Beginner Mig Welding Patterns

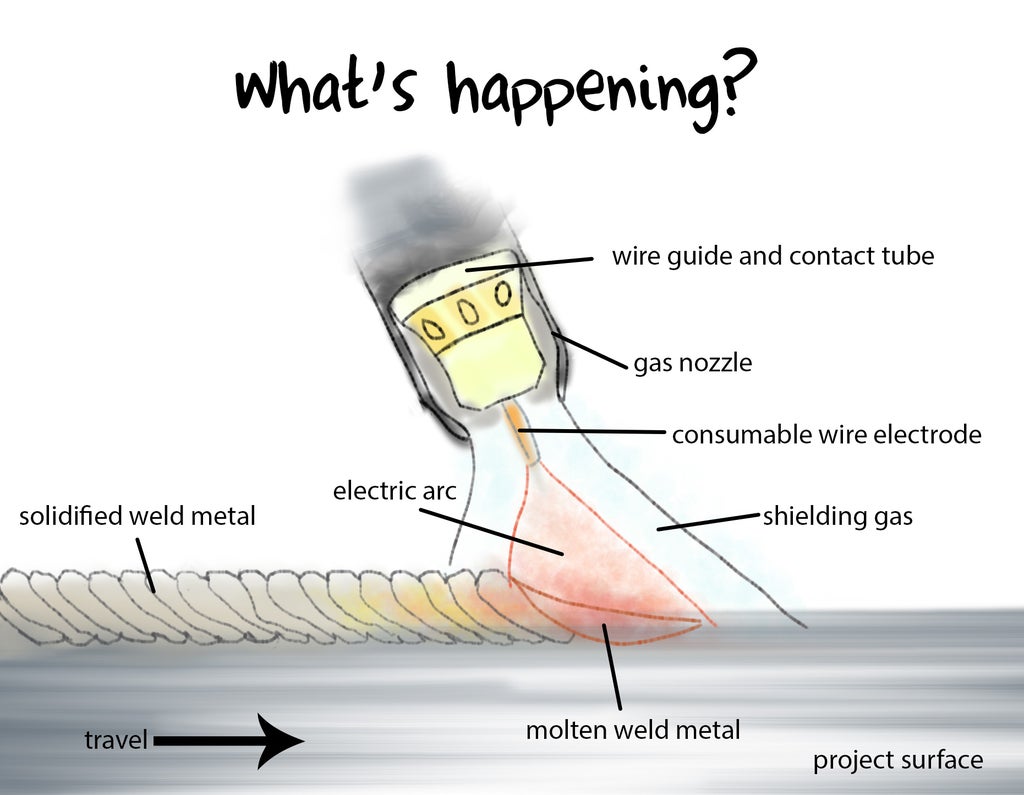

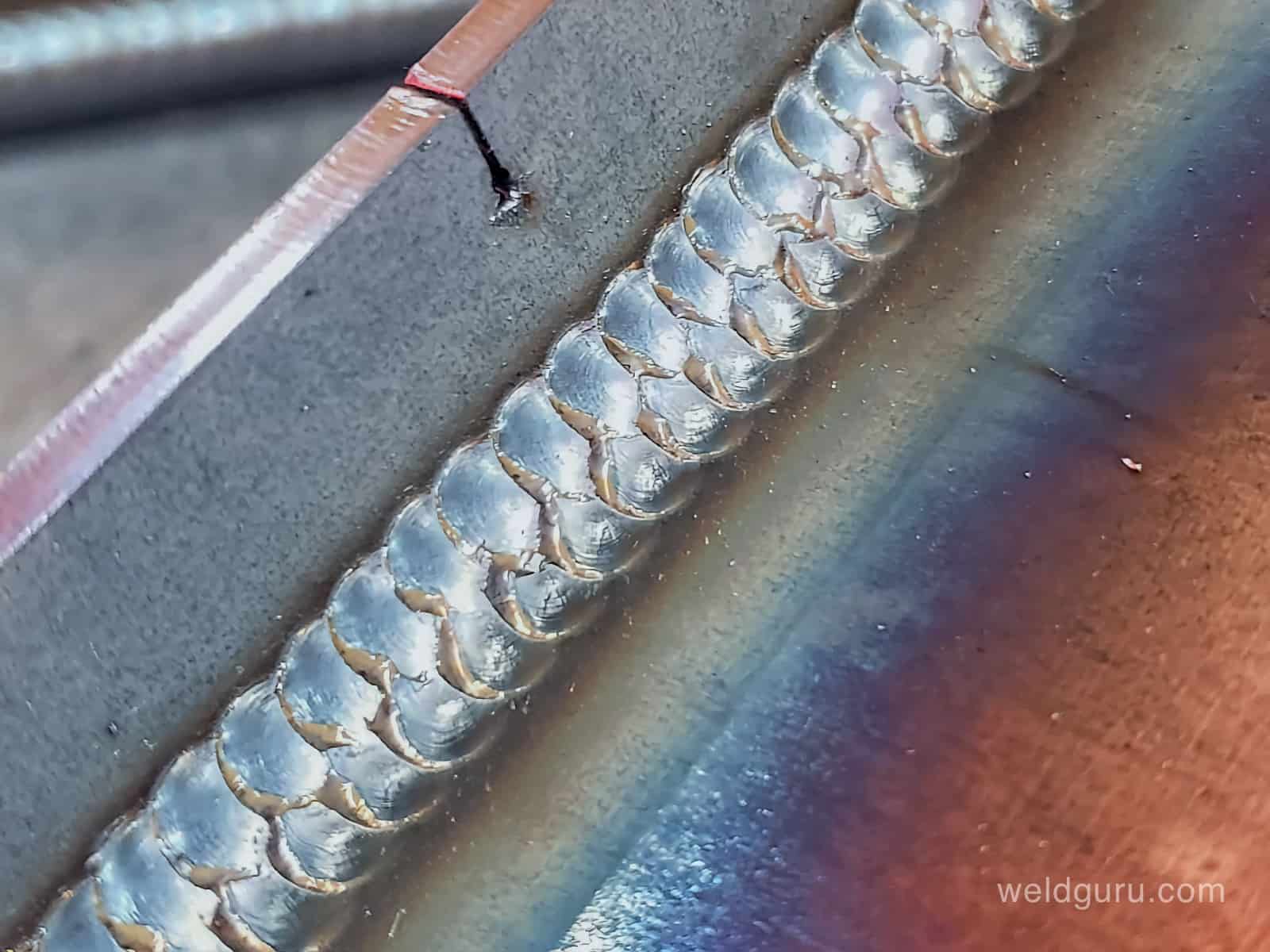

Beginner Mig Welding Patterns - Web mig welding tips. Patterns are essential for getting the weld’s quality appearance and efficiency. You need to watch out for overlap and the weld rolling over. Web everything you need to know from setup and settings to technique. Web 6 common mig weld patterns: We will explain each of these weaving techniques in this. Learn faster with an online welding course: Horizontal welding is a little harder. When & how to use them. The four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave pattern. Beginners should focus on maintaining a steady motion and avoid excessive weaving, as it may lead to inconsistent weld beads. Only after a lot of practice welding comfortably can a welder then weld in uncomfortable positions. Aside from machine settings, comfort is probably the number one contributing factor to a successful weld. Web the crescent pattern in mig welding, often. The process involves feeding a consumable wire electrode into the weld pool while a shielding gas protects the weld from atmospheric contamination. Web the 7 tips & tricks for beginner mig welding. Web as an amazon associate i earn from qualifying purchases. In mig welding, a continuous solid wire electrode is fed through a welding gun, along with a shielding. The filler rods used when stick welding can be pretty versatile and produce different welding bead patterns depending on the technique used. Just pull the trigger and squirt some met. Web some of the most commonly used welding electrodes include 7018, 7024, 7014, 6013, 6012, 6011 and 6010. As proof of this statement, metal inert gas welding gear can be. Web some of the most commonly used welding electrodes include 7018, 7024, 7014, 6013, 6012, 6011 and 6010. As proof of this statement, metal inert gas welding gear can be found pretty much everywhere. We created this video to help the beginner get st. Cart $ 0.00 type & hit enter. Aside from machine settings, comfort is probably the number. Mig welding is a versatile and popular welding process that can be used for various applications, such as fabrication, repair, and hobby projects. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. 7 mig welding weave patterns every beginner should learn mig welding, short for metal inert gas welding, is a. You need to watch out for overlap and the weld rolling over. There are many things to remember when setting up your mig welding machine. Web the crescent pattern in mig welding, often resembling a series of overlapping ‘u’ shapes, is a nuanced technique that involves a rhythmic forward and backward motion. Another tig welding technique you might have heard. Web how to mig weld for beginners: Just pull the trigger and squirt some met. Beginners should focus on maintaining a steady motion and avoid excessive weaving, as it may lead to inconsistent weld beads. The process involves feeding a consumable wire electrode into the weld pool while a shielding gas protects the weld from atmospheric contamination. Web the four. Web 6 common mig weld patterns: If you are welding with mild steel, then you can utilize any e70 or e60 stick electrode. Mig welding is a versatile and popular welding process that can be used for various applications, such as fabrication, repair, and hobby projects. Zigzag welding is achieved by moving the welding torch back and forth in a. There are many things to remember when setting up your mig welding machine. Cart $ 0.00 type & hit enter. 7 mig welding weave patterns every beginner should learn mig welding, short for metal inert gas welding, is a versatile and widely used welding process in various industries. Web whether you are restoring a project vehicle or building a custom. There are many things to remember when setting up your mig welding machine. Web 6 common mig weld patterns: Always keep it to a tight stringer beads on any joint. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. Cart $ 0.00 type & hit enter. Web the four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave $ 0.00. Always keep it to a tight stringer beads on any joint. Web some of the most commonly used welding electrodes include 7018, 7024, 7014, 6013, 6012, 6011 and 6010. The electrode should match the welded material and the amperage welding voltage needed to generate sufficient heat for the weld. Web the 7 tips & tricks for beginner mig welding. Web horizontal position mig welding techniques. Cart $ 0.00 type & hit enter. The material needs to be clean to get a good weld; Web how to mig weld for beginners: The filler rods used when stick welding can be pretty versatile and produce different welding bead patterns depending on the technique used. Horizontal welding is a little harder. You need to set up your. Web 6 common mig weld patterns: Remove any grease or oil before using abrasives. Web couple tips and tricks to making your flux cored arc welding (fcaw) or gasless mig welds looking awesome!yeswelder affiliate link (the little bit that comes. If you are welding with mild steel, then you can utilize any e70 or e60 stick electrode.

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips

Beginning to MIG Weld 11 Steps Instructables

Mastering MIG Welding Pattern Techniques A Complete Guide

How to MIG Weld MIG Welding 101 for Beginners YouTube

How to Mig weld for Beginners Positions, Patterns, Tips, Tricks and

4 Beginner MIG Welding Patterns to Master Today Beginner Welding Guide

MIG Welding for Beginners Video with Shauno from 4WD 24/7

6 Essential MIG Welding Patterns To Master

Mig Welding Basics Patterns

MIG Welding for Beginners YouTube

Just Pull The Trigger And Squirt Some Met.

The Mig Gun Should Be Pointing Upward Between 35 To 45 Degrees And Tilting About 15 To 35 Degrees Toward The Direction Of The Weld.

This Pattern Is Known For Its Ability To Control Heat Input, Making It Ideal For Welding Thinner Materials.

It’s One Of The Most Commonly Used Welding Processes, And It.

Related Post: