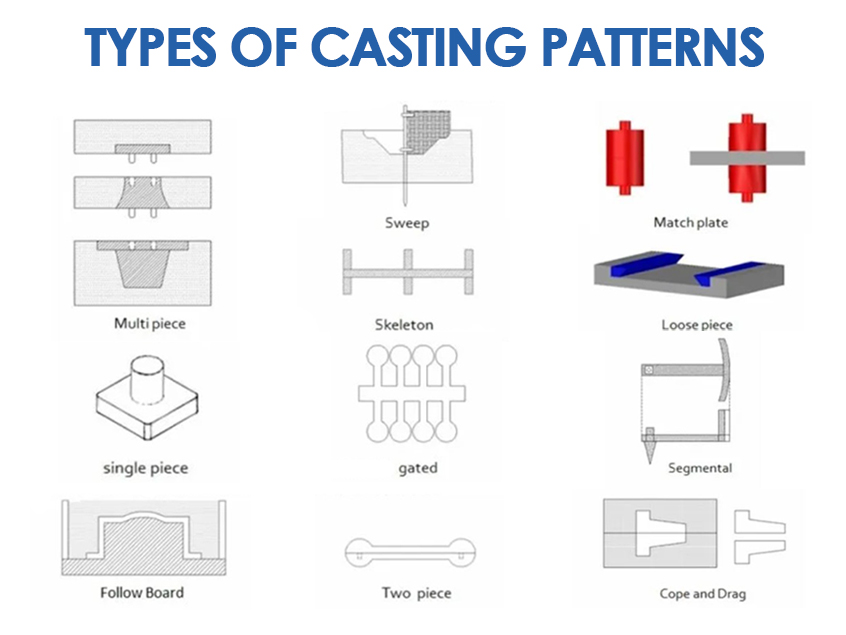

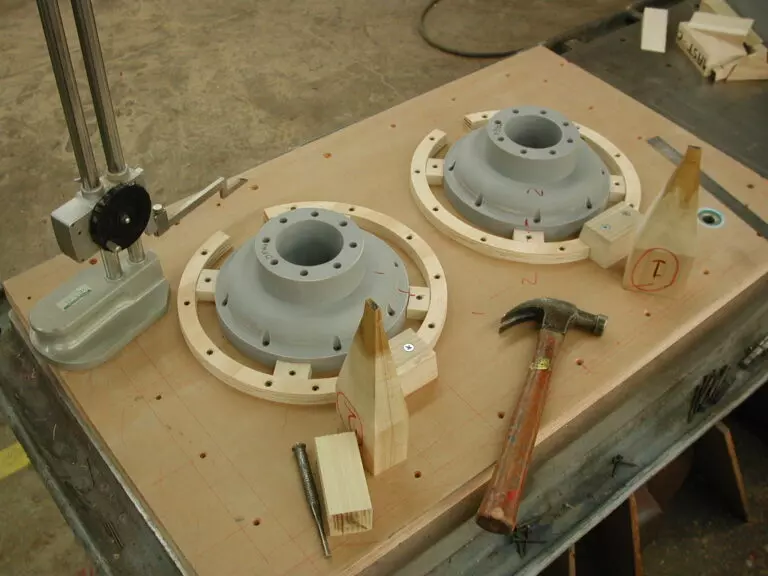

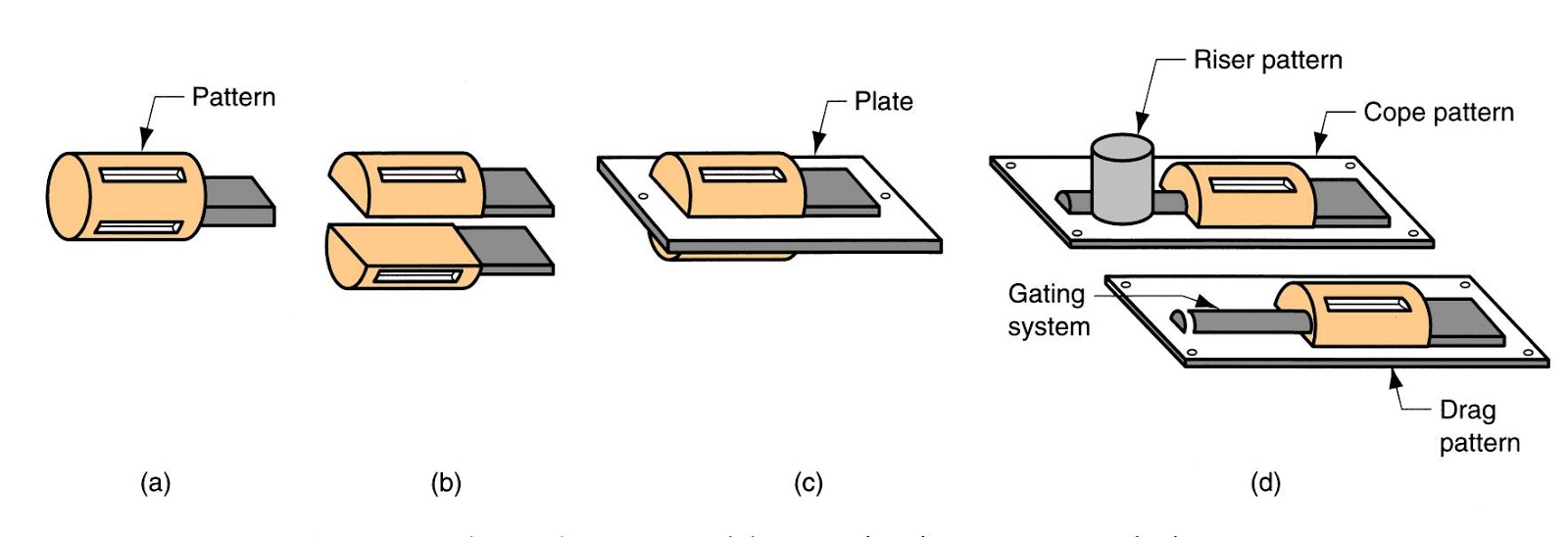

Casting Pattern - Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. 12 types of patterns in casting process read. This article discusses the types of patterns used for a specific application such as loose patterns, match plate patterns, cope and drag patterns, and special patterns. Web foundry pattern service has the ability and experience to meet your unique pattern needs. Durable material provides a long lifetime for your casting pattern. By using cope and drag pattern, two parts of mold can be produced separately, and later it can. It is defined as a model of anything constructed in such a way that it may be used for forming an impression called “mould” in damp sand or other suitable material. Split patterns are employed for creating more complex shapes and larger production quantities. It's the science of making an original pattern or form which will be used to make a mold. Web a pattern is a replica of the part to be produced by casting. It is defined as a model of anything constructed in such a way that it may be used for forming an impression called “mould” in damp sand or other suitable material. From this mold, a pattern is cast from a material that can melt or. Web pattern (casting) the top and bottom halves of a sand casting mould showing the. Web a pattern (or tool) is designed to optimize the castability of a part and provide a casting that is dimensionally accurate. Web investment casting patterns are typically made out of wax or 3d printed polymers. The top half of the mould is called the cope. In casting, a pattern is a replica of the object to be cast, used. Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. A split pattern is a type of pattern used in the casting process. Every good ductile iron casting is the result of a good pattern. From this mold, a pattern is cast from a material that can melt or. Durable material provides a. A split pattern is a type of pattern used in the casting process. During the process of solidification, a mold must have been designed to suitably place the appropriate sized risers to supply the molten metal into casting. The casting process can produce everything from art pieces to engine parts. From this mold, a pattern is cast from a material. A pattern can be both simple and complex for e.g an object that has detail on. It describes the principles of the patternmaking techniques used to make expendable molds and for metal casting processes such as die casting and permanent mold casting. In addition to split pattern, it has a gating and riser system attached separately to the face plates.. Web the main function of a casting pattern is to mold a cavity in the molding sand mixture such that the formed cavity looks the same as the casting product. They are physical replicas or models used to create the mold. 12 types of patterns in casting process read. Patterns are a model for the object to be cast. During. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand is the material the mold is to be made from. Web casting patterns are the most crucial component in the metal casting process. One of the oldest living proofs of complex pattern in which a frog cast in copper. So the pattern is very critical to the final part. Web investment casting patterns are typically made out of wax or 3d printed polymers. Various industries need casting patterns for the casting process, so the versatile property of casting pattern material is very important. Patterns are produced in wood, plastic or polystyrene, depending upon customer needs. Casting patterns for complicated. Cope and drag pattern these are similar to the split piece pattern. It is defined as a model of anything constructed in such a way that it may be used for forming an impression called “mould” in damp sand or other suitable material. Cores to accommodate holes can be seen in the bottom half of the mould, which is called. The shape is determined by the mold cavity, but something needs to shape the mold—that’s where the pattern comes in. Split patterns are employed for creating more complex shapes and larger production quantities. The mold will allow for mass production of the original pattern by poring some sort of casting material such as metal, resin, plaster, or other material. Web. Web types of patterns in casting. During the process of solidification, a mold must have been designed to suitably place the appropriate sized risers to supply the molten metal into casting. The shape is determined by the mold cavity, but something needs to shape the mold—that’s where the pattern comes in. From this mold, a pattern is cast from a material that can melt or. A replica pattern is used to create a mold out of rubber, metal, or resin. One of the oldest living proofs of complex pattern in which a frog cast in copper has been found. Web patten is the tool used during the casting process. They are physical replicas or models used to create the mold. A pattern can be both simple and complex for e.g an object that has detail on. As we discussed, casting objects are highly dependent on the pattern. Web history of casting patterns. The casting process can produce everything from art pieces to engine parts. Patterns are produced in wood, plastic or polystyrene, depending upon customer needs. According to the shape and size of casting and method of making cavity, the pattern can be classified as follow: There are different types of patterns in casting. Our use of polystyrene patterns for that “breakdown” one piece casting process, has many times put a customer back in operation in less than 2 weeks.

Patterns Clinch River Casting Iron Casting Foundry TN

11 Most Common Types of Patterns Used in Casting G For Games

An Introduction to Metal Casting Process Stanford Advanced Materials

10 Different Typess of Pattern in Casting Engineering Choice

Foundry Pattern Making Life of a Casting Reliance Foundry

Types of patterns used in Casting Process Mechanical Engineering

11 Most Common Types of Patterns Used in Casting G For Games

Casting Patterns and Patternmaking Metal Casting Blog

Types of Patterns in Casting Process Mechanical Booster

Types of patterns used in Casting Process Mechanical Engineering

So The Pattern Is Very Critical To The Final Part.

Web What Is The Types Of Patterns In Casting? According To Wikipedia’s Explanation, A Pattern Is A Copy Of The Object To Be Cast.

Casting Patterns For Complicated Casting.

Web Investment Casting Patterns Are Typically Made Out Of Wax Or 3D Printed Polymers.

Related Post: