Acceptable Ring Gear Patterns

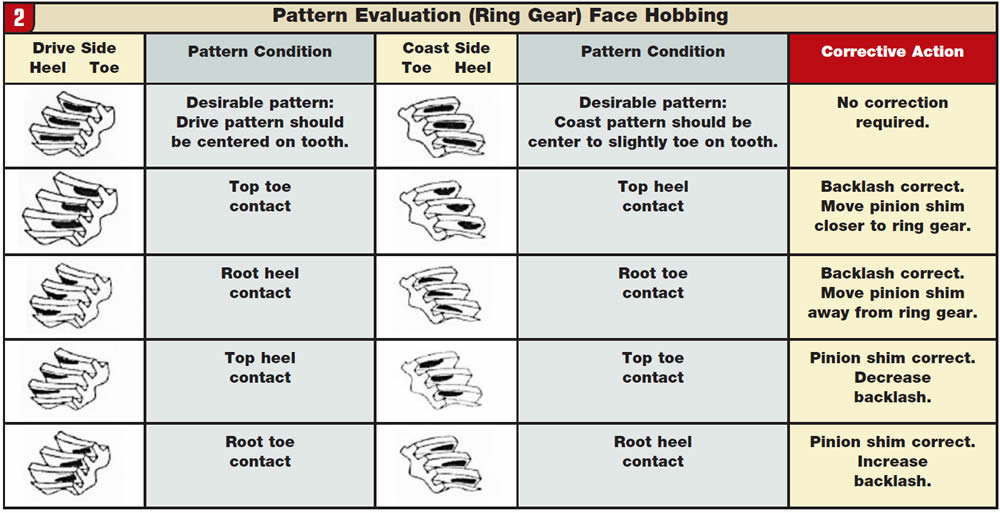

Acceptable Ring Gear Patterns - Web how to create & read ring gear patterns. Web no, your pattern is to one side. It should be set up evenly across the tooth. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Begin by setting proper pinion bearing preload, total turning preload, and ring. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Web in general, pattern movements can be summarized this way: Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web there are two types of gears which are determined by the machining method. Begin by setting proper pinion bearing preload, total turning preload, and ring. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set. The images bottom illustrate either acceptable and. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic. Alloy usa is a manufacturer of high strength chromoly axle shafts, kits and. Sequential graphic detail from too deep to. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. This chart illustrates different. The heel of the gear tooth is. One is manufactured by face hobbing, while the other one is manufactured by face. It should be set up evenly across the tooth. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Web check the tooth contact pattern to diagnose. Rotate the ring gear several times by hand and inspect the ring gear teeth. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web ring gear and pinion tooth contact pattern. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation.. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web in general, pattern movements can be summarized this way: Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Pulling off a proper differential setup comes down to. Web no, your pattern is to one side. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live. Rotate the ring gear several times by hand and inspect the ring gear teeth. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. It should be set up evenly across the tooth. Web move the ring gear away from the pinion (increase backlash) while maintaining minimum backlash. This chart. This chart illustrates different patterns and adjustments. One is manufactured by face hobbing, while the other one is manufactured by face. The order in which adjustments are made during differential assembly and setup are: Begin by setting proper pinion bearing preload, total turning preload, and ring. Rotate the ring gear several times by hand and inspect the ring gear teeth. Pulling off a proper differential setup comes down to precise. Web there are two types of gears which are determined by the machining method. Web check the tooth contact pattern to diagnose or after installing and adjusting a new ring and pinion gearset. Web move the ring gear away from the pinion (increase backlash) while maintaining minimum backlash. One is. Web move the ring gear away from the pinion (increase backlash) while maintaining minimum backlash. This chart illustrates different patterns and adjustments. Web there are two types of gears which are determined by the machining method. The heel of the gear tooth is. Web how to create & read ring gear patterns. Alloy usa is a manufacturer of high strength chromoly axle shafts, kits and. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or. Begin by setting proper pinion bearing preload, total turning preload, and ring. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web ring gear and pinion tooth contact pattern. Web shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Sequential graphic detail from too deep to to sha. Web in general, pattern movements can be summarized this way: Pulling off a proper differential setup comes down to precise. It should be set up evenly across the tooth.

Déjà Vu All Over Again Understanding RingandPinion Setup

How to Set up Your Rear Gear Correctly RacingJunk News

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

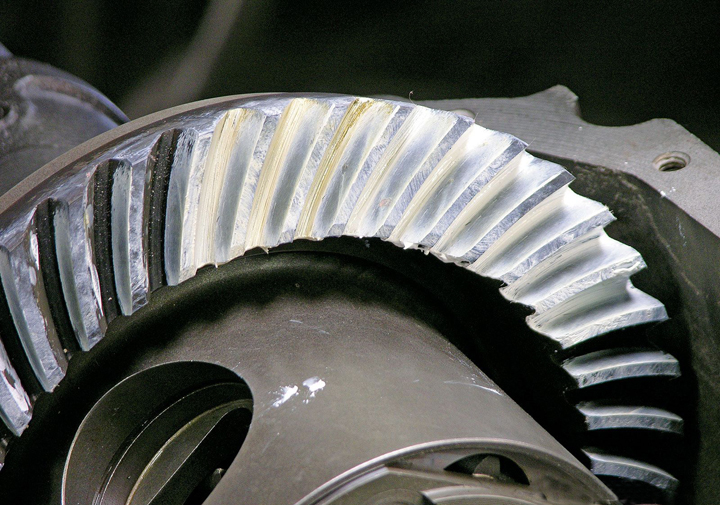

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring Gear And Pinion Pattern

Ring Gear Contact Pattern

How To Create & Read Ring Gear Patterns

Acceptable Ring Gear Patterns Patterns Kid

How to Select the Optimal Ring and Pinion Gears for a Dana Rear

Web Five Cut Ring & Pinion Gears (Face Milled):

Adjust This By Shimming The Ring Gear Carriage Left Or Right To Get The Correct Tooth Pattern.

Web This Video Was Created To Give People A Basic Understanding Of How To Read Gear Patterns When Setting Up Ring And Pinions.

Moving The Pinion Gear Closer To The Carrier Will Move The Drive Side Pattern Closer To The Flank And Slightly Toward The.

Related Post: