40 Bolt Torque Pattern

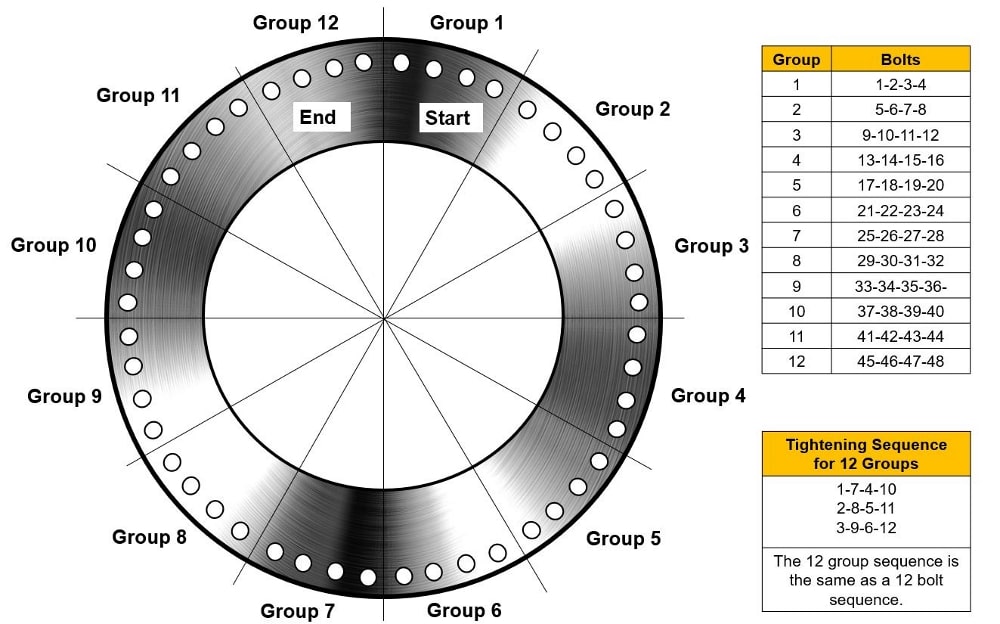

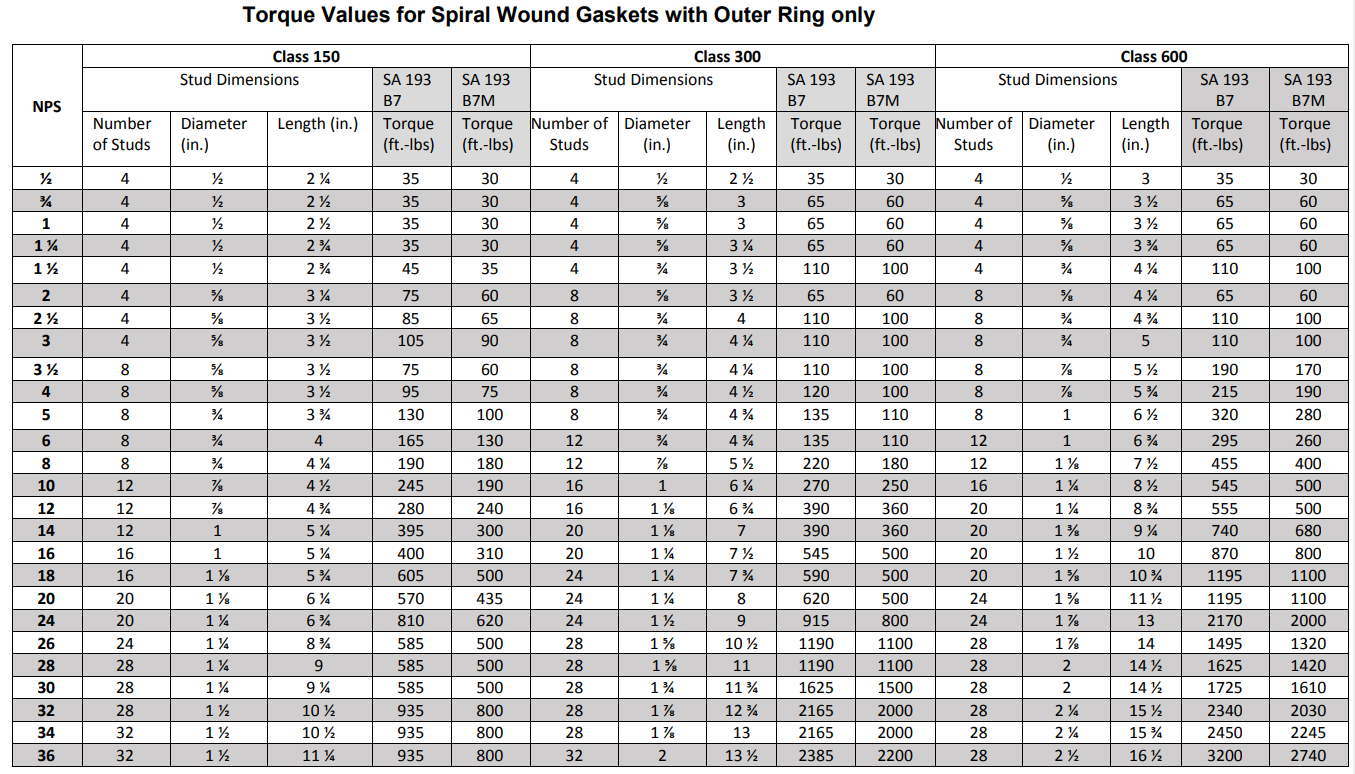

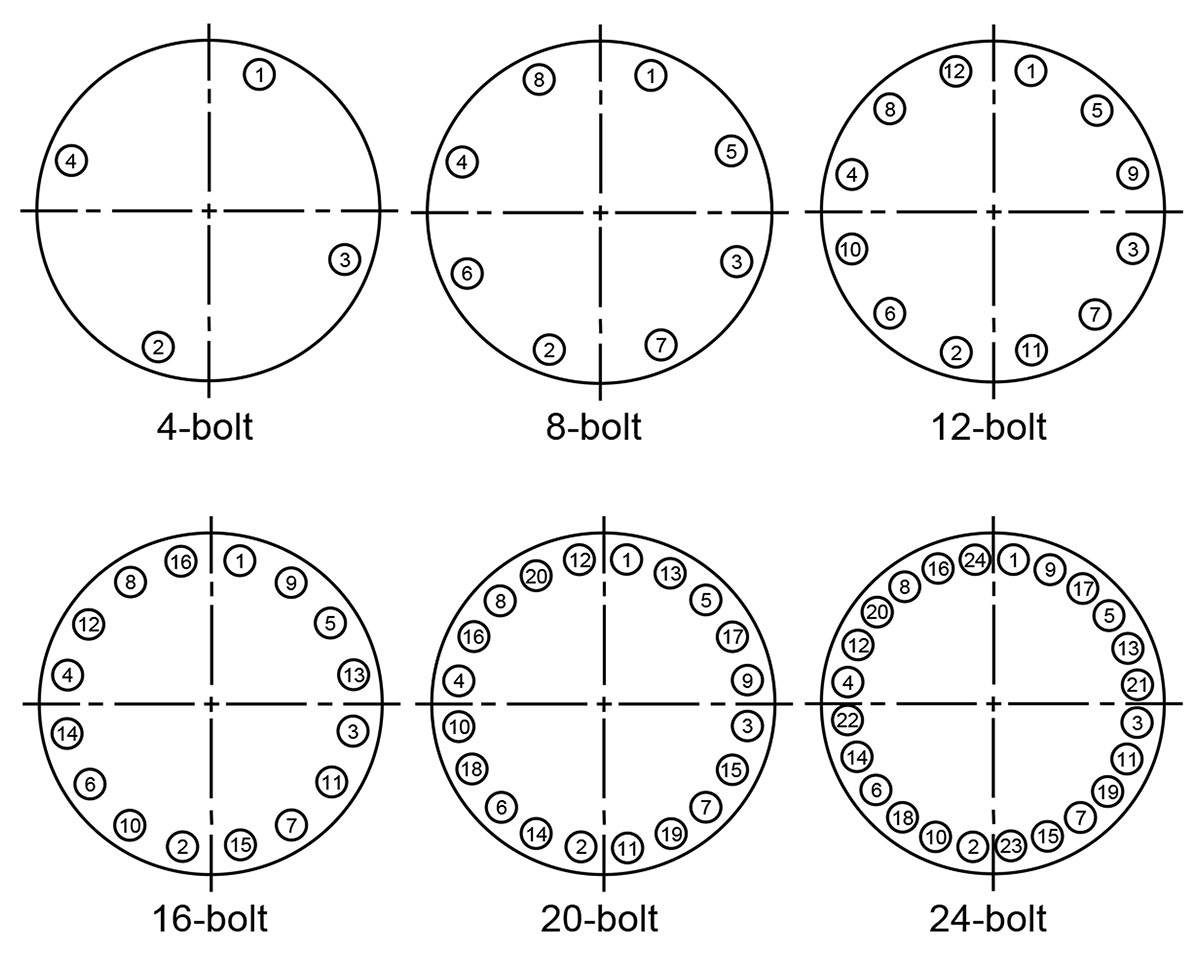

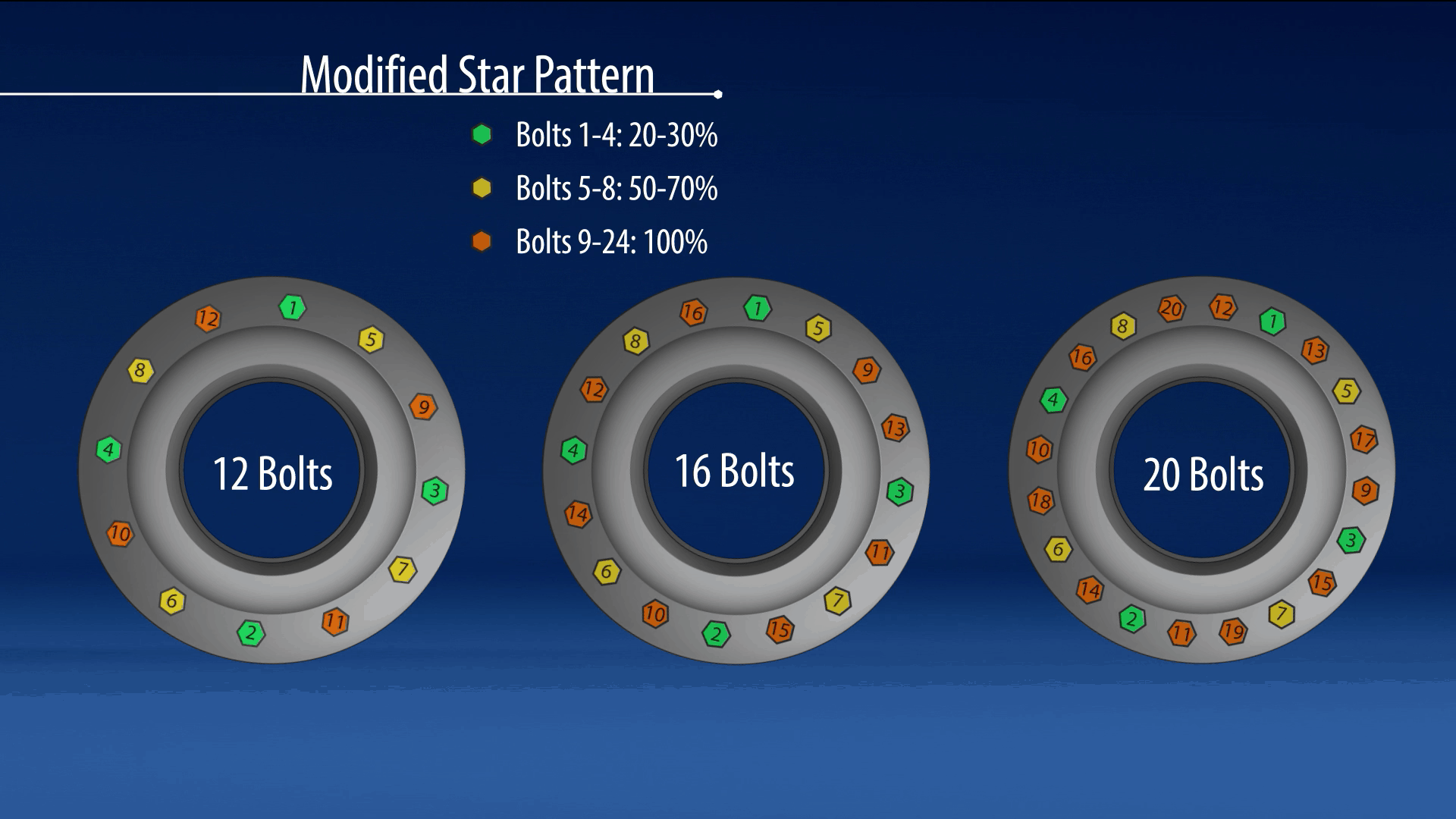

40 Bolt Torque Pattern - Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Use a calibrated torque tool: For dry bolts, the values should be increased by 30%. Web 30 rows bolt size: Web flanges with 40 bolts or more may use a bolt pattern for half. These general guidelines are to help identify potential pitfalls relating to the tightening of bolted joints. Determine bolt size — find the diameter and thread pitch of the bolt. Web bolt tightening patterns. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Web 1 2 4 3 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40. East pompano beach, fl 33060. Determine bolt size — find the diameter and thread pitch of the bolt. These. 1, 33, 25, 17, 9, 5, 13, 21, 29, 37, 3, 35, 27, 19, 11, 7, 15, 23, 31, 39, 2, 34, 26, 18, 10, 6, 14, 22, 30, 38, 4, 36, 28, 20, 12, 8, 16, 24, 32, 40. Web 1 2 4 3 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19. K = 0.15 k = 0.17 k = 0.20. Web 30 rows bolt size: Web to calculate the torque required to tighten a bolt: East pompano beach, fl 33060. These general guidelines are to help identify potential pitfalls relating to the tightening of bolted joints. The number bolts and tighten two bolts at each number. Web bolt tightening patterns. Use a calibrated torque tool: Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Use a calibrated torque tool: K = 0.15 k = 0.17 k = 0.20. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. The number bolts and tighten two bolts at each number. Web flanges with 40 bolts or more may use a bolt pattern for half. Web to calculate the torque required to tighten a bolt: #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Determine bolt size — find the diameter and thread pitch of the bolt. Web flanges with 40 bolts or more may use. Lookup flange bolt torque patterns on your. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. K = 0.15 k = 0.17 k = 0.20. Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. Use a calibrated torque. Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. East pompano beach, fl 33060. Lookup flange bolt torque patterns on your. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. The number bolts and tighten two bolts at each number. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. Lookup flange bolt torque patterns on your. Minimum preferred torque torque (ft.lbs.) (ft.lbs.) graphonic®. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. Web to calculate the torque required to tighten a bolt: The number bolts and tighten two bolts at each number. Determine bolt size — find the diameter and thread pitch of the bolt. Web 30 rows bolt size: Web bolt tightening patterns. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120. Web this table shows values for threads that have been lightly oiled and the tension is 70% of yield strength. Look up torque specification — use a torque. Web minimum preferred torque torque (ft.lbs.) (ft.lbs.) kammprofile. 1, 33, 25, 17, 9, 5, 13, 21, 29, 37, 3, 35, 27, 19, 11, 7, 15, 23, 31, 39, 2, 34, 26, 18, 10, 6, 14, 22, 30, 38, 4, 36, 28, 20, 12, 8, 16, 24, 32, 40. For dry bolts, the values should be increased by 30%. East pompano beach, fl 33060. Determine bolt size — find the diameter and thread pitch of the bolt. Lookup flange bolt torque patterns on your. Web 30 rows bolt size: K = 0.15 k = 0.17 k = 0.20. These general guidelines are to help identify potential pitfalls relating to the tightening of bolted joints. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web 1 2 4 3 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40. Use a calibrated torque tool:

Flange Bolt Torque Sequence UIP International Premium, 53 OFF

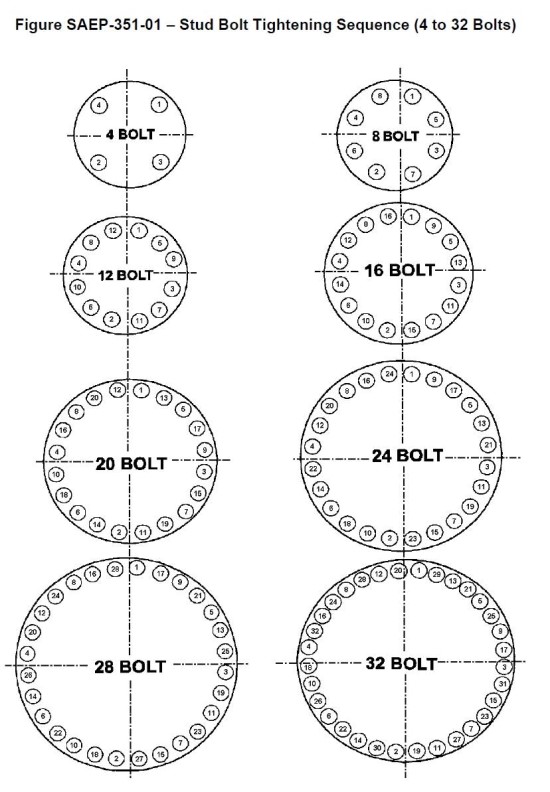

Bolting Patterns Westorc

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

8 Steps to Properly Installing a Gasket Triangle Fluid Controls Ltd.

Torque Charts Industrial Bolting and Torque Tools

Bolt Tightening Sequence and Restrictions Hex Technology

Metric Bolt Torque Chart Large PDF

Torque Charts Industrial Bolting and Torque Tools

Bolt Torque Table Asme Elcho Table

Web To Calculate The Torque Required To Tighten A Bolt:

Minimum Preferred Torque Torque (Ft.lbs.) (Ft.lbs.) Graphonic®.

The Number Bolts And Tighten Two Bolts At Each Number.

Web Flanges With 40 Bolts Or More May Use A Bolt Pattern For Half.

Related Post: