5 Lug Tightening Pattern

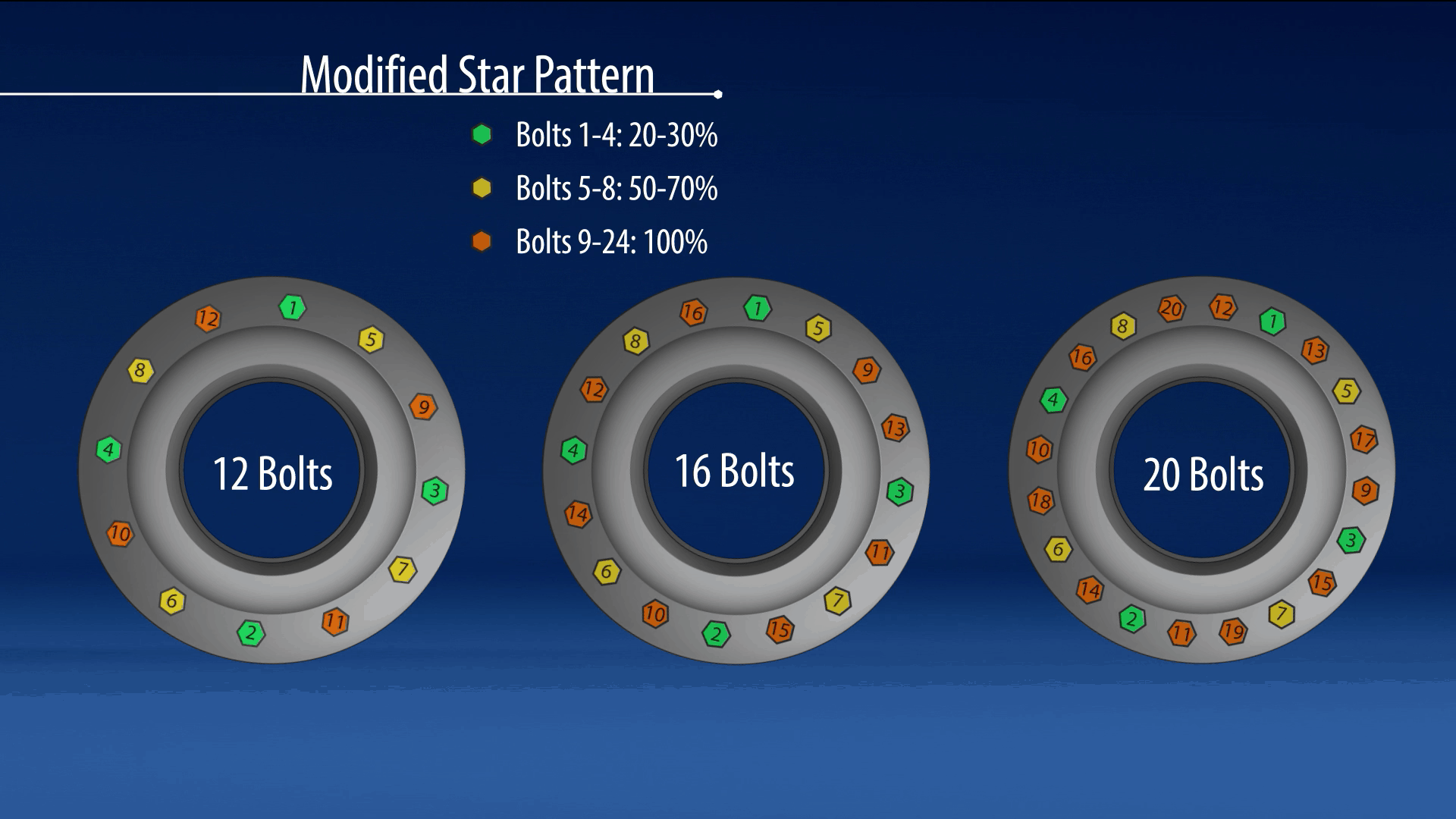

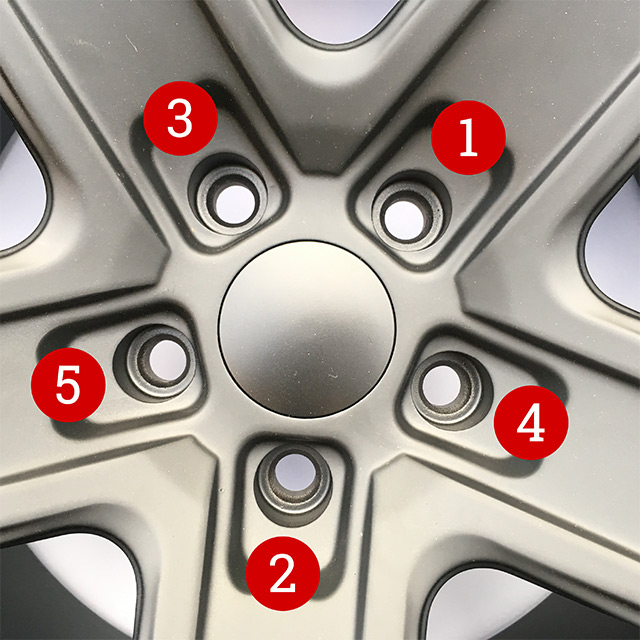

5 Lug Tightening Pattern - Used in the chemical industry for thin flanges and soft gaskets. Web tighten the lug nut: Install wheels and install lug nuts or bolt by hand. Next, tighten all lug nuts to approximately 1/2 specification using the same star pattern. But by following the correct procedures and taking the. Set the torque wrench to the right setting: Web start by tightening the lug nuts on the opposite sides of the wheel from each other, such as the top left lug nut and the bottom right lug nut. We recommend you start threading the hardware on by hand so as to not cross thread or strip the threads. Hand tighten all lug nuts using a star pattern. Common 5 lug bolt patterns include: The specific arrangement and spacing of these holes determine compatibility with various vehicles. Repeat the process for each lug nut. Web this pattern will ensure you are tightening your wheels evenly and adequately. Most manufacturers do not recommend using any lubricant or anti seize compound on the lugs. Use jack stands when appropriate. Tighten with the torque wrench: What’s different is how preload levels on the fasteners preload increase more rapidly with this approach. Web common bolt patterns have 4, 5, 6, or 8 lug holes, while less common have 3, 7, or 10 lug bolt patterns. Move to the one diagonally across, and screw that one on by hand. Install the wheel. Once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut. Move to the one diagonally across, and screw that one on by hand. What’s different is how preload levels on the fasteners preload increase more rapidly with this approach. Keep tightening in this manner until all the lug nuts are tight.. Most manufacturers do not recommend using any lubricant or anti seize compound on the lugs. Use jack stands when appropriate. You may see orders that are slightly different but be assured they all pretty much do the same thing. Install wheels and install lug nuts or bolt by hand. Repeat the process for each lug nut. Web start by tightening the lug nuts on the opposite sides of the wheel from each other, such as the top left lug nut and the bottom right lug nut. Web this pattern will ensure you are tightening your wheels evenly and adequately. Tighten with the torque wrench: Common 5 lug bolt patterns include: Web a 5 lug bolt pattern. What’s different is how preload levels on the fasteners preload increase more rapidly with this approach. Work in a criss cross pattern, tightening the nut that. Push the wheel home on the hub and using your socket wrench, tighten the wheel nuts just enough to hold the wheel snugly. It shouldn't be that one part of the tyre is extremely.. After that, keep going in a star pattern, alternating between the top, bottom, left, and right sides of the wheel, until all of the lug nuts are tight. The idea is to not distort the hub and rim with unevenly tightening of the bolts. To a novice, this all may seem more complex and overwhelming. This bolting pattern is good. Repeat the process for each lug nut. Web tighten the lug nut: Install wheels and install lug nuts or bolt by hand. It shouldn't be that one part of the tyre is extremely. If your wheels are in a 5 lug pattern, you are going to want to tight your wheels using this particular pattern: Tighten all lug nuts to full specification using the star pattern. 5×108 (or 5×4.25 in inches) 5×112. Your vehicle’s manual will provide the correct torque specification for your lug nuts. Look up the correct lug nut torque for the vehicle and adjust the setting on the torque wrench. The wrench will make a clicking sound when the correct torque has. Using the above diagram, tighten your lug nuts in the correct order that corresponds with the number of lug bolts your wheel has. If necessary, use a socket wrench to tighten the lugs just enough to hold the wheel on the vehicle. One thing that i have always hated on the diagrams that i have found on line was the. Tightening them in a cross pattern reduces the likelihood of things shifting and flexing, which means that your lugs will stay tight after you torque them. To a novice, this all may seem more complex and overwhelming. Run the lug nuts in with your favorite tool until snug, but no more. Web a 5 lug bolt pattern refers to wheels that have five holes for bolts. This reduces the likelihood of things shifting and flexing, which means that the nuts will stay tight even after you torque them. If necessary, use a socket wrench to tighten the lugs just enough to hold the wheel on the vehicle. Next, tighten all lug nuts to approximately 1/2 specification using the same star pattern. Web things can shift underneath even the tightest lug nut or bolt. Web once the car is fully lowered, remove the jack and stow it. Move to the one diagonally across, and screw that one on by hand. Web clean the wheel, hub faces and the center hole with a wire brush as well, then dry them. Look up the correct lug nut torque for the vehicle and adjust the setting on the torque wrench. Repeat the process for each lug nut. This bolting pattern is good for all asme b16.5 & b16.47, and heat. Using the above diagram, tighten your lug nuts in the correct order that corresponds with the number of lug bolts your wheel has. This means you should tighten one lug nut, then move to the lug nut opposite it, rather than moving to the one directly next to it.How to Diagnose and Repair Noisy Brakes YourMechanic Advice

How to Tighten Lug Nuts YourMechanic Advice

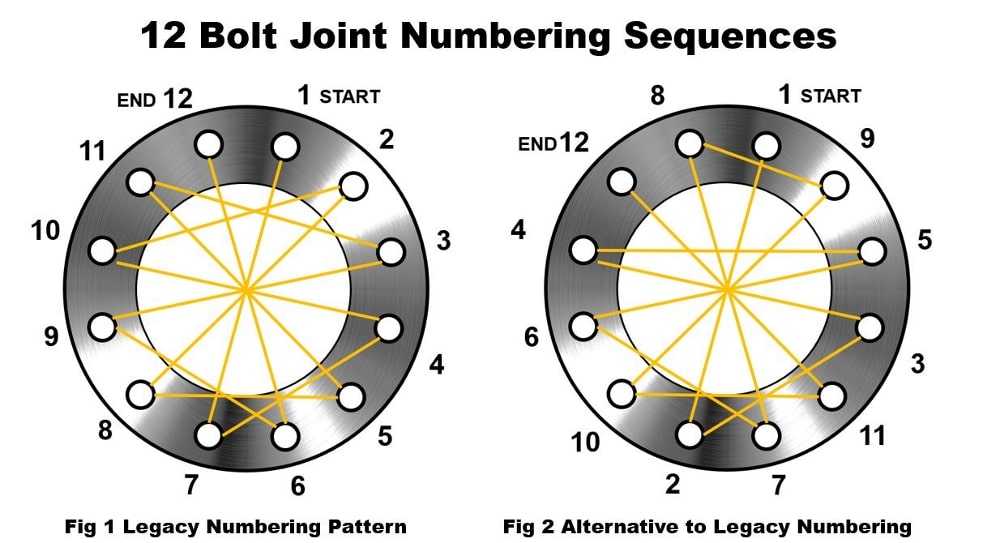

Bolt Tightening Sequence Why it Matters Enerpac Blog

Bolt Tightening Sequence and Restrictions Hex Technology

How to Change a Tire Les Schwab

Wheel Bolt Patterns & Typical Lug Nut Torque Specifications Quadratec

Wheel Lug Torque Sequence GTSparkplugs

/stp-500-481503701-5c4f9fc8c9e77c00014afc8f.jpg)

Wheel Lug Nut Tightening Order by Bolt Pattern

How to Measure a 5 Lug Trailer Axle Bolt Pattern Johnson Trailer Parts

5 Lug Bolt Pattern Template Johnson Trailer Parts

Be Sure To Put The Vehicle In Park And Apply The Emergency Brake.

You May See Orders That Are Slightly Different But Be Assured They All Pretty Much Do The Same Thing.

Web Here Are The Torque Sequence For Wheels With 4, 5, 6 And 8 Lugs.

The Specific Arrangement And Spacing Of These Holes Determine Compatibility With Various Vehicles.

Related Post: